Composite non-bonding flexible pipe, preparation method and application

A reinforced composite material, non-bonding technology, applied in the field of flexible pipes, can solve the problems such as the gap control of the spirally wound strip of the bearing layer, and achieve the effect of improving the bearing capacity of internal pressure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0056] In the second aspect, the preparation method of the above-mentioned non-adhesive composite flexible pipe, the specific steps of the preparation method are:

[0057] The hot melt adhesive layer and the first elastic material layer are coated on the outer sidewall of the inner liner by means of a multi-layer co-extruded inner tube;

[0058] Wrapping the compression-resistant layer on the outer surface of the first elastic material layer by means of interference fit;

[0059] A second elastic material layer is arranged on the outer surface of the pressure-resistant layer by heating and extruding;

[0060] Then repeat the setting of the elastic material layer and the compression layer;

[0061] wrapping the tensile layer around the outer surface of the compression layer;

[0062] The outer protection layer is arranged on the outside of the tensile layer by extrusion molding.

[0063] In the third aspect, the above-mentioned non-adhesive flexible pipe of composite materia...

Embodiment 1

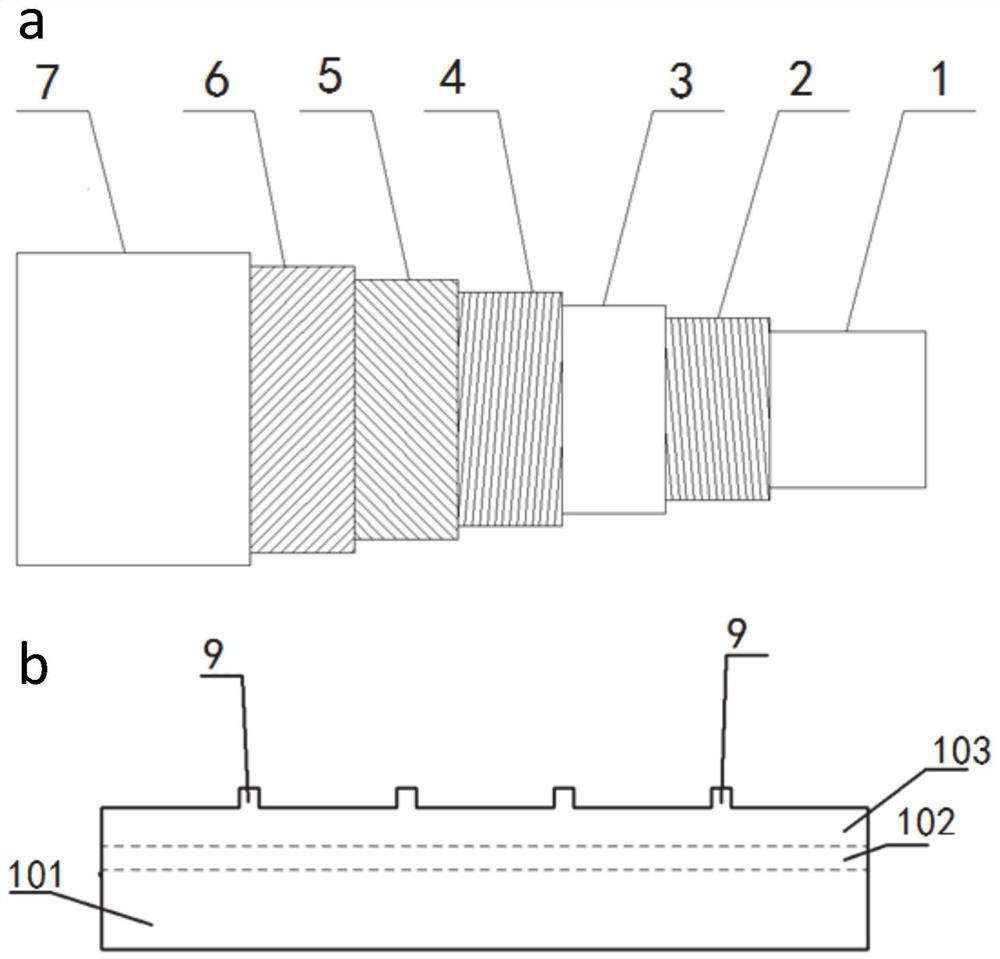

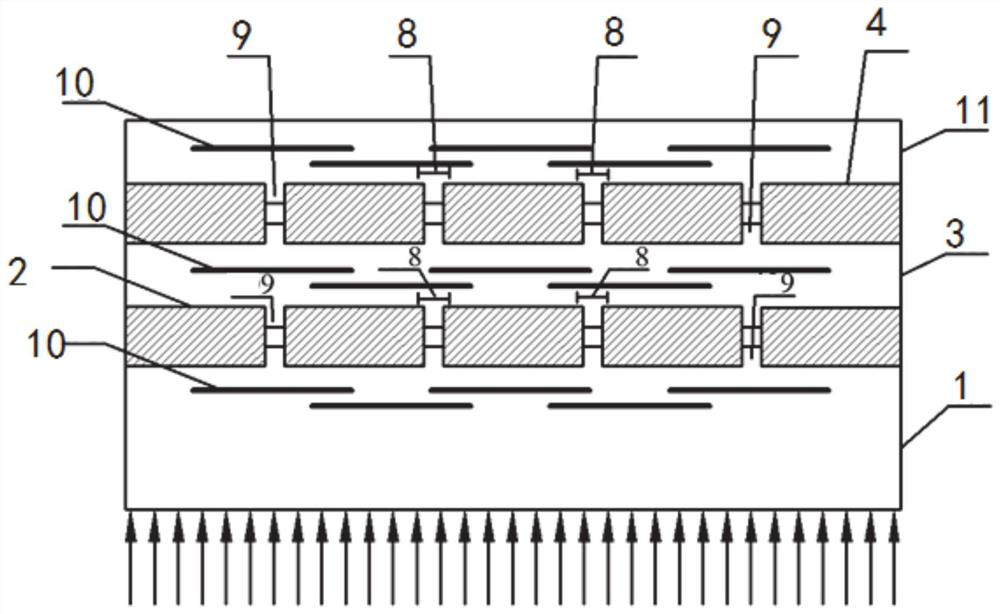

[0066] Such as figure 1 As shown in a, the flexible pipe from inside to outside is the lining pipe layer 1, the first compression layer 2, the second elastic material layer 3, the second compression layer 4, the first tensile layer 5, and the second anti-tension layer. Pull layer 6, outer protection layer 7. Such as figure 1 As shown in b, the inner liner layer includes an inner liner 101 , a hot melt adhesive layer 102 , and a first elastic material layer 103 from inside to outside.

[0067] Such as figure 1 As shown in b, the first elastic material layer 103 is used as a gap control layer, and the first elastic material layer 103, the hot melt adhesive layer 102, and the inner liner 101 are combined by hot extrusion. The first compression layer 2 is spirally wound on the outer surface of the first elastic material layer 103, the second elastic material layer 3 is arranged on the first compression layer 2 by heating extrusion molding, and then the second compression layer ...

Embodiment 2

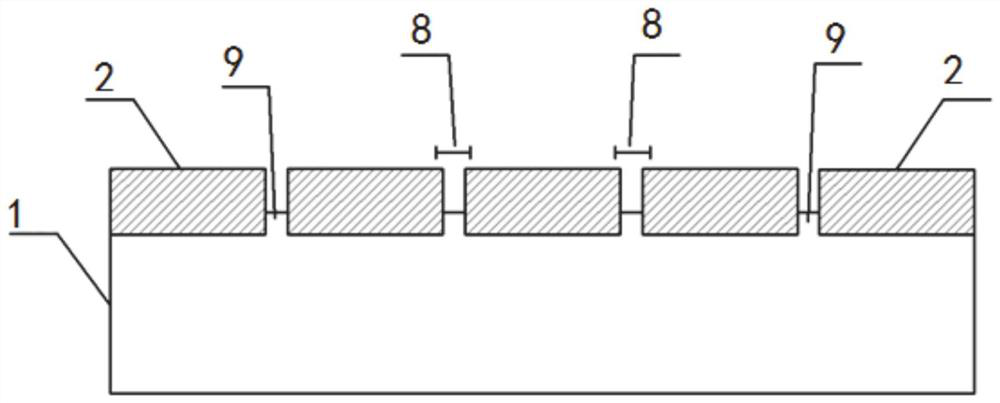

[0071] Such as figure 2 As shown, compared to Example 1, the structure and distribution of the flexible tube is different. The flexible pipe is provided with an inner liner layer 1 and a first compression layer 2, and a tensile layer and an outer protective layer are arranged on the outside of the first compression layer 2. The inner liner layer includes an inner liner, a hot melt adhesive layer and a first elastic material layer from inside to outside.

[0072] The first elastic material layer is used as the gap control layer. The combination of the first elastic material layer, the inner liner pipe and the hot melt adhesive layer is the same as that in Example 1. The position of the first elastic material layer relative to the gap between the first compression layer 2 The protrusions enter the gaps 8 of the pressure-resistant layer to form fillers 9 .

[0073] The elastic material layer is made of propylene-based elastomer. The compression layer is a helically wound cont...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Winding angle | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Winding angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com