Method for predicting dynamic recrystallization type rheological stress of Nb microalloyed steel

A flow stress, microalloyed steel technology, applied in the intersection of steel research and machine learning, can solve the problems of unpredictable flow stress curve, Nb microalloyed steel patent publication, limited application scope, etc., to achieve wide applicability, The effect of improving efficiency and accuracy, and wide applicability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

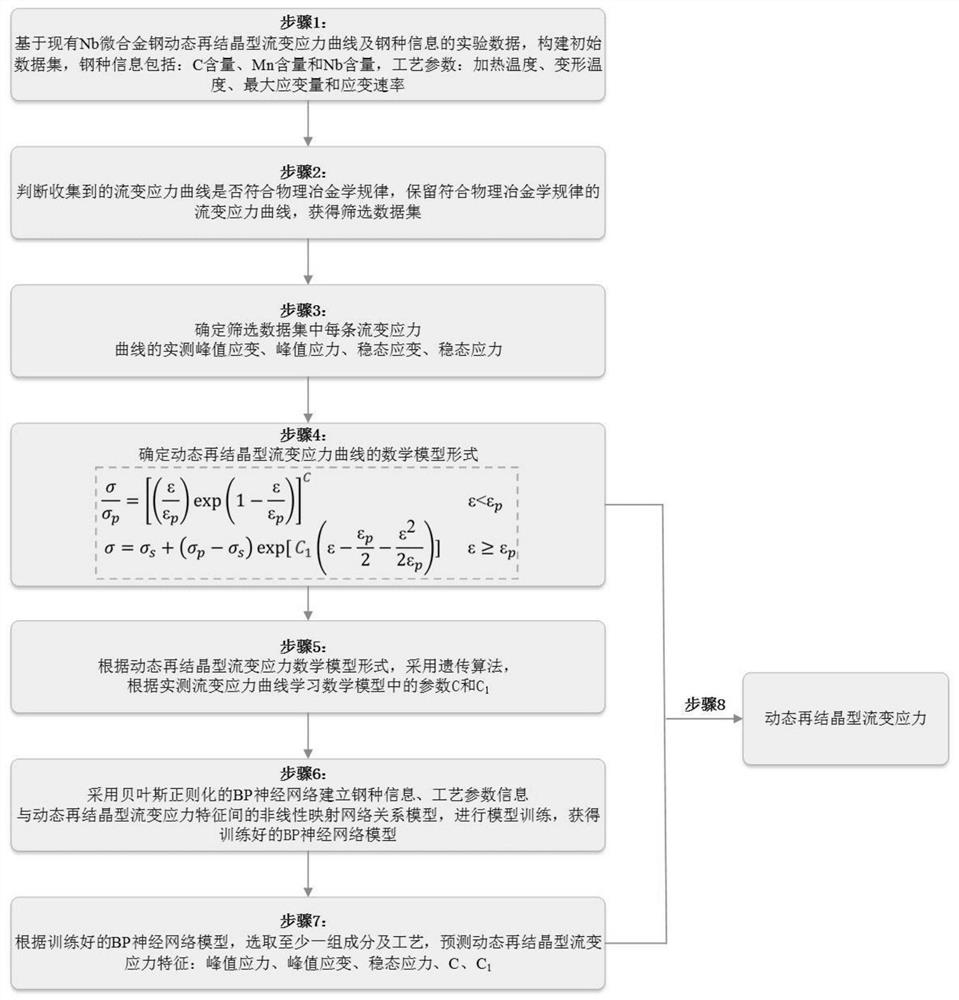

[0041]A method for predicting the dynamic recrystallization flow stress of Nb microalloyed steel, the flow chart is as follows figure 1 shown, including the following steps:

[0042] Step 1. Based on the existing 500 dynamic recrystallization flow stress curves of Nb microalloyed steel, experimental data of steel type information and process parameter information, an initial data set is constructed. The steel type information includes: C content, Mn content and Nb content content; process parameters include: heating temperature, deformation temperature, maximum strain and strain rate;

[0043] Step 2. Judging whether the collected 500 flow stress curves conform to the laws of physical metallurgy. The specific judgment criteria are: ① judging whether the flow stress curves conform to the laws of physical metallurgy under different deformation conditions of the same component. For example, under the conditions of different deformation temperatures of the same composition, as th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com