Preparation method of flexible sulfur positive electrode of lithium-sulfur battery

A technology for lithium-sulfur batteries and sulfur cathodes is applied in the field of preparation of flexible sulfur cathodes for lithium-sulfur batteries, which can solve the problems of lack of short-range electronic conductivity, limited binding capacity, and large pores of three-dimensional carbon skeleton.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

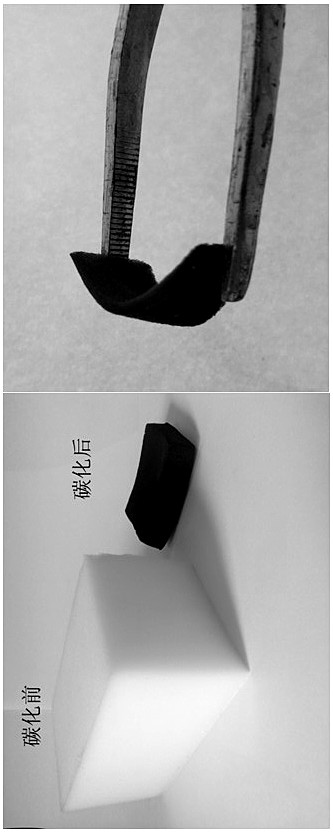

Embodiment 1

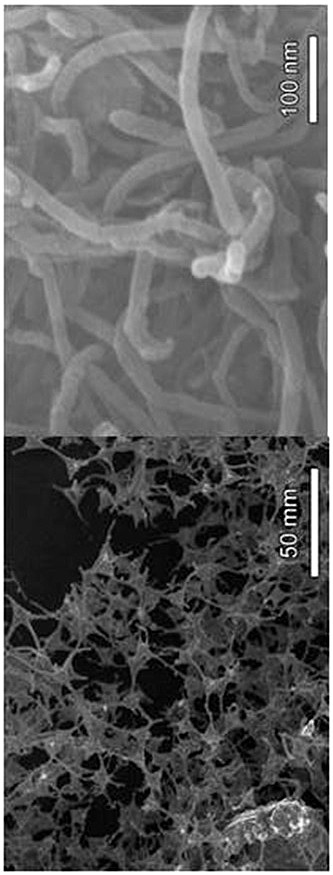

[0023] The preparation method of the flexible multifunctional carbon foam of this embodiment comprises the following steps: soak the melamine foam in ethylene glycol for 6 hours, then ultrasonically treat it for 0.5 hour, wash it with distilled water for 3 times, and then dry it in a vacuum oven at 60°C 12h prepared carbon precursor, immersed in 100mL containing 1mM Co(NO 3 ) 2 ·6H 2 O and 1g of thiourea in ethanol solution, stir evenly, then ultrasonically treat until it is fully impregnated, in a nitrogen atmosphere at a heating rate of 3°C / min, first raise the temperature to 550°C and keep it for 2h, then raise the temperature to 800°C and keep it for 2h, then cool naturally to room temperature to obtain flexible multifunctional carbon foam.

[0024] The preparation method of the positive electrode of the lithium-sulfur battery of the present embodiment comprises the following steps: mixing the flexible multifunctional carbon foam prepared above with elemental sulfur powd...

Embodiment 2

[0027] The preparation method of the flexible multifunctional carbon foam of this embodiment comprises the following steps: soak the melamine foam in acetone for 3 hours, then ultrasonically treat it for 0.5 hour, wash it with distilled water for 3 times, and then dry it in a vacuum oven at 120°C for 8 hours. To obtain carbon precursor, immerse in 50mL containing 4mM CoCl 2 ·6H 2 O and 2g of thioacetamide in ethanol solution, stir well, then ultrasonically treat it until it is fully impregnated, in a nitrogen atmosphere at a heating rate of 3°C / min, first raise the temperature to 500°C and keep it for 1h, then raise the temperature to 850°C and keep it for 0.5h , naturally cooled to room temperature to obtain flexible multifunctional carbon foam.

[0028] The preparation method of the positive electrode of the lithium-sulfur battery in this embodiment includes the following steps: immerse the flexible multifunctional carbon foam prepared above in a carbon disulfide solution w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Discharge specific capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com