Press-holding system and press-holding method

A valve and hand-held technology, applied in the field of medical devices, can solve problems such as inability to effectively protect the valve, failure to prevent valve rebound, and valve fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

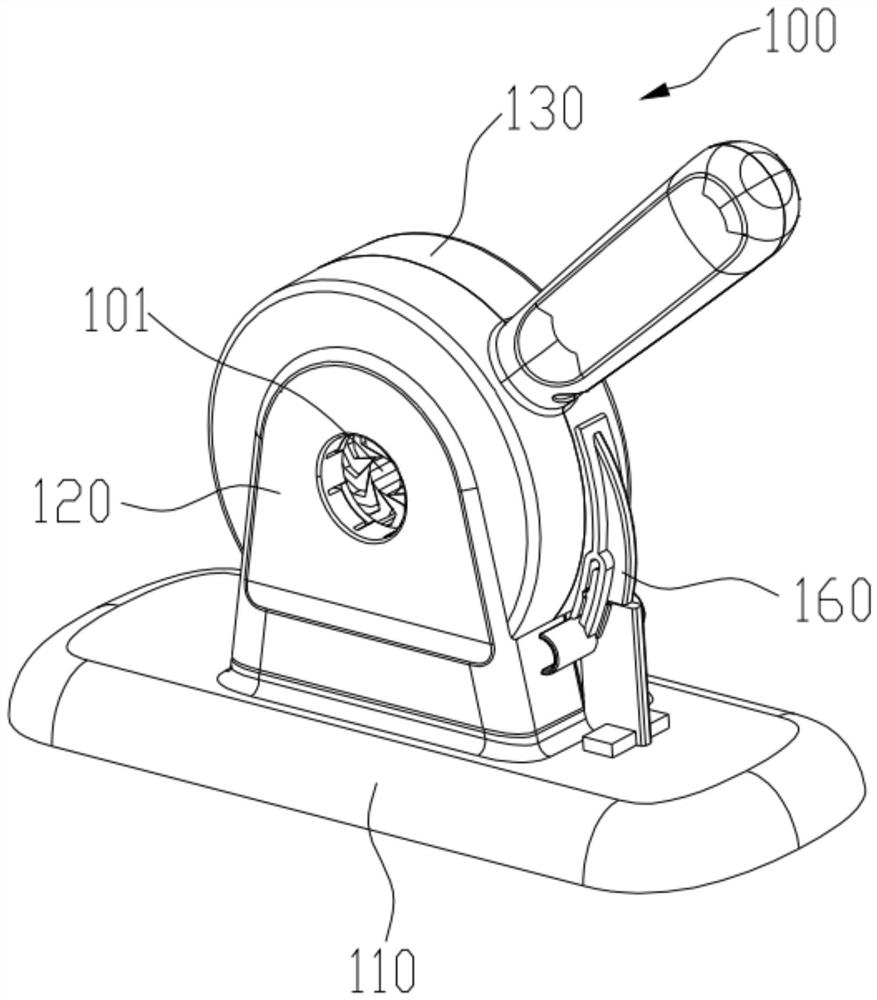

[0098] Such as Figure 1-Figure 20As shown, the present embodiment provides a valve crimping system for installing a valve on a delivery device for valve replacement surgery. The crimping system includes a valve crimping machine 100, a hand-held crimping device 200, a crimping sponge 300 and a crimping film 400, wherein the valve crimping machine 100 is used to crimp the valve in the first stage, and the hand-held crimping device 200 For the second stage of crimping the valve. The crimping sponge 300 is used in the first stage of crimping. The crimping sponge 300 has a cylindrical structure. A good valve and the crimping sponge 300 are placed on the designated position of the conveyor (i.e. Figure 20 The conveyer crimping section 600 shown in ), when crimping, put the assembled valve, crimping sponge 300 and the conveyor into the crimping port 101 of the valve crimping machine to pass through the valve crimping machine 100 pairs The valve undergoes the first stage of crimp...

Embodiment 2

[0127] This embodiment provides a crimping method, including a first-stage crimping and a second-stage crimping, wherein the first-stage crimping is used to crimp the valve through the valve crimping machine 100, and after crimping, it is used to prevent the valve from returning. In the second stage of crimping, the hand-held crimping device 200 is used to continuously crimp the valve until the operation begins, thereby improving the efficiency of the operation.

[0128] Specifically, the above-mentioned first-stage crimping includes:

[0129] S1. Soak the crimping sponge 300 in physiological saline for a first set time and then take it out. Preferably, the first set time is 3 minutes. In this embodiment, before crimping, the crimping sponge 300 is soaked in physiological saline for 3 minutes. During the first stage of crimping, the crimping sponge 300 will release the internal water when squeezed, thereby protecting the leaflets of the valve from Tear due to drying and stre...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com