Small glass bottle having increased chemical resistance

A technology for glass and active pharmaceutical ingredients, used in glass blowing, glass molding, glass manufacturing equipment, etc., can solve the problems of reduced chemical stability, high production costs, and limited stability of quartz glass coatings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

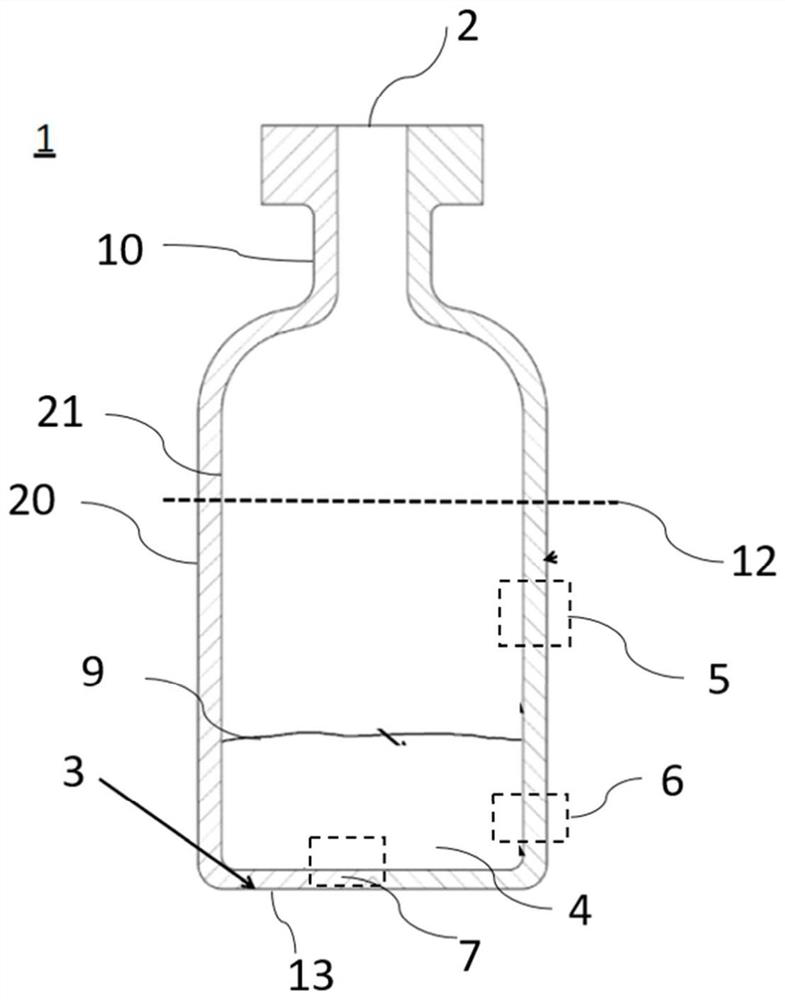

[0145] figure 1A schematic cross-section of a glass vial 1 filled with a liquid 4 is shown. The glass vial 1 comprises a base 3 and walls 20 , 21 , which merge in the upper region of the glass vial 1 into a neck region 10 and end in a rim 11 . The walls form an outer wall 20 and an inner wall 20 , and only the inner wall 20 is in contact with the liquid 4 . The middle plane 12 of the container is defined by the bottom surface 13 of the base.

[0146] The rim volume of the glass vial 1 is less than 4.5 ml, which rim volume is understood to mean the entire inner volume of the glass vial up to the upper edge 11 . The actual filling volume 9 is determined by the volume of the liquid 4 . According to the invention, the fill volume 9 is at least four times smaller than the edge volume 11 . Thus, the fill level of the glass vial 1 (quotient of fill volume 9 and rim volume 11 ) is less than 0.25.

[0147] Due to the low filling level, the liquid mainly covers the inner wall 7 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com