Test piece for realizing biaxial stress state through uniaxial loading of spherical working section

A biaxial stress, working section technology, applied in the direction of applying stable tension/pressure to test the strength of materials, measuring devices, instruments, etc. Initial shape, reduced test difficulty and cost, small residual deformation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be further described in detail below in conjunction with the accompanying drawings.

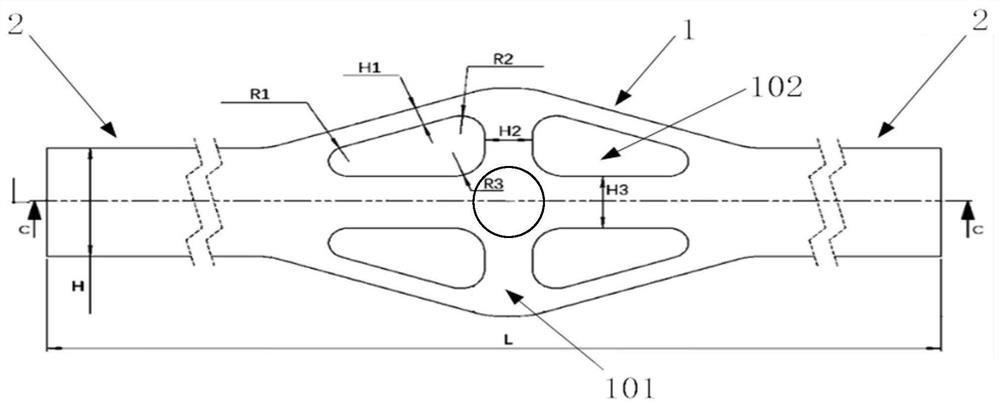

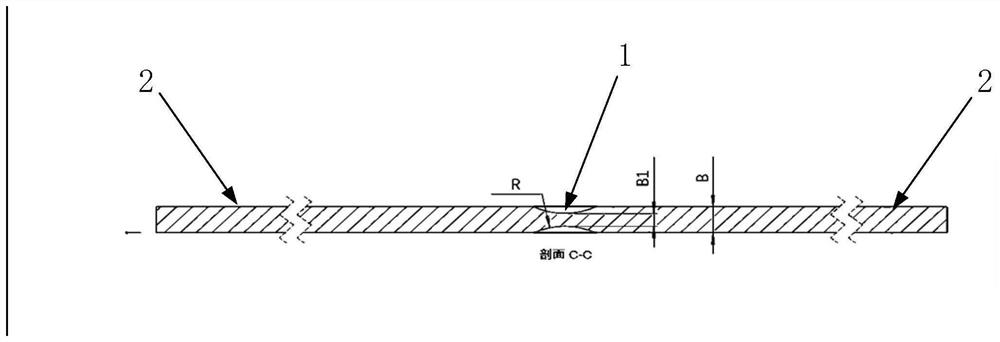

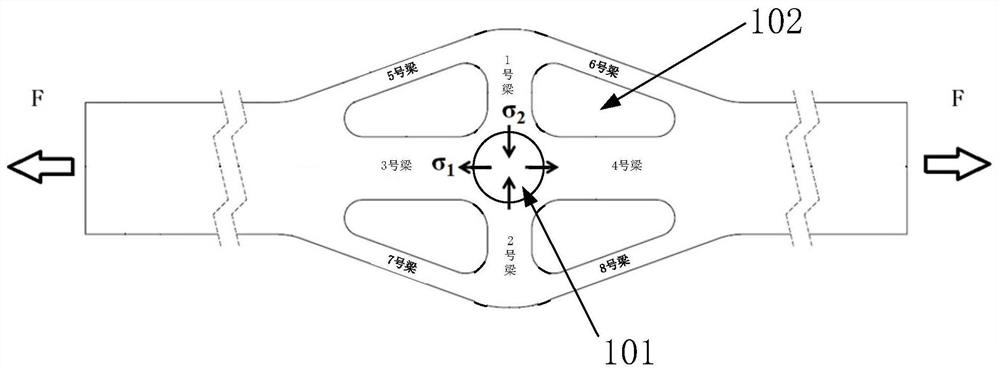

[0024] The uniaxial loading of the spherical working section of the present invention realizes the biaxial stress state. The test piece has a plate-like structure as a whole, a working section 1 with a rhombus structure in the middle, and clamping sections 2 with a rectangular structure on the left and right sides, and the working section 1 with a diamond structure. Both sides of the two diagonals are partially symmetrical. Such as figure 1 , figure 2 shown.

[0025] The ends of the clamping section 2 of the rectangular structure on both sides are respectively connected to the positions of the two opposite angles A and B in the working section 1 of the rhombus structure, and the middle bisector of the clamping section 2 in the left and right directions of the rectangular structure is connected with the clamping The diagonals of angle A and angle B are col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com