Metal-modified molecular sieve-based diesel oxidation catalyst and preparation and use methods thereof

An oxidation catalyst, molecular sieve-based technology, applied in the direction of metal/metal oxide/metal hydroxide catalyst, molecular sieve catalyst, chemical instruments and methods, etc., can solve the problem of increasing the maintenance of the whole machine, maintenance costs, and damage to the reliability of the DPF carrier And life, additional fuel consumption and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

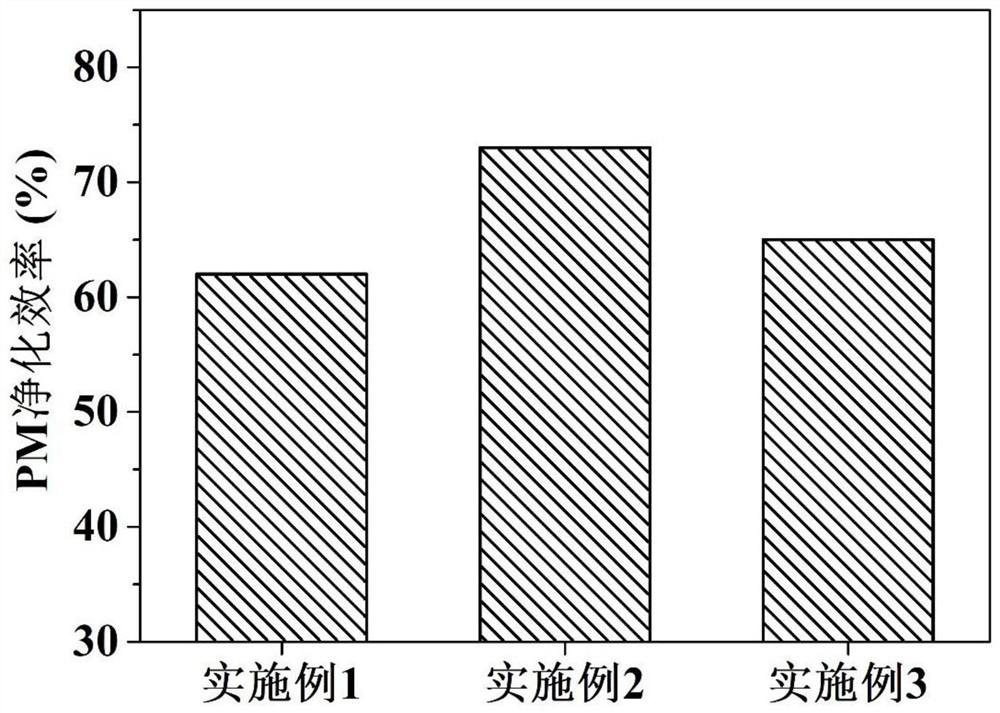

Embodiment 1

[0031] A method for preparing a catalyst for a metal-modified molecular sieve-based diesel engine oxidation catalyst, comprising the following steps:

[0032] (1) Catalyst composition design

[0033] The components with the following mass fractions were designed respectively: V / Mo / K ternary metal modified ZSM-5 molecular sieve and Ag 2 The mass fractions of O are 80%, 20%, respectively, V 2 o 5 、MoO 3 、K 2 The mass fractions of O and ZSM-5 molecular sieves are 5%, 10%, 5%, 80%, respectively, CeO 2 and ZrO 2 The mass fractions are 60%, 40%, respectively, γ-Al 2 o 3 and SiO 2 The mass fraction of the main catalytic active component, the co-catalyst and the coating base material are respectively 30%, 20%, and 50%. The target of the catalytic coating and the carrier The mass percentage ranges are: 22-24%, 76-78%, the sum of the mass fractions of the catalytic coating and the carrier is 100%, and a coating slurry capable of forming 2000g of the catalytic coating is prepare...

Embodiment 2

[0041] A method for preparing a catalyst for a metal-modified molecular sieve-based diesel engine oxidation catalyst, comprising the following steps:

[0042] (1) Catalyst composition design

[0043]The components with the following mass fractions were designed respectively: V / Mo / K ternary metal modified ZSM-5 molecular sieve and Ag 2 The mass fractions of O are 80%, 20%, respectively, V 2 o 5 、MoO 3 、K 2 The mass fractions of O and ZSM-5 molecular sieves are 10%, 20%, 10%, 60%, respectively, CeO 2 and ZrO 2 The mass fractions are 80%, 20%, respectively, γ-Al 2 o 3 and SiO 2 The mass fraction of the main catalytic active component, the co-catalyst and the coating base material are respectively 20%, 10%, and 70%. The target of the catalytic coating and the carrier The mass percentage ranges are: 28-30%, 72-70%, the sum of the mass percentages is 100%, and the planned configuration of the coating slurry can produce 2000g of the catalytic coating.

[0044] (2) Preparati...

Embodiment 3

[0051] A method for preparing a catalyst for a metal-modified molecular sieve-based diesel engine oxidation catalyst, comprising the following steps:

[0052] (1) Catalyst composition design

[0053] The components with the following mass fractions were designed respectively: V / Mo / K ternary metal modified ZSM-5 molecular sieve and Ag 2 The mass fractions of O are 70%, 30%, and V 2 o 5 、MoO 3 、K 2 The mass fractions of O and ZSM-5 molecular sieves are 10%, 10%, 10%, 70%, respectively, CeO 2 and ZrO 2 The mass fractions are 75%, 25%, respectively, γ-Al 2 o 3 and SiO 2 The mass fractions of the catalyst coating and the carrier are respectively 85%, 15%, and the mass fractions of the main catalytic active component, the cocatalyst, and the coating base material are 30%, 10%, and 60%, respectively, and the target of the catalytic coating and the carrier is The mass percentage ranges are: 23-25%, 77-75%, the sum of the mass percentages is 100%, and the planned configuration...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com