Method for adjusting pH value of printing and dyeing washing machine and conveying system used for same

The technology of a conveying system and a water washing machine is applied in the field of a method and the conveying system used in the method, which can solve problems such as troublesome operation and unstable pH value of fabrics, and achieve the effects of easy operation, bright color and reduced greenhouse effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

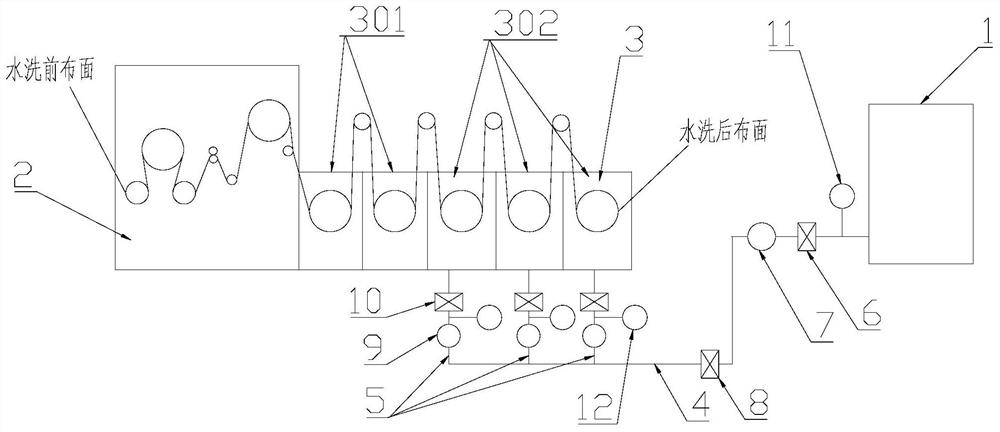

[0032] Such as figure 1 As shown, the present invention provides a delivery system for adjusting the pH value of a printing and dyeing washing machine, including a liquid storage tank 1 and a washing machine 2, and the washing machine 2 includes five washing tanks 3;

[0033] The washing tank 3 is divided into a clear water area 301 and an adjustment area 302, the number of the clear water area 301 is 2, and the number of the adjustment area 302 is 3;

[0034] The liquid storage tank 1 is connected to the conditioning area 302 of the water washing tank 3 through a pipeline, and the pipeline includes a main pipeline 4 and a branch pipeline 5;

[0035] Valve B6, flowmeter A7 and valve A8 are arranged in sequence on the main pipeline 4 to control the total flow of liquid carbon dioxide entering the branch pipeline 5; After the carbon dioxide inside is treated, it can be opened to improve the controllability and accuracy of the flow of liquid carbon dioxide, and at the same time,...

Embodiment 2

[0042] Fabric surface: pure cotton thin fabric, fabric weave specification is C100×80 230×200 fabric, fabric weight 120g / m 2 ;Cloth color: emerald blue;

[0043] Cloth surface treatment process: After the above-mentioned cloth surface is singed, desized, bleached, mercerized, whitened and dyed, the pH value of the cloth surface is measured to be 8.3-8.6;

[0044] Conveyor system setup:

[0045] Such as figure 1 As shown, open valve B6, flow meter A7 and valve A8, control the delivery pressure to 0.2MPa, and open the flow meter B9 and valve C10 above the second branch pipeline 5 and the third branch pipeline 5 counted from the left in the adjustment area 302, and control The amount of liquid carbon dioxide that enters the second branch pipeline 5 and the third branch pipeline 5; after the liquid carbon dioxide enters the conditioning area 302 and counts the second washing tank and the third washing tank from the left, wait for 30 minutes, and the cloth begins to enter the condi...

Embodiment 3

[0052] Cloth surface: polyester cotton Thick fabric: T / C 20×16 100×56 fabric, weight 210g / m 2 ;Cloth color: rose red;

[0053] Cloth surface treatment process: After the above-mentioned cloth surface is singed, desized, bleached, mercerized and dyed, the pH value of the cloth surface is measured to be 8.3-8.6;

[0054] Conveyor system setup:

[0055] Such as figure 1 As shown, open valve B6, flowmeter A7 and valve A8, control the delivery pressure to 0.4MPa, and open the flowmeters above the first branch pipeline 5, the second branch pipeline 5 and the third branch pipeline 5 in the regulation area 302 from the left B9 and valve C10 control the amount of liquid carbon dioxide entering the first branch pipeline 5, the second branch pipeline 5 and the third branch pipeline 5; the liquid carbon dioxide enters the adjustment area 302 and counts the first washing tank, the second washing tank and the second washing tank from the left After the three washing tanks, wait for 30 mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com