A kind of bearing steel ball surface strengthening processing equipment

A bearing steel ball and surface strengthening technology, which is applied in metal processing equipment, grinding/polishing equipment, surface polishing machine tools, etc., can solve the problems of limited capacity, low consistency of strengthening processing, and affecting processing efficiency, etc., to increase Probability of collision impact, improvement of strengthening processing efficiency, effect of increasing collision probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

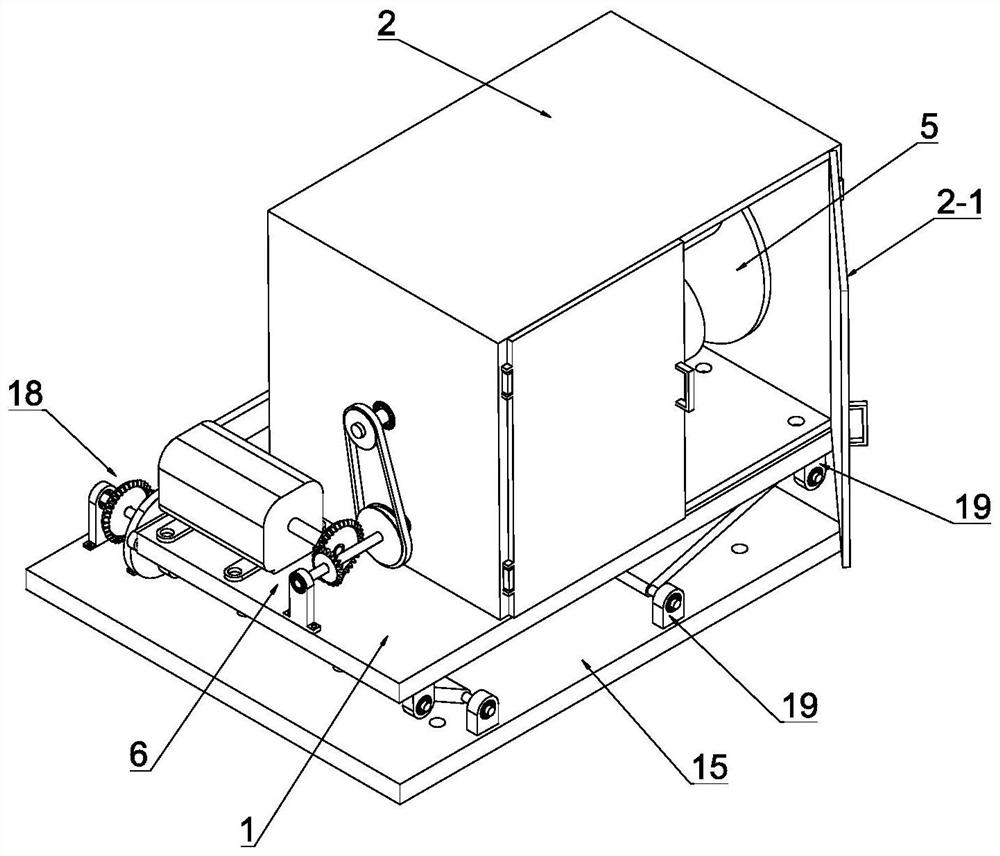

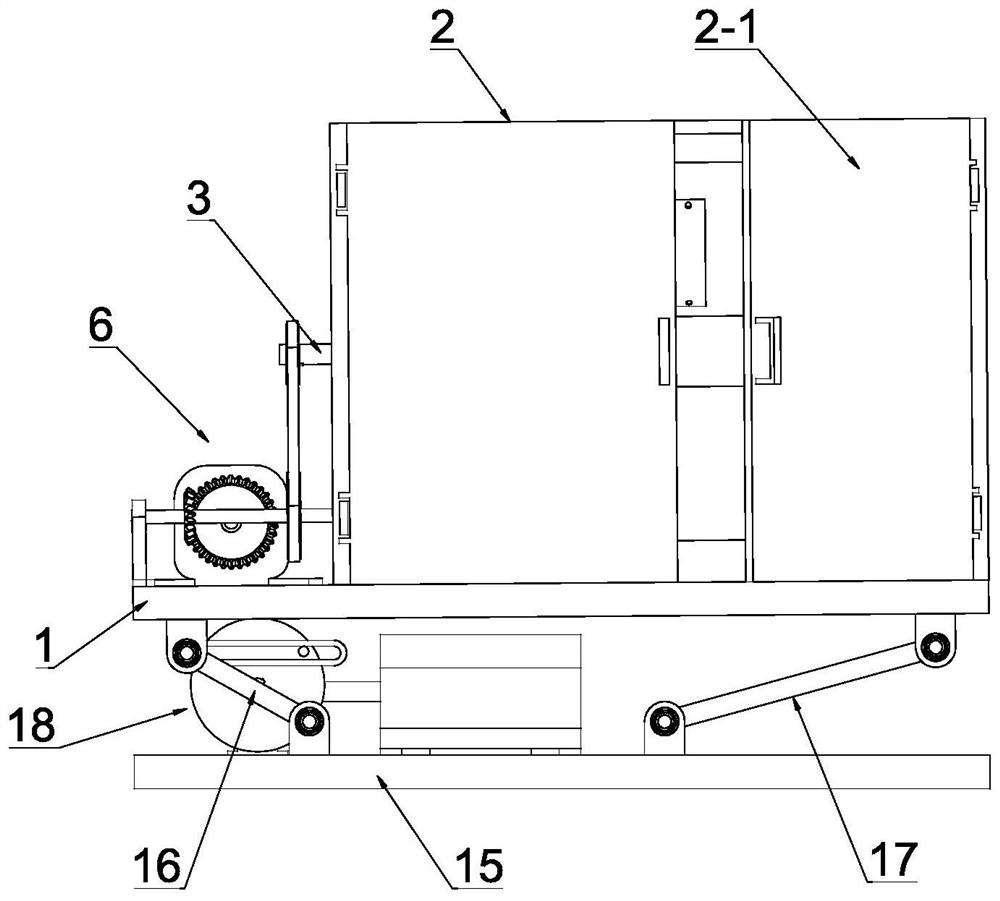

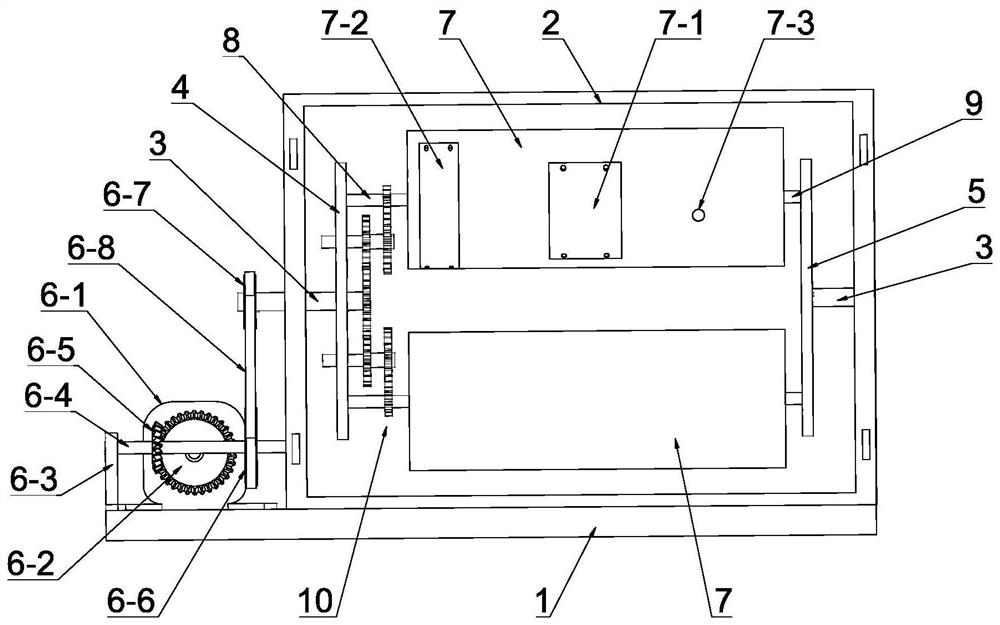

[0046] see Figure 1-Figure 2 , this embodiment discloses a bearing steel ball surface strengthening processing equipment, including a bottom plate 1, a strengthening processing device arranged on the bottom plate 1 for strengthening the surface of the bearing steel ball, and a device arranged at the lower end of the bottom plate 1. A reciprocating rocking mechanism for driving the strengthening processing device to reciprocate.

[0047] see Figure 1-Figure 3 and Figure 6 The strengthening processing device includes a cabinet 2 arranged on the bottom plate 1, a horizontal shaft 3 arranged on both ends of the cabinet 2 through bearing rotation, a rotation drive mechanism 6 for driving the rotation of the horizontal shaft 3, The driving turntable 4 and the driven turntable 5 respectively fixedly arranged at the two ends of the horizontal rotating shaft 3; wherein, two rollers 7 parallel to the horizontal rotating shaft 3 are arranged between the driving turntable 4 and the dr...

Embodiment 2

[0098] see Figure 12-Figure 17 , other structures in this embodiment are the same as in Embodiment 1, the difference is that the bearing steel ball strengthening mechanism is an ultrasonic vibration mechanism 20, and the ultrasonic vibration mechanism 20 includes a vibrating plate 20 arranged in the drum 7 -1. Ultrasonic generator 20-2 and a plurality of ultrasonic vibrators 20-3 arranged at the lower end of the vibrating plate 20-1, wherein, a baffle 21 is provided inside the drum 7, and the baffle 21 separates the The interior of the drum 7 is divided into an installation cavity 22 and an intensified processing cavity 23, the ultrasonic generator 20-2 is arranged in the installed cavity 22, the vibration plate 20-1 and the ultrasonic vibrator 20-3 are arranged in the intensified processing cavity 23, a plurality of ultrasonic vibrators 20-3 are connected to the ultrasonic generator 20-2 through a high-frequency line 20-4. With the above-mentioned structure, on the one hand...

Embodiment 3

[0106] The other structures in this embodiment are the same as those in Embodiment 1, except that the chassis 2 can be a frame or a support or other structures that can fix the horizontal rotating shaft 3 on the bottom plate 1 .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com