Electromagnetically driven electro-hydraulic pipe forming device and method

An electromagnetic drive, pipe fitting technology, applied in the field of metal forming and manufacturing, can solve the problems of thinning and cracking of workpieces

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

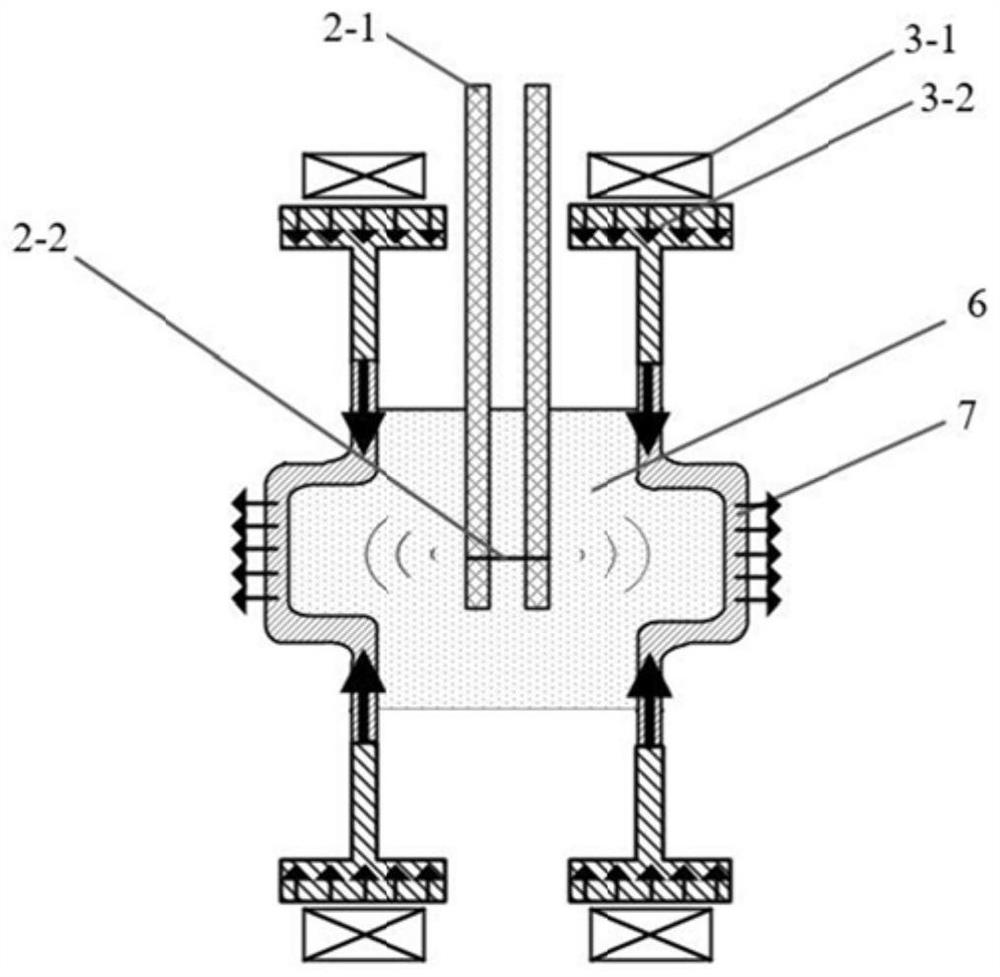

[0037] Such as image 3 As shown, it is a structural schematic diagram of the electromagnetic drive-electro-hydraulic pipe fitting forming device provided by Embodiment 1 of the present invention. The device includes: a power supply module, a forming module, a booster module, a forming mold, and a fixing unit.

[0038] Among them, the power supply module includes a power supply 1-1 for boosting and a power supply 1-2 for forming; the forming module includes a metal electrode 2-1 and a metal wire 2-2; the boosting module includes a boosting coil 3-1 and a driving board 3-2. 2. The forming mold includes a mold cavity 4-1, an air vent 4-2, and a sealing plug 4-3; the fixing unit includes a fixing frame 5-1 and a telescopic gasket ring 5-2.

[0039] Specifically, the power module includes a power supply 1-1 for boosting and a power supply 1-2 for forming. The power supply 1-2 for forming is used to provide pulse current for the metal wire 2-2; the metal wire 2-2 is located in the...

Embodiment 2

[0063] Such as Figure 5 As shown, the forming die in the second embodiment provided by the present invention is different from the first embodiment; the way of using multiple metal wires is different from the first embodiment; other structures are the same as the first embodiment.

[0064] In this embodiment, the forming mold is corrugated for forming bellows. The bellows is characterized in that there are multiple forming centers in the forming area, and the efficiency of a single metal wire explosion is low; at the same time, it is difficult to adopt multiple Compound forming with secondary axial push.

[0065] This embodiment provides the device and method of the forming embodiment of the electro-hydraulic and electromagnetic combination of the bellows in the state of multiple metal wires.

[0066] Its device and method are basically the same as Embodiment 1, the difference is:

[0067] (1) The number of metal wires 2-2 is the same as the number of mold corrugations, and...

Embodiment 3

[0070] Such as Figure 6 As shown, when only one end of the workpiece to be formed needs to be boosted, a single-end loading axial boosting device can be used; the specific steps are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com