Circular concrete formwork capable of being assembled and reinforcement method

A technology of concrete formwork and formwork, which is applied in the direction of formwork/formwork/work frame, connection of formwork/formwork/work frame, and on-site preparation of building components, etc. Problems such as the thickness of cylindrical steel formwork

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

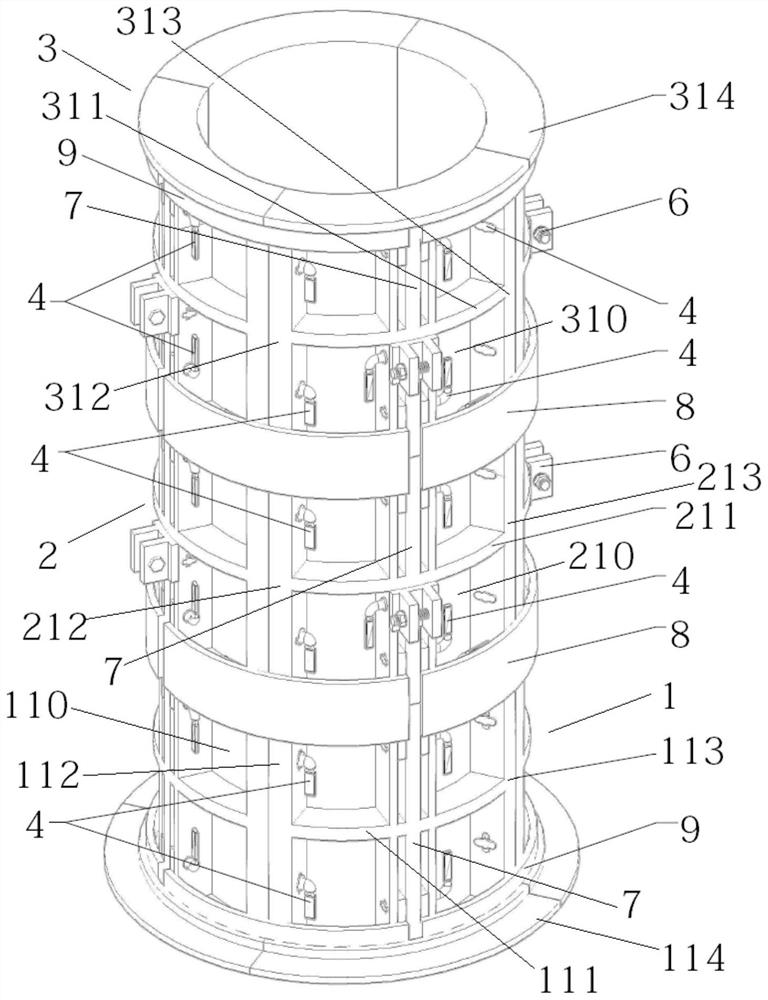

[0048] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 7 As shown, a circular concrete form that can be assembled includes a base 1, a standard segment 2, an end 3 and a handle 4, the standard segment 2 is arranged on the base 1, and the end 3 is arranged on the standard segment 2 , the outer wall of the terminal 3 is provided with a transverse rib a311, the outer wall of the standard segment 2 is provided with a transverse rib b211, the outer wall of the base 1 is provided with a transverse rib c111, the transverse rib a311, the transverse rib b211 and the transverse rib c111 are all A plurality of notches 5 are provided, and one end of a part of the handle 4 extends through the notch 5 on the transverse rib a311 into the notch 5 on the transverse rib b211, and rotates the preset angle so that the end 3 and the standard segment 2 Detachable connection; one end of part of the handle 4 extends into the notch 5 on the transverse rib c111 through the notch 5 on ...

Embodiment 2

[0050] Such as figure 2 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1, which is specifically as follows:

[0051] The terminal 3 includes a plurality of templates a310, and the plurality of templates a310 are connected end to end to form a ring. The number of templates a310 can be two, three, four, five, etc., and in the view given by the present invention, The number of templates a310 is four; each template a310 is provided with longitudinal ribs a312 and longitudinal ribs b313, and both longitudinal ribs a312 and longitudinal ribs b313 are provided with notches 5, and one end of some handles 4 passes through any two adjacent The notch 5 on the longitudinal rib a312 of one template a310 in the template a310 extends into the notch 5 on the longitudinal rib b313 of the other template a310, and the two templates a310 are detachably connected by rotating a preset angle.

Embodiment 3

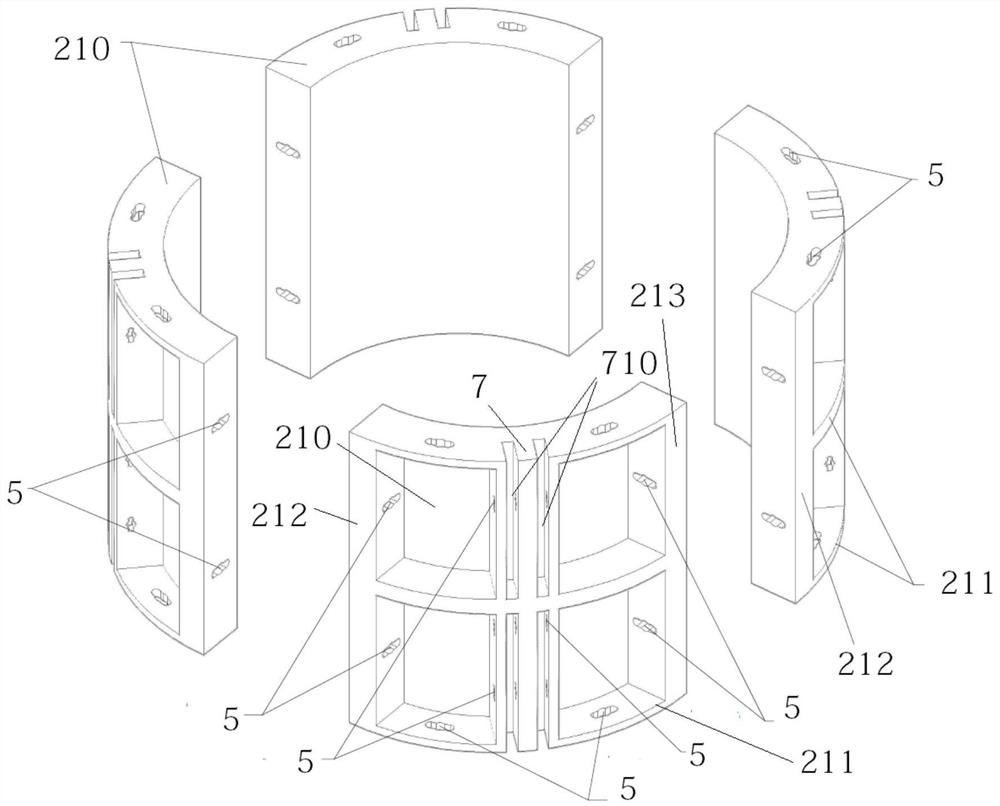

[0053] Such as image 3 As shown, the present embodiment is a further optimization carried out on the basis of embodiment 1, which is specifically as follows:

[0054] The standard segment 2 includes a plurality of templates b210, which are connected end to end in turn to form a ring, and the number of templates b210 can be two, three, four, five, etc., and in the view provided by the present invention , the number of templates b210 is four; each template b210 is provided with longitudinal ribs c212 and longitudinal ribs d213, both longitudinal ribs c212 and longitudinal ribs d213 are provided with notches 5, and one end of a part of the handle 4 passes through any adjacent two The notch 5 on the longitudinal rib c212 of one template b210 of the block templates b210 extends into the notch 5 on the longitudinal rib d213 of the other template b210, and the two templates b210 are detachably connected by rotating a preset angle .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com