Powertrain mount structure of vehicle

A powertrain and vehicle technology, applied in the direction of power devices, vehicle components, transmission parts, etc., can solve the problem of lowering the rigidity of the vehicle body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

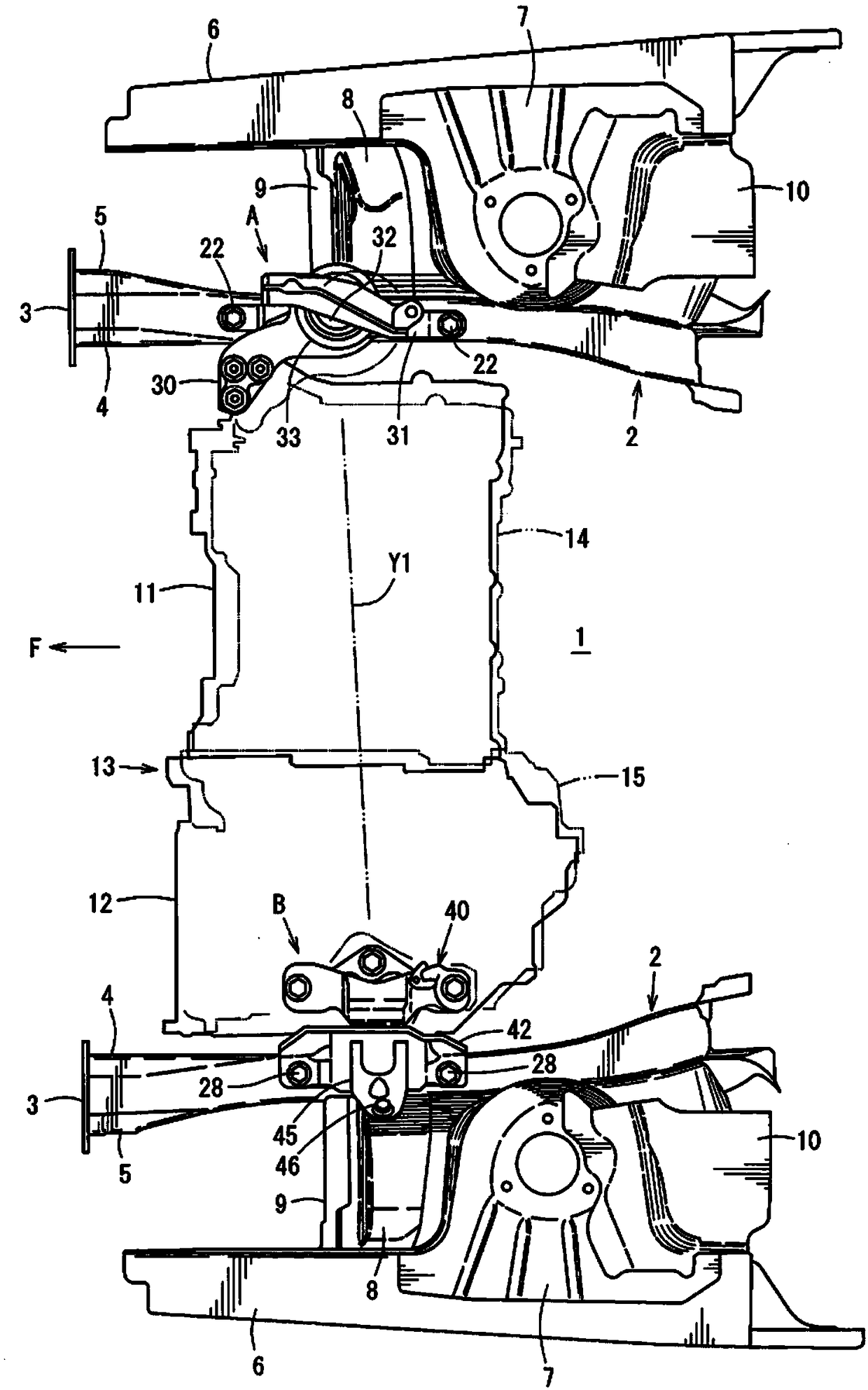

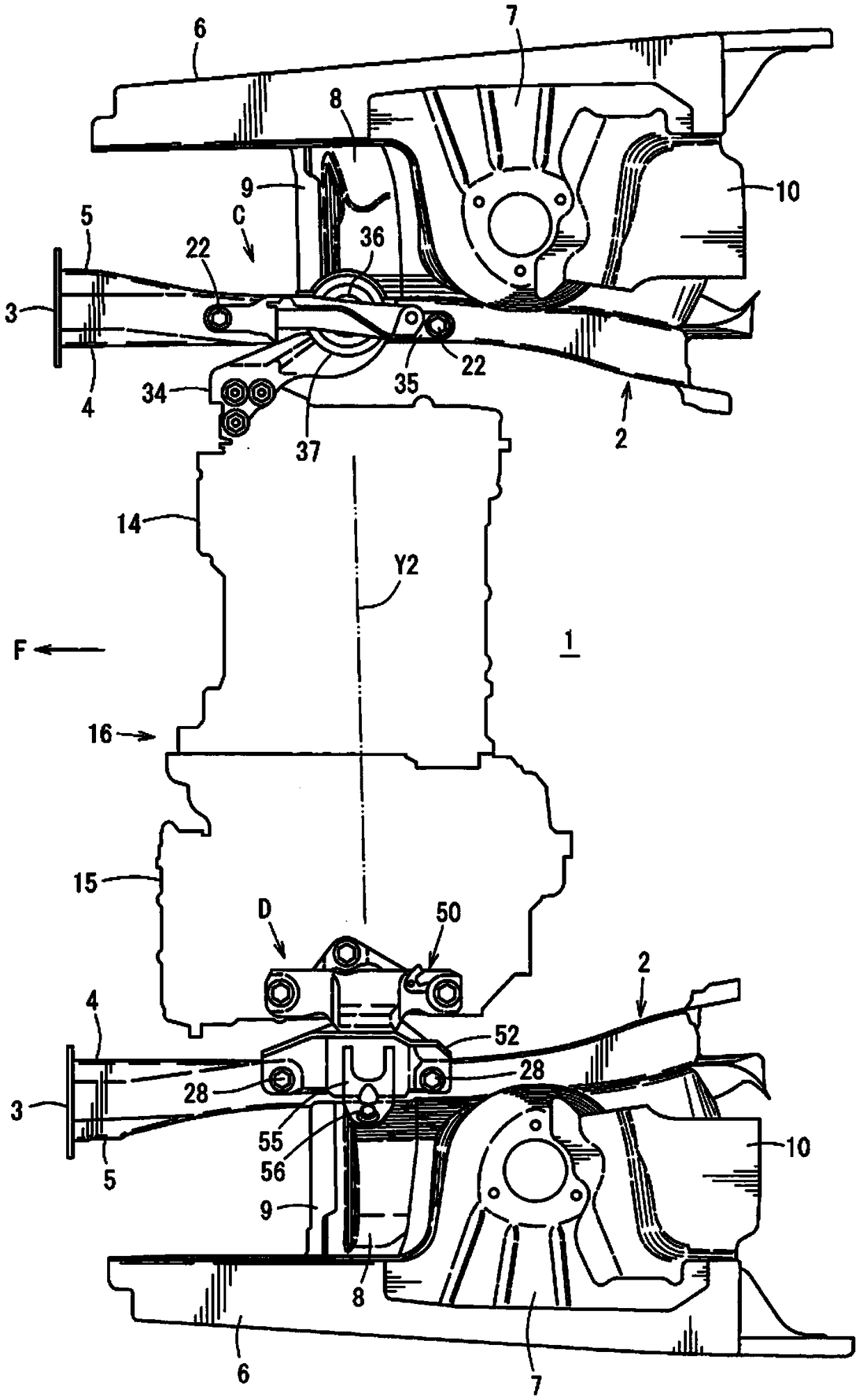

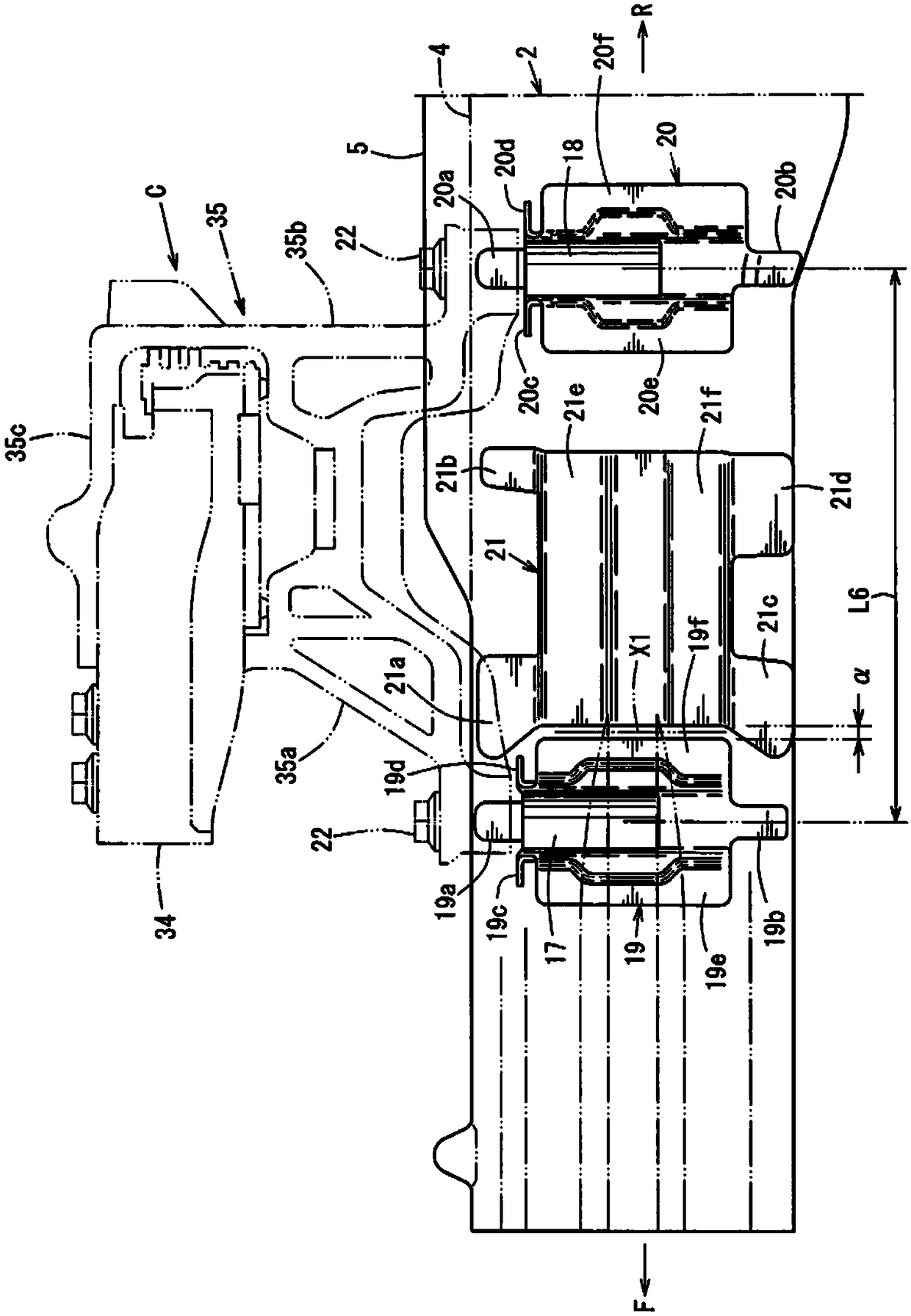

[0044] In order to adjust the position of the elastic roller of the powertrain without reducing the rigidity of the vehicle body, the powertrain assembly structure of the vehicle of the present invention has: left and right front side frames along the front-rear direction of the vehicle on the left and right sides of the engine compartment Extension: the first assembly supporting part, including the first assembly pad and the first assembly bracket holding the first assembly pad, the first assembly bracket is opposite to one of the front side frames of the left and right front frames A plurality of mounting points are provided at intervals in the front and rear, and the powertrain is mounted to the one front side frame through the first mounting bracket via the first mounting rubber pad; and the second mounting support part includes a second mounting A rubber pad and a second mounting bracket holding the second mounting rubber pad. The second mounting bracket is provided with a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com