Automatic separation control method for metal foreign objects in tobacco shreds

A technology for automatic separation of metal foreign matter, applied in the field of tobacco production, can solve the problems of waste, labor-consuming tobacco leaves, and the inability to automatically separate tobacco leaves from metal, so as to achieve automatic separation and improve the effect of separation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The following embodiments illustrate the technical solutions of the present invention in detail. The following embodiments are only exemplary, and can only be used to explain and illustrate the technical solutions of the present invention, and cannot be construed as limiting the technical solutions of the present invention.

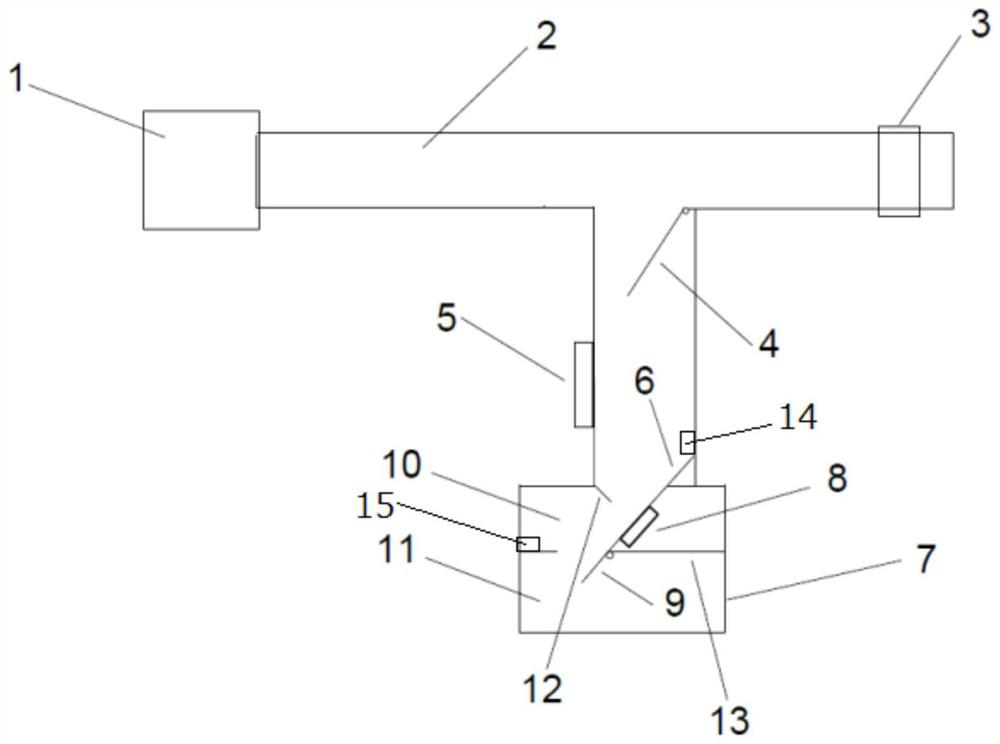

[0031] Such as figure 1 As shown, the tobacco leaves to be cut are conveyed to the shredder 1 through the tobacco conveying device. A first metal detector 3 is provided at the front end of the tobacco conveying device 2, and a tobacco conveying device between the first metal detector and the shredder A blanking port is provided on the upper part, and the first metal detector is connected with the controller (not shown in the figure) with electrical signals, and transmits the detected metal signal to the controller.

[0032] The blanking channel is a circular blanking channel or a square blanking channel. In other embodiments of the present application, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com