Method for improving insulation and thermal aging resistance of oiled paper of converter transformer and testing method

A converter transformer, oil-paper insulation technology, applied in the direction of applying stable tension/pressure to test material strength, test ship construction, test dielectric strength, etc. Internal insulating structure, the effect of improving thermal aging resistance and improving breakdown strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

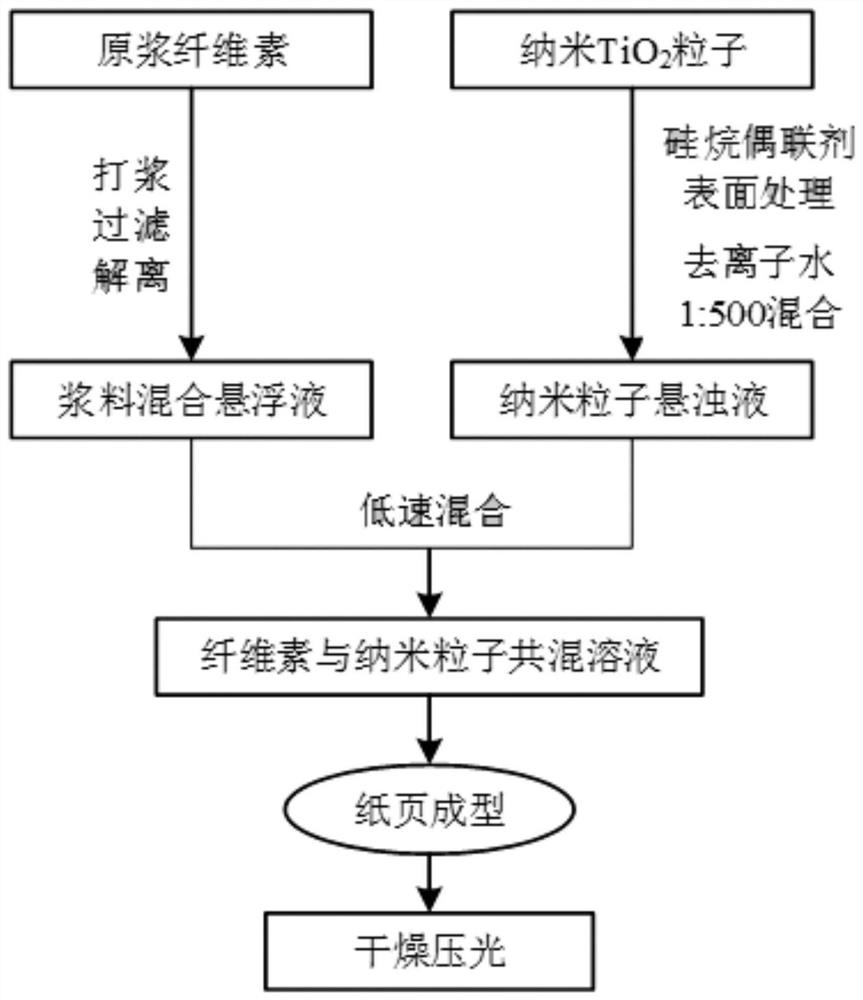

[0050] This embodiment discloses a method for improving the thermal aging resistance of converter transformer oil-paper insulation, including the following preparation steps,

[0051] Step 1, material selection and pretreatment: select 9-11nm nano-TiO 2 As a modified nano-filler, first use the silane coupling agent KH-550 to nano-TiO 2 Carry out surface pretreatment;

[0052] Step 2, prepare the suspension: select deionized water with a conductivity of 8-12 μS / cm to disperse the nanoparticles pretreated in step 1, and modify the particles TiO 2 The mass ratio with deionized water is 1:(450-550), and then it is made into a suspension;

[0053] Step 3, stirring the suspension: mechanically stirring the suspension obtained in step 2;

[0054] Step 4, prepare the mixed liquid: use a beater to beat the raw pulp cellulose, filter and dissociate to obtain a mixed suspension of the slurry, and then mix the nano-TiO contained in step 3 2 Add the suspension into the beaten pulp and ...

Embodiment 2

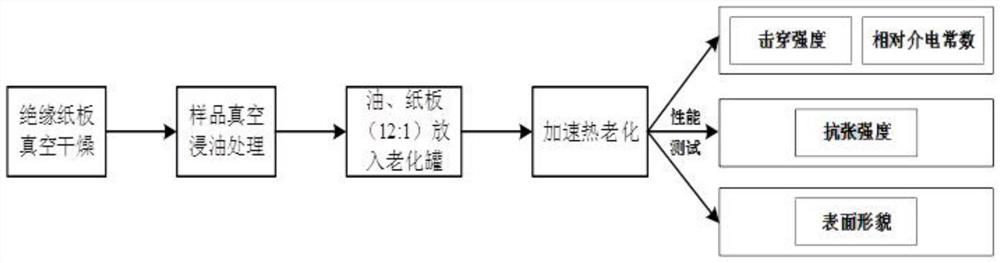

[0062] This embodiment is further optimized on the basis of Embodiment 1. In actual use, nano-TiO 2 Modified cellulose oil paper can be vacuum dried and soaked in oil.

[0063] The temperature for drying the oil paper sample in a vacuum drying oven is 105°C, the vacuum degree is 50Pa, and the drying time is 48 hours. The oil is No. 25 transformer oil that has been filtered to remove gas, moisture and impurity particles inside the oil; dry The finished oil paper sample and the treated transformer oil were immersed in oil in a vacuum environment, the oil immersion temperature was 40° C., the vacuum degree was 50 Pa, and the time was 24 hours.

[0064] Wherein, the oil paper obtained after oil immersion and the treated transformer oil are put into an aging tank, and the mass ratio of the transformer oil to the oil paper in the aging tank is about 12:1.

[0065] Through this method, the composite insulation of mineral oil-insulating paper is modified, and nano-TiO is produced 2 ...

Embodiment 3

[0067] This embodiment discloses a method for testing the performance of oil paper in a converter transformer, which is mainly for testing the electrical and mechanical performance of the oil paper in Embodiment 1 of the present invention; it includes the following steps:

[0068] Step 1: Vacuum drying and oil immersion treatment of insulating oil paper;

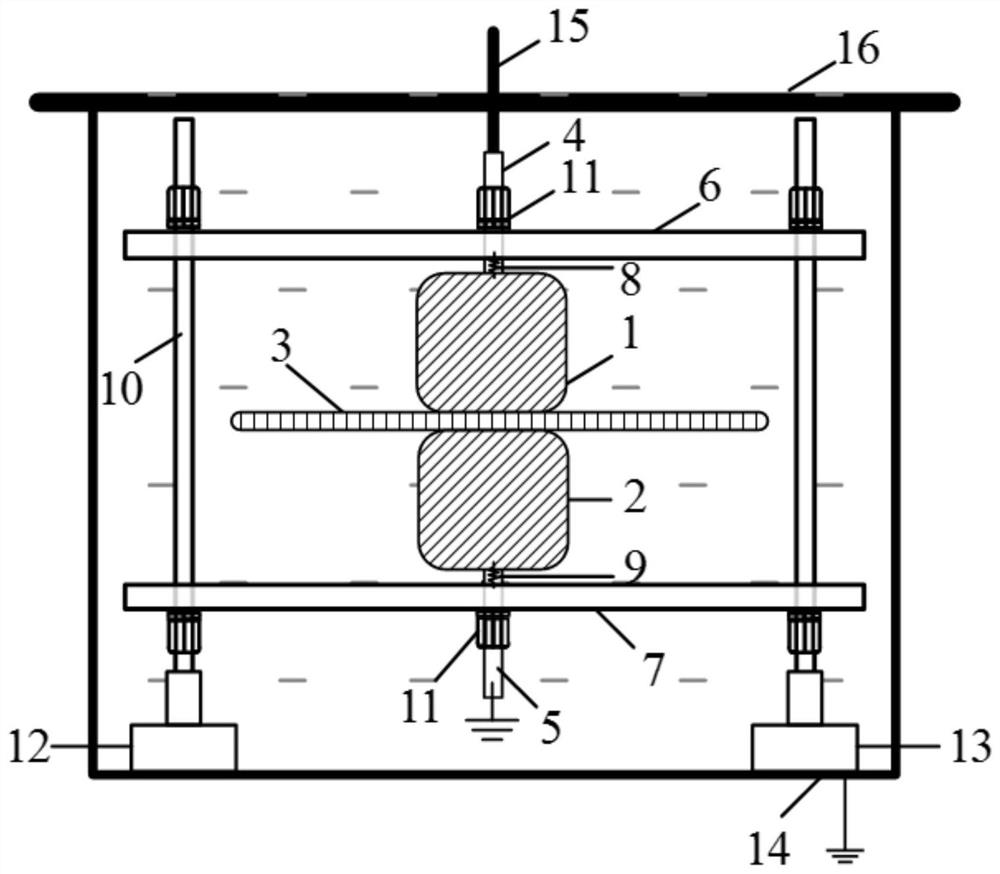

[0069] Step 2: Set up a control test group and put the samples in the control test group into the aging tank to seal;

[0070] Step 3: Put the aging tank containing the sample into the aging box for accelerated thermal aging;

[0071] Step 4: Regularly sample, observe and test, measure electrical and mechanical properties, and compare the aging state of cellulose oil paper through oil, paper color and scanning electron microscope (SEM);

[0072] Among them, the specific process of step 1 is as follows: the temperature of drying the oil paper sample in a vacuum drying oven is 105 ° C, the vacuum degree is 50 Pa, and the dryi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| electrical conductivity | aaaaa | aaaaa |

| electrical conductivity | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com