High-efficiency, long-life, low-coking and low-blocking regenerator

A regenerator and long-life technology, applied in the field of regenerators, can solve problems such as blocked channels, soot blockage in the flue gas inlet area, and low efficiency, so as to increase service life, extend the cycle of replacing heat storage balls, and reduce broken The effect of crack probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

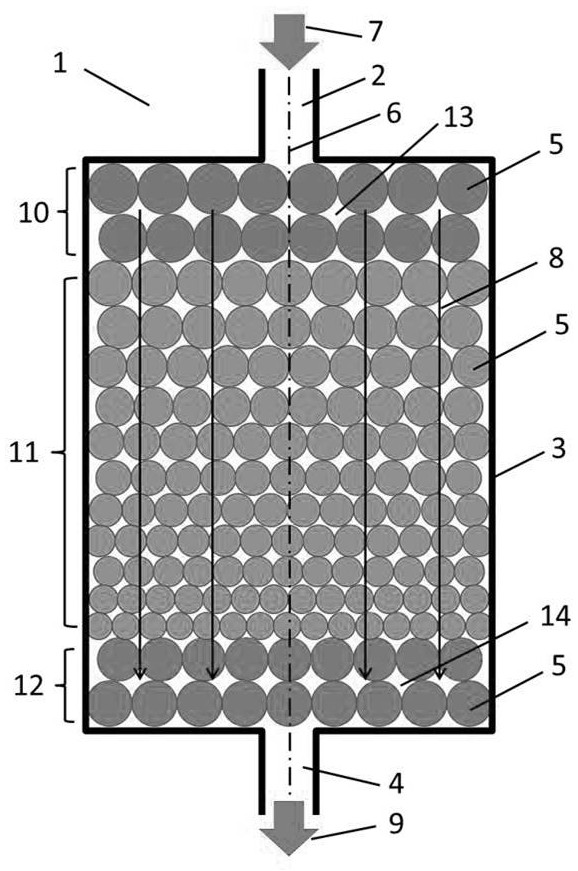

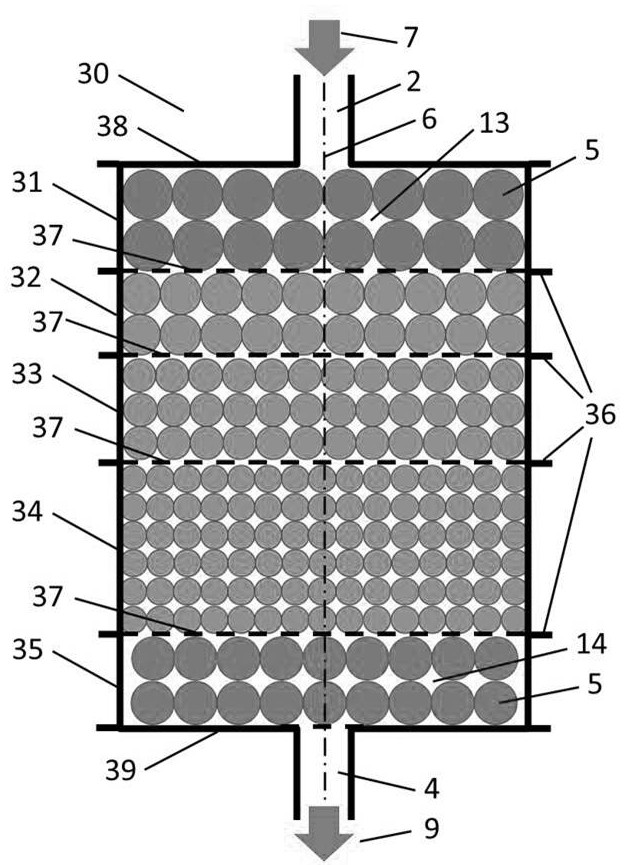

[0044] see Figure 1-7 , the present invention provides the following technical solutions: a high-efficiency, long-life, low-coking and low-blocking regenerator, including flue gas inlet pipe 2, regenerator wall 3 and flue gas outlet pipe 4 arranged in the same direction, wherein the regenerator wall forms The 2 device contains a large number of heat storage balls 5, the smoke inlet area 10 and the smoke outlet area 12 adopt large particle size heat storage balls, and the particle size of the heat storage balls gradually decreases along the smoke flow direction 8 in the middle section 11 of the heat storage chamber. In this embodiment, it is convenient to absorb and store heat.

[0045] Specifically, the flue gas inlet pipe 2 is connected to the combustion chamber and placed parallel to the central axis 6 of the regenerator.

[0046] Specifically, the flue gas outlet pipe 4 communicates with the atmosphere and is placed parallel 6 to the central axis of the regenerator.

[0...

Embodiment 2

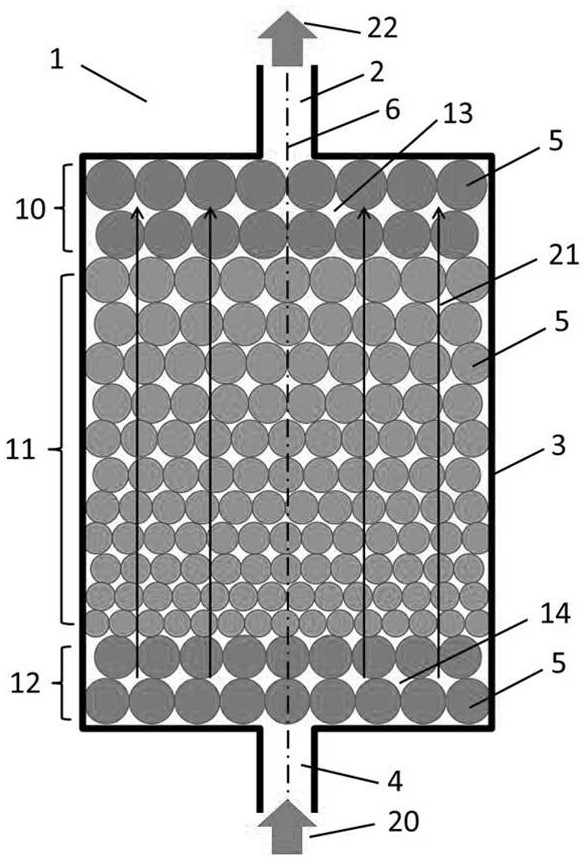

[0061] see Figure 1-7 , the present invention provides the following technical solutions: a high-efficiency, long-life, low-coking and low-blocking regenerator, including flue gas inlet pipe 2, regenerator wall 3 and flue gas outlet pipe 4 arranged in the same direction, wherein the regenerator wall forms The container contains a large number of heat storage balls 5, and the smoke inlet area 10 and the smoke outlet area 12 adopt large particle diameter heat storage balls. In the middle section 11 of the heat storage chamber, the particle size of the heat storage balls gradually decreases along the flow direction 8 of the smoke. In an embodiment, it is convenient to absorb and store heat.

[0062] Specifically, the flue gas inlet pipe 2 is connected to the combustion chamber and placed parallel to the central axis 6 of the regenerator.

[0063] Specifically, the flue gas outlet pipe 4 communicates with the atmosphere and is placed parallel 6 to the central axis of the regener...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com