Combined tool for online milling of steel rail

A technology of combining cutters and rails, which is applied in the direction of milling cutters, manufacturing tools, milling machine equipment, etc., can solve the problems of self-excited vibration, low economical use of blades, and cumbersome adjustment process of cutters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

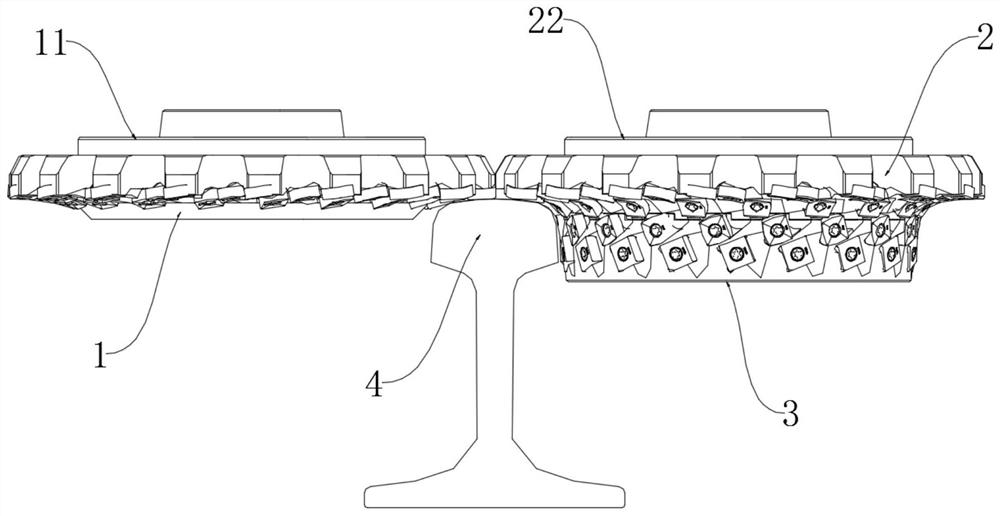

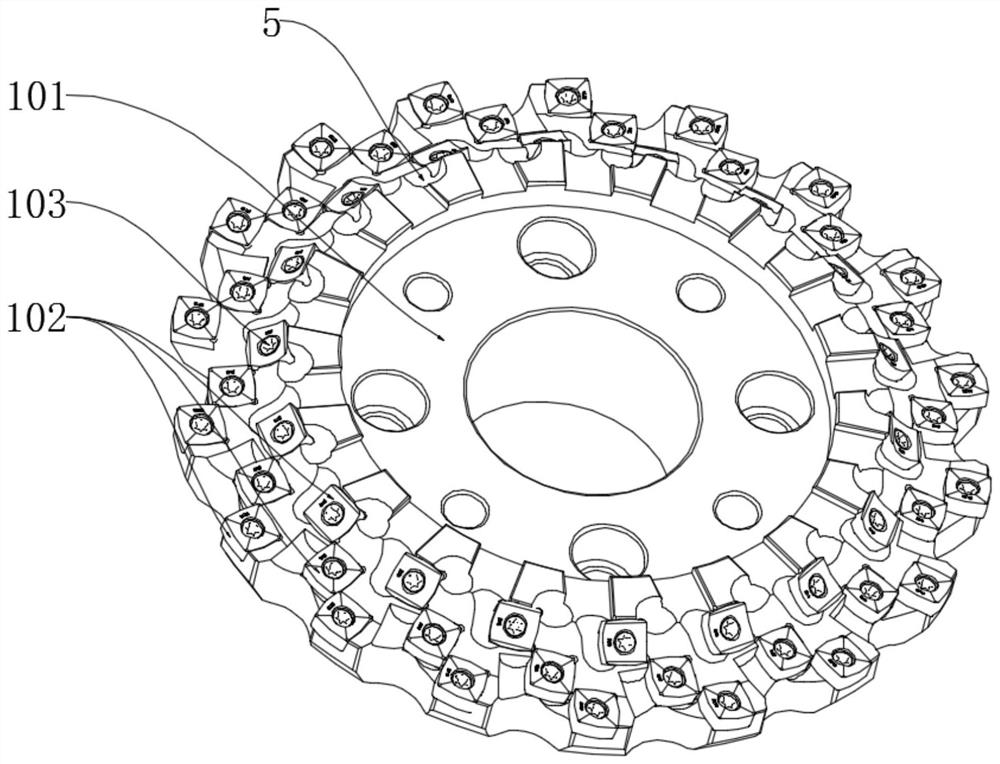

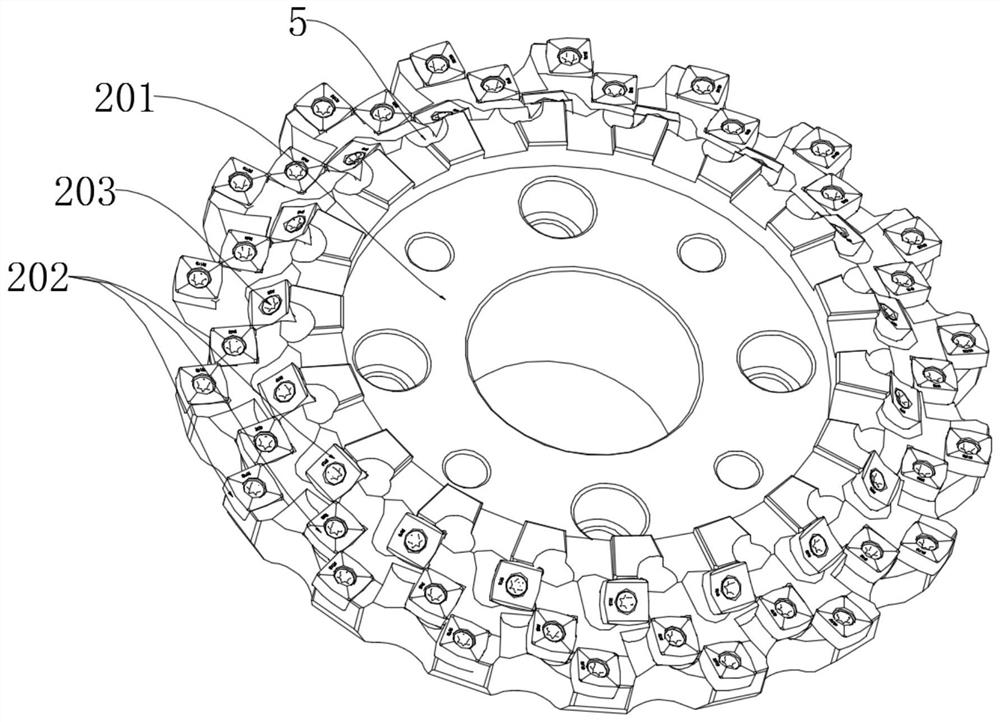

[0078] like Figure 1 to Figure 5 As shown, the embodiment of the present invention provides a combination tool for online milling of rails, including a cutter head assembly, the cutter head assembly is connected to a driving device, and a cutting element is provided on the cutter head Assemblies, in order to realize the forming processing of different areas on both sides of the center line of the top surface of the rail 4.

[0079] like Figure 1 to Figure 5 As shown, the cutterhead assembly includes at least two cutterheads, wherein the cutterhead assembly includes a first main cutterhead 1 and a second main cutterhead 2, and the first main cutterhead 1 and the second main cutterhead 2 have the same structure , and symmetrical to both sides of the centerline of the top surface of the rail 4 rails.

[0080] In the embodiment of the present invention, the cutting element is a cutting blade, especially a cemented carbide milling cutter. After the cutter head assembly is insta...

Embodiment 2

[0093] Such as Image 6 with Figure 7 As shown, the embodiment of the present invention provides a combined tool for rail online milling, the same as embodiment 1, the difference is that: the first cutter base 101 and the second cutter base 201 are respectively the same as the The above-mentioned third cutter head base 301 is integrally formed, the structure is more compact and the connection strength can be improved, making the structure stronger.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter size | aaaaa | aaaaa |

| Diameter size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com