Moulding foamed products, its forming method and loudspeaker diaphragm constituted therewith

A foamed product and speaker technology, applied in the field of molded foamed products, can solve the problem of high cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Preferred embodiments of the present invention are explained below with reference to the accompanying drawings.

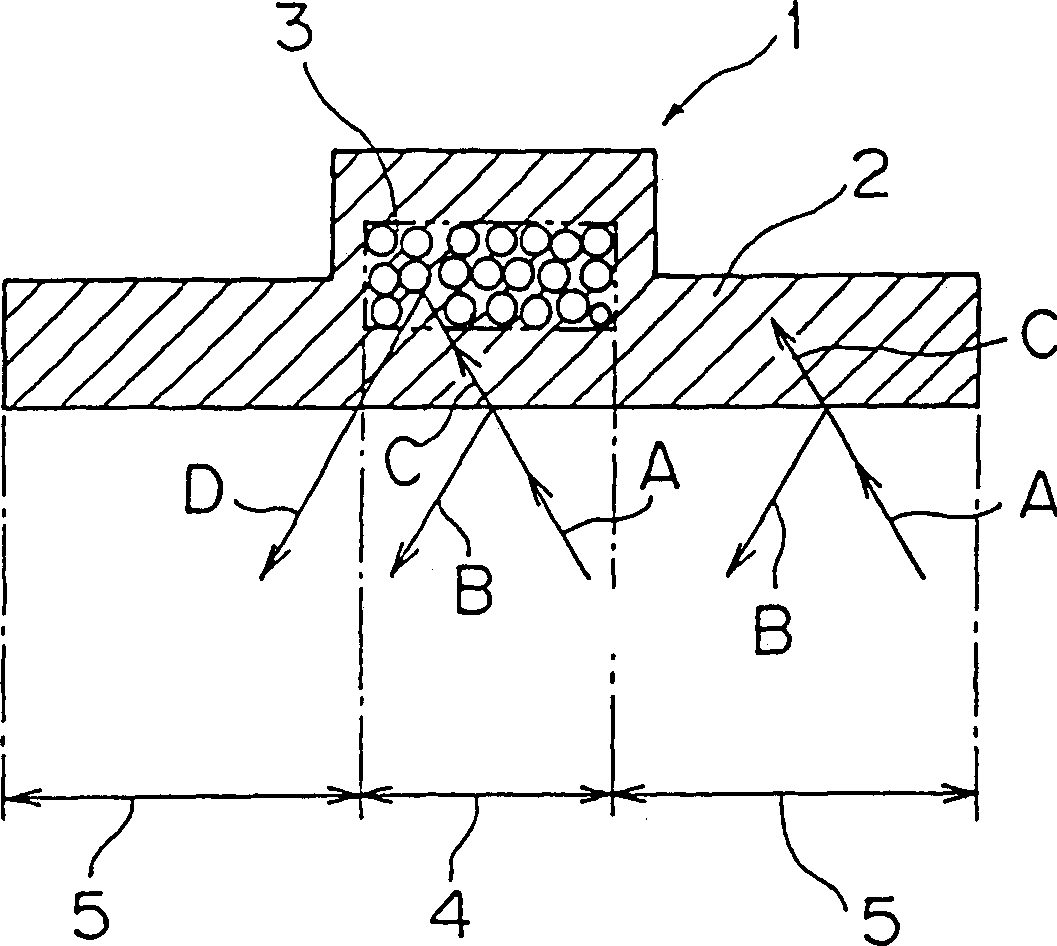

[0034] figure 1 is a cross-sectional view of a molded foamed article according to the present invention, wherein a molded foamed article 1 is formed with a foamed region 4 of a three-layer structure consisting of a foamed inner layer 3 and a non-foamed outer layer (skin layer 2) and A non-foaming region 5 of a single-layer structure composed of a non-foaming layer (skin layer 2 ) is formed.

[0035] Such as figure 1 As shown, when light A irradiates the molded foam product 1 , part of the light A is reflected on the surface as reflected light B, and the rest of the light A becomes transmitted light C and penetrates into the molded foam product 1 .

[0036] In the non-foaming region 5, the transmitted light C continues to pass through the molded foamed article 1, as a result of which the color tone of the reflected light B is given in the non-foaming region...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com