Switchable rapid interval barring gear device

A turning device and fast technology, applied in the direction of fluid pressure actuators, engine components, machines/engines, etc., can solve problems such as shrinking, sealing structure failure, and accelerated aging of sealing rings

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] Hydraulic cranking method

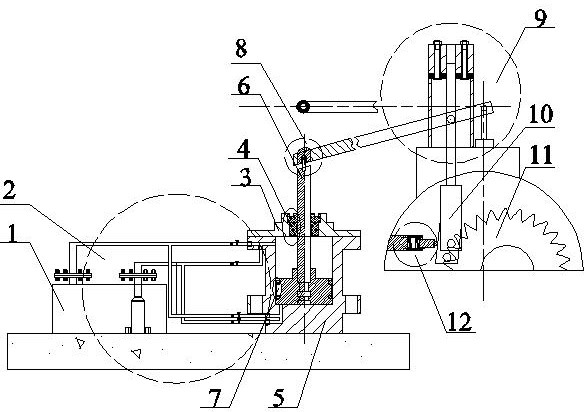

[0032] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 A switchable fast intermittent cranking device is shown, including: fuel tank 1, fast control oil circuit system 2, hydraulic cylinder cover 3, decompression and dust-proof sealing assembly 4, hydraulic cylinder body 5, piston rod 6, piston Sealing assembly 7, detachable connecting piece 8, transmission rod assembly 9, barring hook 10, barring ratchet 11, hook angle self-adjusting mechanism 12.

[0033] The oil tank 1 is connected with the rapid control oil circuit system 2, the oil tank 1 supplies oil for the rapid control oil circuit system 2, and the return oil generated by the rapid control oil circuit system 2 is returned to the Fuel tank 1, the other side of the rapid control oil circuit system 2 is connected to the hydraulic cylinder block 5; the upper end of the hydraulic cylinder block 5 is provided with a hydraulic cylinder cover 3, ...

Embodiment 2

[0038] Manual cranking method

[0039] When the hydraulic cranking system fails, it needs to be converted to manual cranking. The manual cranking mode is different from the hydraulic cranking mode except that the power source is different. The connection mode between the mechanisms 12 is exactly the same as the hydraulic cranking mode, and will not be repeated in this embodiment; the difference is that when the hydraulic cranking system fails, only the detachable screw 812 needs to be removed to realize the pressure rod 911 Disengagement with the piston rod 6 is realized by manual cranking by manually shaking the depression bar 911 up and down.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com