Model-free integral sliding mode control method of ultrasonic motor servo system

An ultrasonic motor, integral sliding mode technology, applied in the direction of AC motor control, general control strategy, estimation/correction of motor parameters, etc., can solve the problem of difficult to fully compensate the nonlinearity of ultrasonic motor servo system.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] Embodiments of the invention are described in detail below, examples of which are illustrated in the accompanying drawings. The embodiments described below by referring to the figures are exemplary only for explaining the present invention and should not be construed as limiting the present invention.

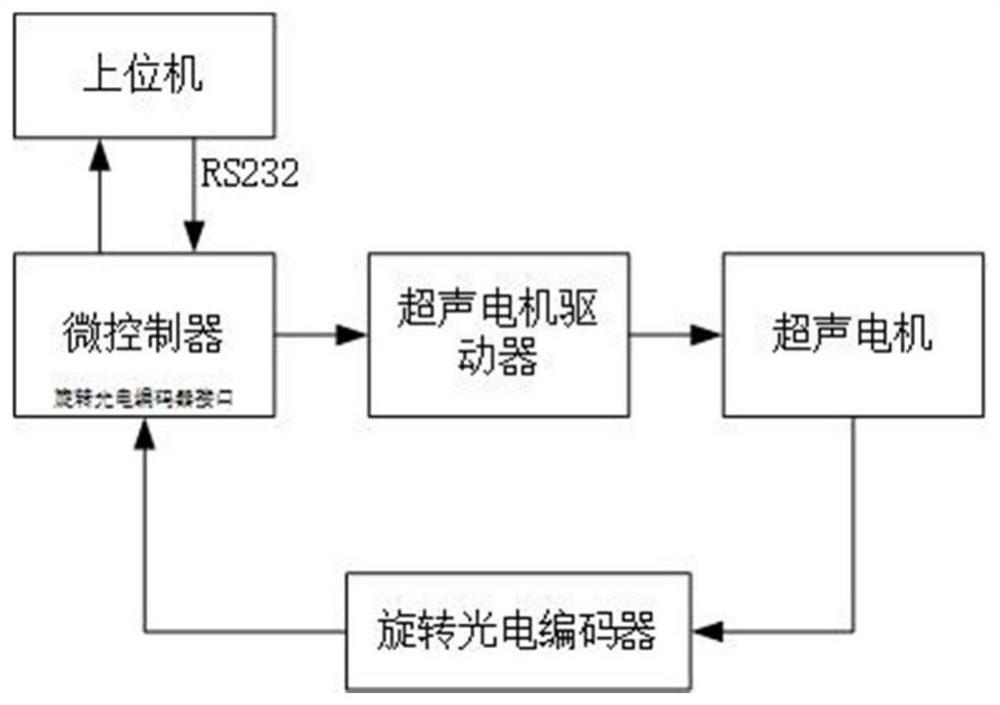

[0044] A model-free integral sliding mode control method of an ultrasonic motor servo system according to the present invention, the rotary servo system relied on mainly includes a microcontroller, an ultrasonic motor driver, an ultrasonic motor, and a photoelectric rotary encoder, such as figure 1 shown.

[0045] Among them, the microcontroller is the core of the servo system, including the model-free integral sliding mode controller operation module, the expected input signal response module, the UART interface module with FPGA, the motor start and stop response module, the motor forward and reverse response module, the incremental Type photoelectric encoder interface...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com