Modular fabricated concrete self-insulation wallboard

A prefabricated, concrete technology, applied in thermal insulation, walls, structural elements, etc., can solve the problems of low production efficiency, inability to bear the load of outer blades, and difficulty in reducing production costs, and achieve high production efficiency, strong integrity, and tightness. Good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] In order to deepen the understanding of the present invention, the present invention will be further described below in conjunction with the embodiments and accompanying drawings. The embodiments are only used to explain the present invention and do not constitute a limitation to the protection scope of the present invention.

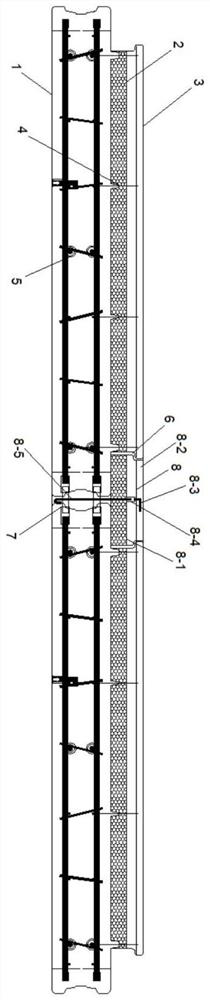

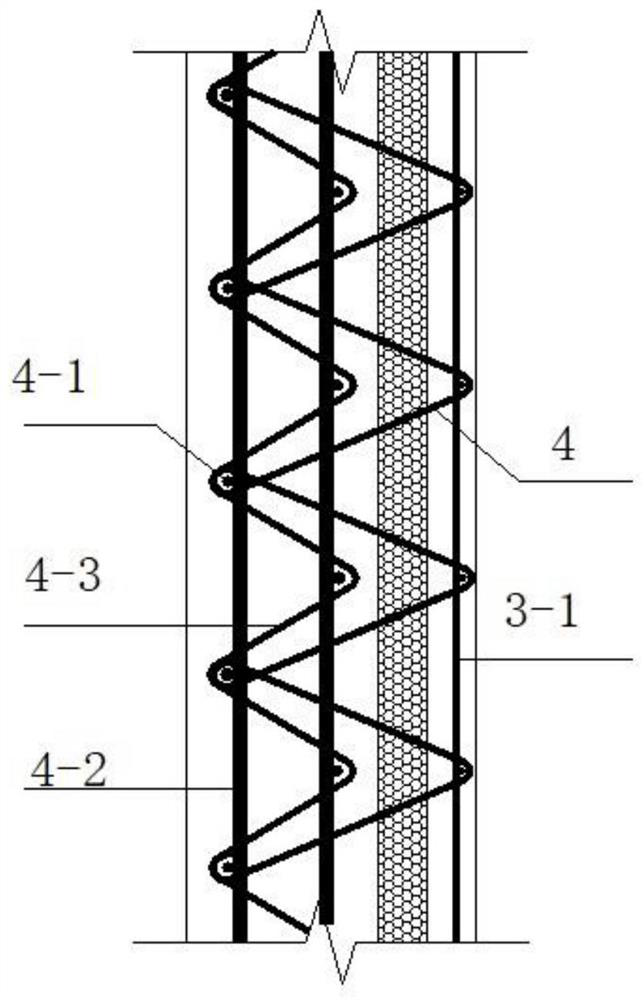

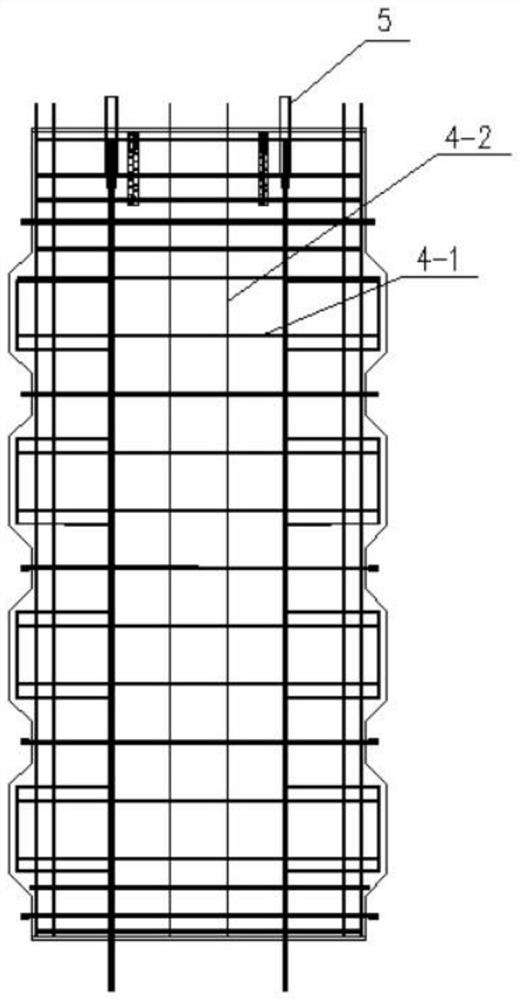

[0021] Such as Figure 1-Figure 4 It shows a specific embodiment of a modular assembled concrete self-insulating wall panel: it includes a main wall layer 1, an insulating core layer 2 and an outer leaf protection layer 3, and the main wall layer 1 and the outer leaf protection layer 3 The V-shaped tie bars 4 are connected between them, and the V-shaped tie bars 4 are composed of main wall horizontal bars 4-1, main wall longitudinal bars 4-2 and main wall truss bars 4-3. The main wall horizontal bar 4-1 and the main wall longitudinal bar 4-2 all penetrate the ring hook point of the main wall truss bar 4-3, and are welded with it to form a V-shape...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com