Photovoltaic module containing multilayer packaging adhesive film and preparation method thereof

A photovoltaic module and encapsulation adhesive film technology, which is applied in photovoltaic power generation, adhesives, electrical components, etc., can solve the problems of easy precipitation of POE film surface additives, low yield, and POE film has not been improved, and achieve excellent anti-corrosion PID performance, the effect of improving production yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

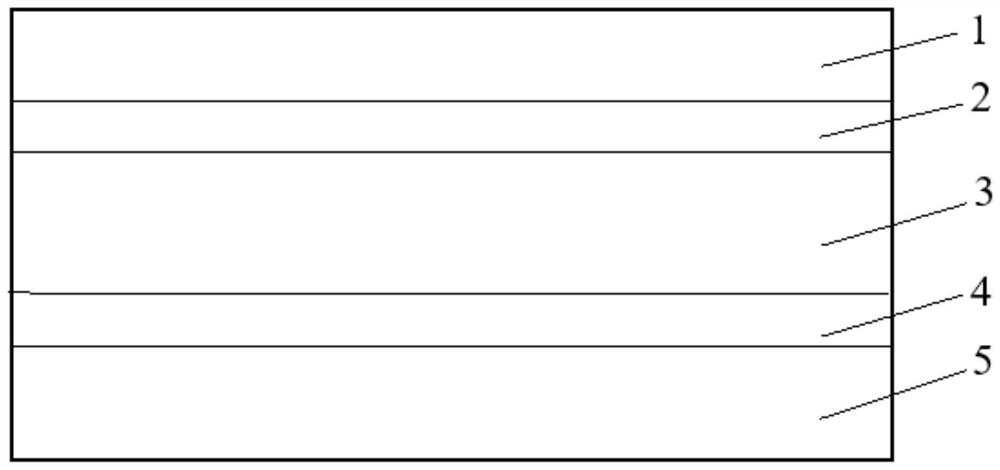

[0082] The photovoltaic module containing multi-layer encapsulation adhesive film of this embodiment, the front plate, upper layer adhesive film, cell sheet, lower layer adhesive film and rear plate that are arranged in sequence from top to bottom, wherein, the front plate and rear plate are glass plates, The upper adhesive film is a single-layer EVA adhesive film, the cell is a P-type cell, and the lower adhesive film is a three-layer adhesive film of EVA+POE / POE / EVA+POE;

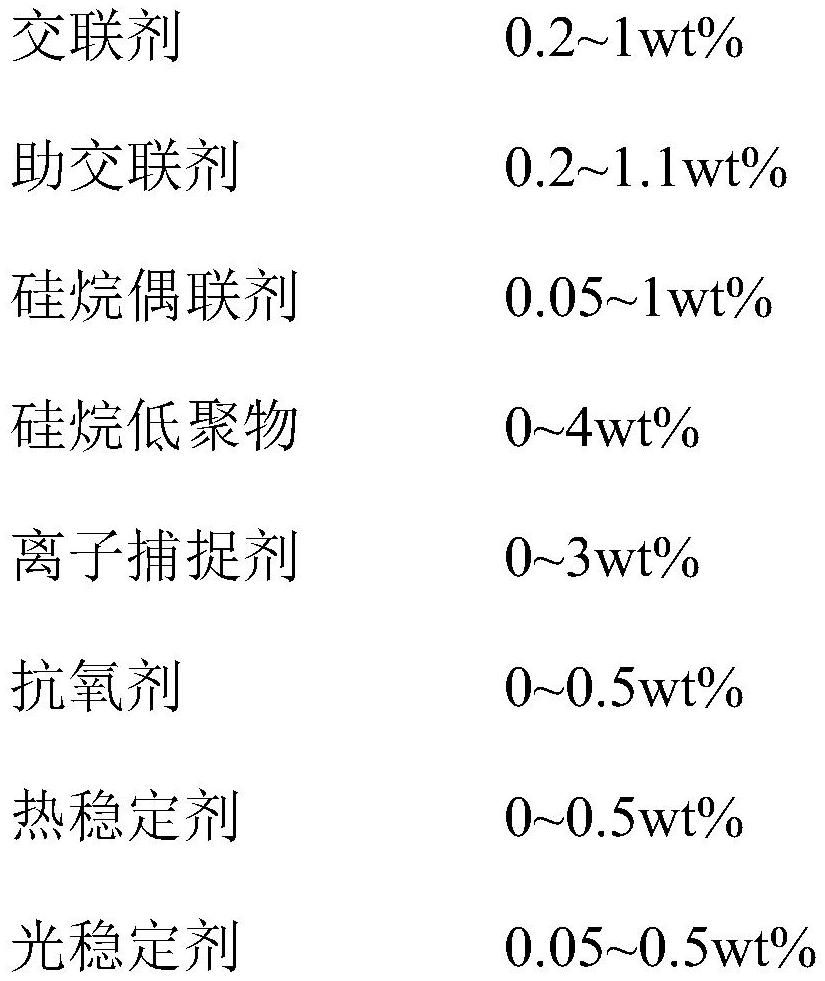

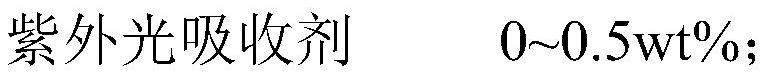

[0083] Wherein, by mass percentage, the specific composition of the upper surface layer EVA+POE adhesive film of the lower layer adhesive film is:

[0084]

[0085] Wherein, in terms of mass percentage, the specific composition of the lower surface EVA+POE film is:

[0086]

[0087]

[0088] Wherein, in terms of mass percentage, the specific composition of the middle layer POE film is:

[0089]

[0090] The preparation method of the photovoltaic module containing the multi-layer encapsulation ...

Embodiment 2

[0093] The photovoltaic module containing multi-layer encapsulation adhesive film of this embodiment, the front plate, upper layer adhesive film, cell sheet, lower layer adhesive film and rear plate that are arranged in sequence from top to bottom, wherein, the front plate and rear plate are glass plates, The upper adhesive film is a single-layer EVA adhesive film, the cell is a P-type cell, and the lower adhesive film is a three-layer adhesive film of EVA+POE / POE / EVA+POE;

[0094] Wherein, by mass percentage, the specific composition of the upper surface layer EVA+POE adhesive film of the lower layer adhesive film is:

[0095]

[0096] Wherein, in terms of mass percentage, the specific composition of the lower surface EVA+POE film is:

[0097]

[0098] In terms of mass percentage, the specific composition of the middle layer POE film is:

[0099]

[0100]

[0101] The preparation method of the photovoltaic module containing the multi-layer encapsulation adhesive ...

Embodiment 3

[0104] The photovoltaic module containing multi-layer encapsulation adhesive film of this embodiment, the front plate, upper layer adhesive film, cell sheet, lower layer adhesive film and rear plate that are arranged in sequence from top to bottom, wherein, the front plate and rear plate are glass plates, The battery sheet is a P-type battery sheet, and the upper and lower adhesive films are all three-layer adhesive films of EVA+POE / POE / EVA+POE;

[0105] Wherein, in terms of mass percentage, the specific composition of the upper surface layer EVA+POE adhesive film of the upper layer adhesive film and the lower layer adhesive film is:

[0106]

[0107]

[0108] Wherein, in terms of mass percentage, the specific composition of the lower surface layer EVA+POE adhesive film of the upper layer adhesive film and the lower layer adhesive film is:

[0109]

[0110] In terms of mass percentage, the specific composition of the middle layer POE film of the upper film and the low...

PUM

| Property | Measurement | Unit |

|---|---|---|

| cross-linking degree | aaaaa | aaaaa |

| transmittivity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com