In-situ contrast experiment device and method for single-factor corrosion of gas in composite corrosion factors

A corrosion factor, control experiment technology, applied in the direction of measuring devices, weather resistance/light resistance/corrosion resistance, instruments, etc., can solve the problems of complex experimental process, large environmental pollution, danger, etc., to simplify the experimental steps and ensure the authenticity Strong and practical effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] In order to make the above objects, features and advantages of the present invention more comprehensible, the present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments.

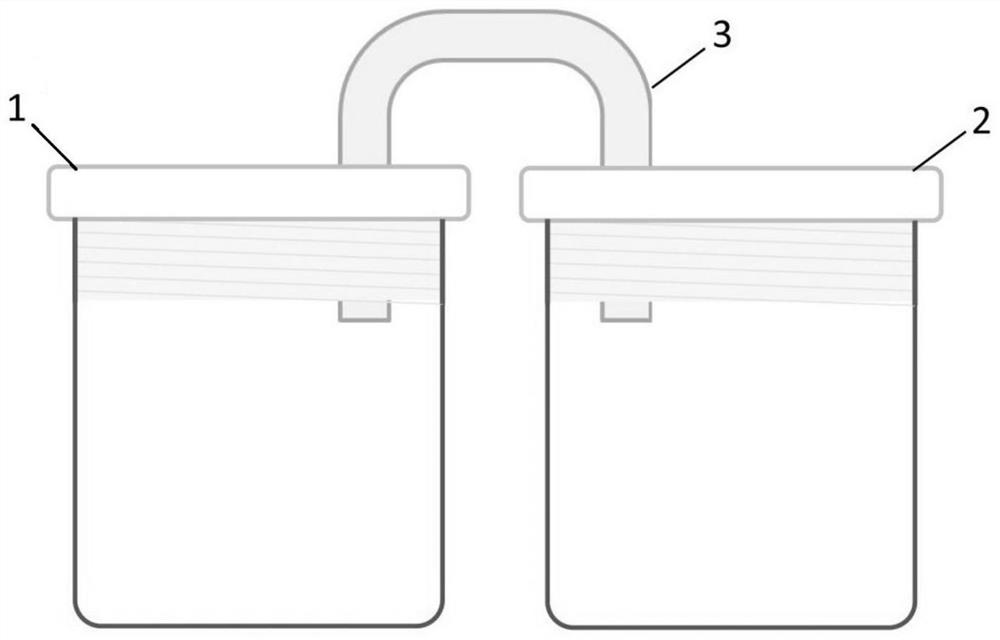

[0031] like figure 1 As shown, the in-situ control experimental device for gas single-factor corrosion in a kind of composite corrosion factor of the present embodiment includes a main chamber 1 for composite corrosion and at least one sub-chamber 2 for gas single-factor corrosion. The top of the chamber 1 communicates with the top of the sub-chamber 2 through a trachea 3 .

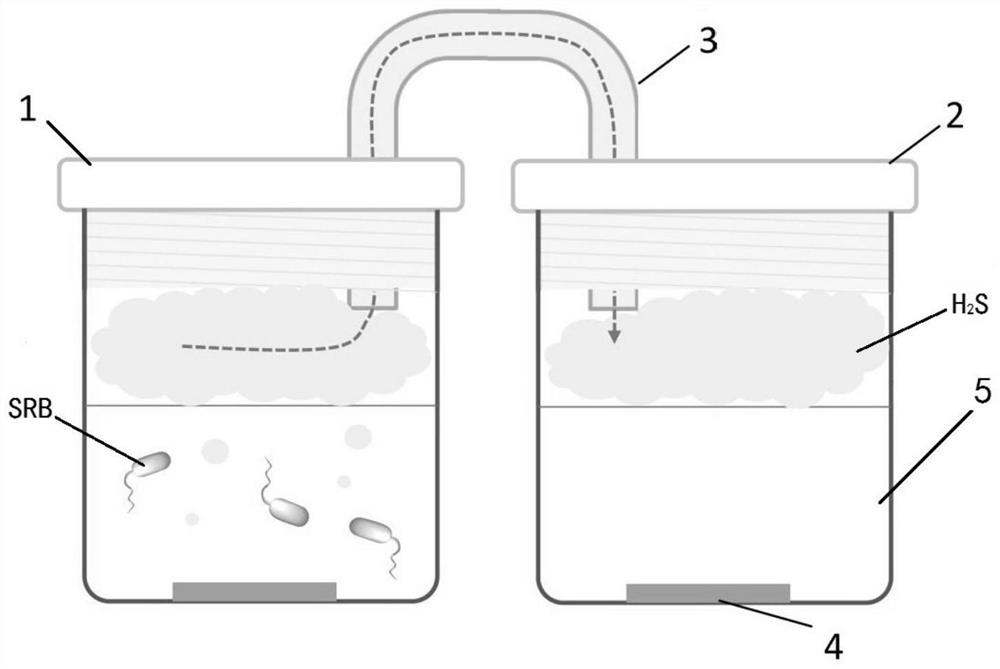

[0032] In the study of microbial (SRB) corrosion of metals, such as figure 2 As shown, metal samples 4 are placed in the main chamber 1 and the sub-chamber 2, the main chamber 1 uses the culture medium inoculated with SRB as the corrosion medium 5, and the SRB corrosion of the metal occurs, and the sub-chamber 2 only Add the same corrosion medium 5 without...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com