Steam electric heating continuous sterilizer

A sterilizer and electric heating technology, applied in lighting and heating equipment, food science, food preservation, etc., can solve the problems of unsatisfactory sterilizing effect and inability to realize continuous production of bactericide, and achieve controllable sterilizing time and simple structure , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings, so that the advantages and features of the present invention can be more easily understood by those skilled in the art, so as to define the protection scope of the present invention more clearly.

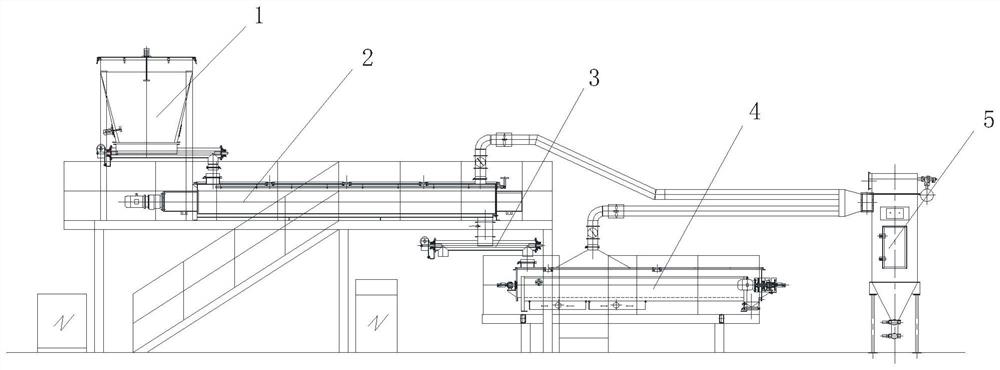

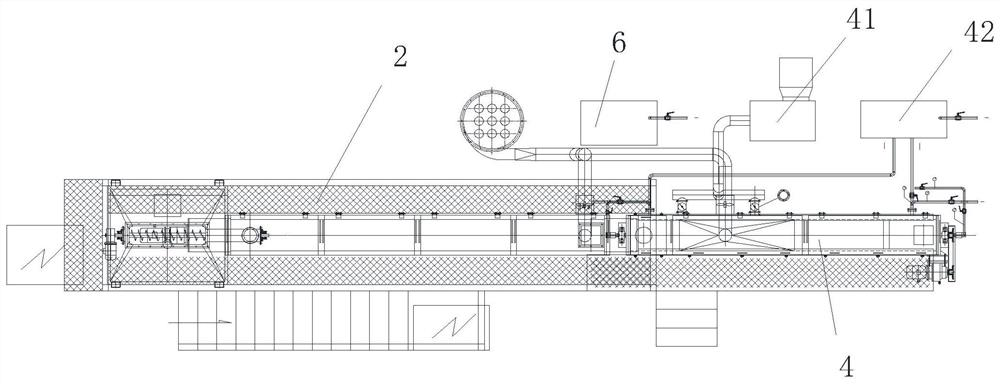

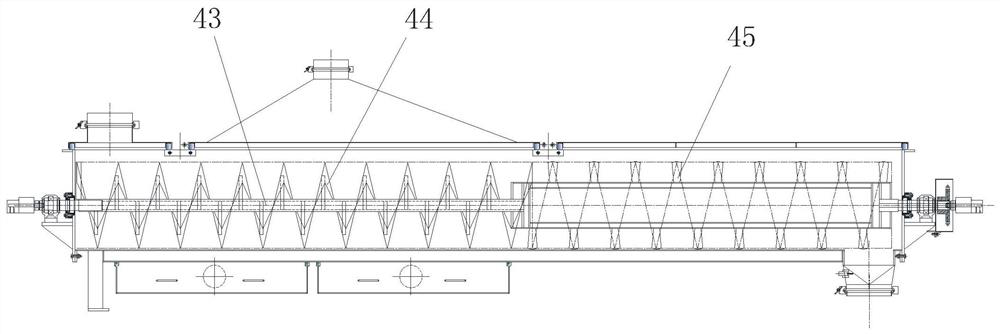

[0031] like figure 1 , figure 2 A steam electric heating continuous sterilizer, comprising a quantitative feeding system 1, an electric heating screw conveyor 2, a bidirectional screw conveyor 3, a cooling screw conveyor 4, a dry heat steam system 6 and a dust removal system 5 arranged in sequence.

[0032] The rack platform is used to connect and support the above-mentioned equipment to ensure the normal operation of all parts of the system, reduce vibration, and facilitate operation and maintenance.

[0033] The quantitative feeding system 1 is used for quantitative feeding, and is composed of a storage box, a feeding auger, a support column ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap