In-situ energy controlled selective laser melting device and method

A technology of laser selective melting and energy control, which is applied in the field of additive manufacturing, can solve the problems of single laser energy mode and limited amplitude, and achieve the effect of improving forming quality, reducing internal stress and improving density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

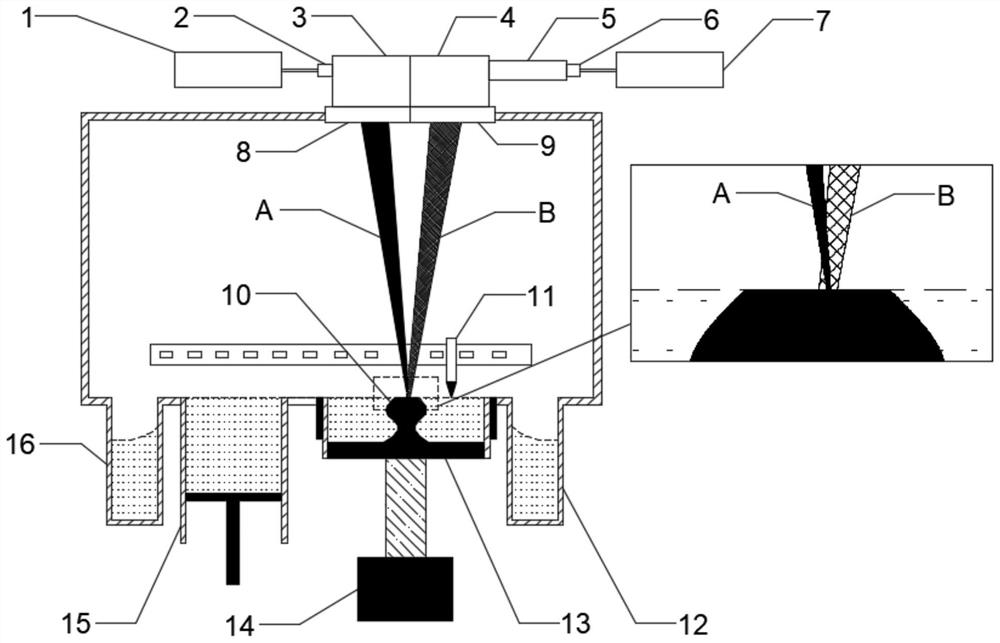

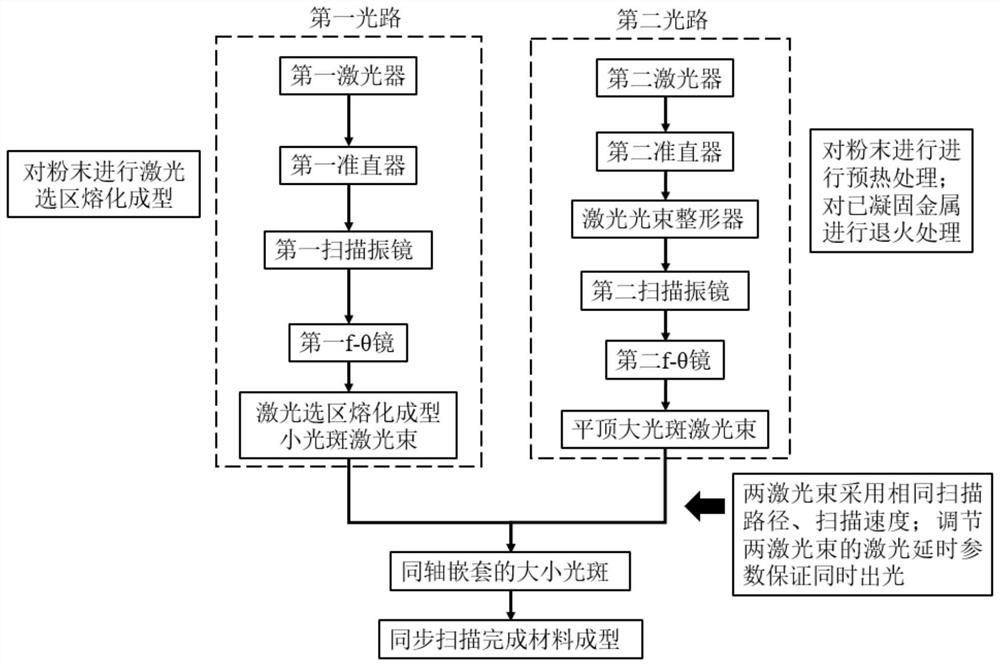

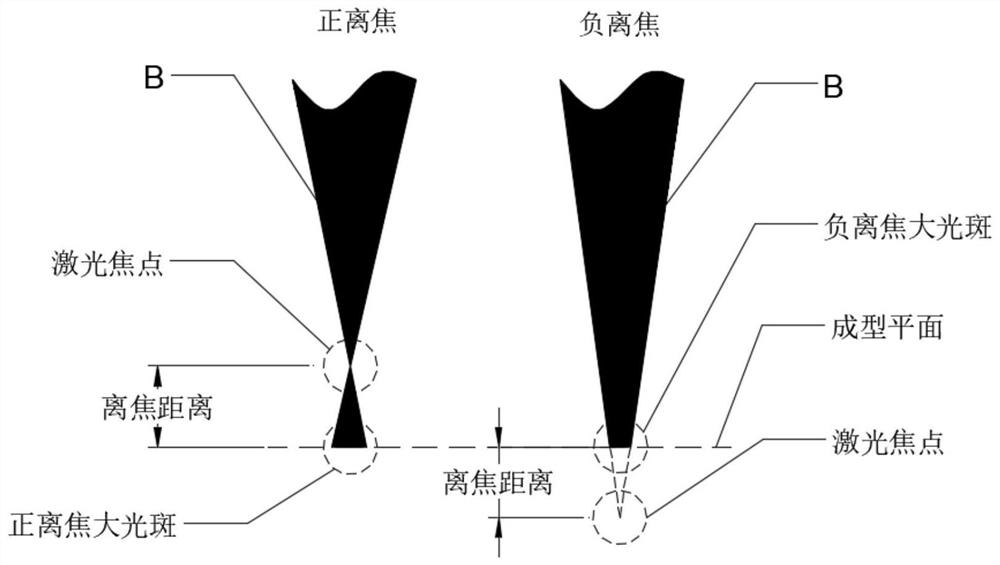

[0039] like figure 1 As shown, this embodiment is an in-situ energy-controlled laser selective melting device, including a laser selective melting forming small spot light path device, a newly added flat-top large spot light path device and a laser selective melting forming device. The laser selective melting forming is small The light spot light path device and the newly added flat-top large spot light path device are set on the laser selective melting molding equipment; in this embodiment, a new flat-top large spot for synchronous scanning is added to provide energy below the powder melting point threshold for powder preheating / The solidification rate is controlled, and the formed metal is annealed to reduce the temperature gradient and reduce the internal stress of the forming, thereby reducing the deformation, cracking and other behaviors caused by the stress.

[0040] Further, the small-spot optical path device for laser selective melting molding includes a first laser 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com