Platinum-based catalyst and preparation method and application thereof

A catalyst, platinum-based technology, applied in the field of electrochemical catalysis, can solve the problem of low utilization rate of platinum, and achieve the effect of improving utilization rate, good application prospect, and good conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

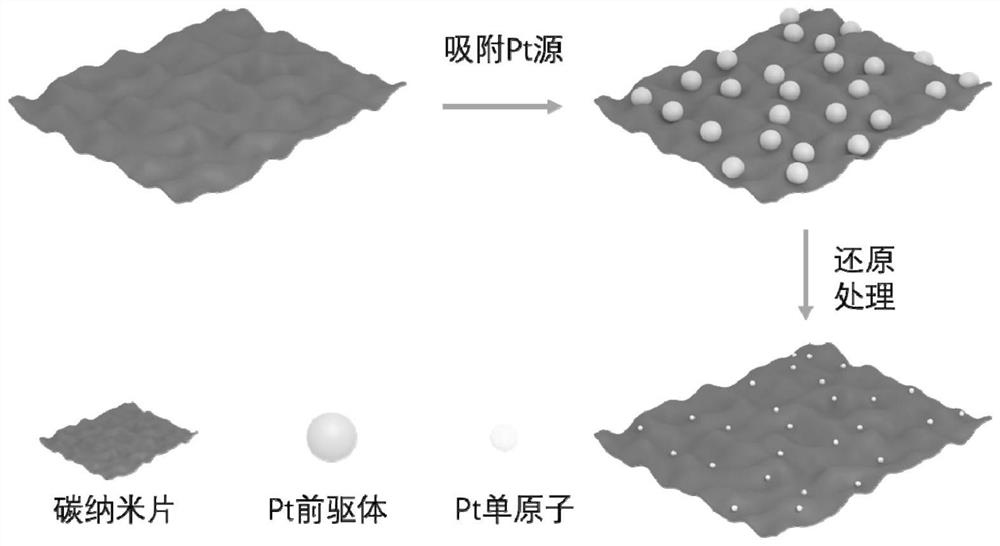

[0034] Correspondingly, the embodiment of the present invention also provides a preparation method of a platinum-based catalyst, which includes the following steps:

[0035] S1, providing melamine, carbon source, solvent and platinum source;

[0036] S2. Dispersing melamine and a carbon source in a solvent, drying and annealing to obtain a nitrogen-containing carbon carrier;

[0037] S3, preparing a nitrogen-containing carbon carrier and a platinum source into a precursor dispersion solution containing platinum ions;

[0038] S4, reducing the platinum ions in the precursor dispersion solution to obtain a platinum-based catalyst;

[0039] Among them, the annealing treatment includes two stages, the first stage is annealing at 500°C-600°C for 1h-2h at a heating rate of 1°C / min-2°C / min, and the second stage is annealing at 1°C / min-2 ℃ / min heating rate, annealing at 800℃-900℃ for 6h-8h.

[0040] The preparation method provided by the embodiment of the present invention uses mel...

Embodiment 1

[0060] The present embodiment provides a kind of preparation method of platinum-based catalyst, comprises the following steps:

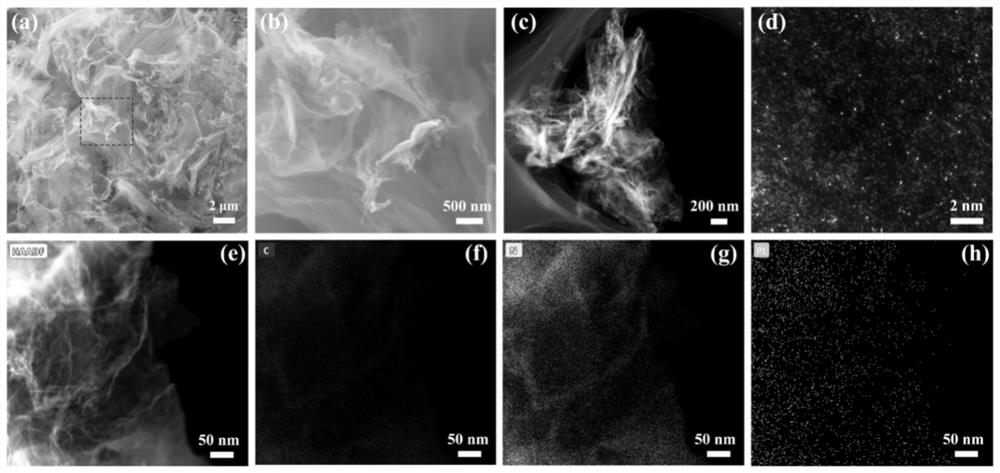

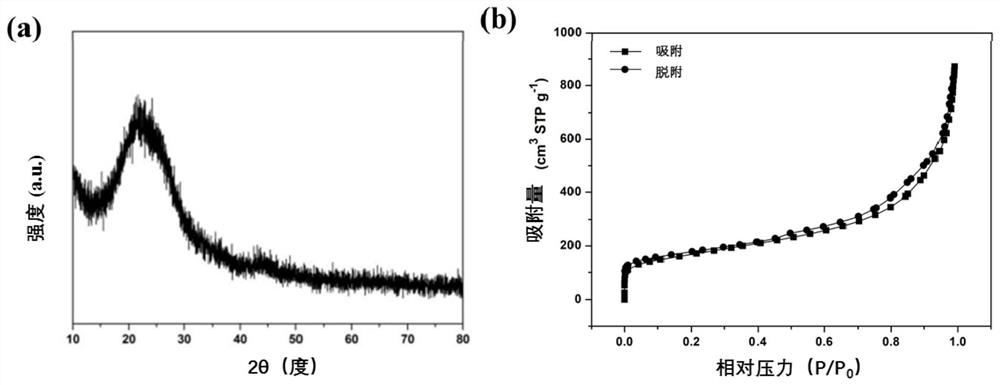

[0061] (11) Dissolve 10 g of melamine and 0.5 g of D(+)-glucosamine hydrochloride in a mixed solution of 35 ml of methanol and 15 ml of water, stir evenly, carry out rotary evaporation and drying, fully grind, and place the mixture powder in a tube In a type furnace, argon is used as an inert protective atmosphere for high-temperature annealing treatment. First, the heating rate is raised to 600°C at a rate of 1°C per minute for 1 hour, and then the heating rate is raised to 800°C at a rate of 2°C for 8 hours, and then the temperature is naturally lowered. , to obtain a carbon nanosheet carrier with high nitrogen content;

[0062] (12) Disperse 50 mg of carbon nanosheet carrier with high nitrogen content in 25 ml of deionized water, stir for 1 hour, and ultrasonically treat for 1 hour to obtain a carbon nanosheet carrier solution; slowly drop 1 ml of...

Embodiment 2

[0069] The present embodiment provides a kind of preparation method of platinum-based catalyst, comprises the following steps:

[0070] (21) Dissolve 10 g of melamine and 1 g of D(+)-glucosamine hydrochloride in a mixed solution of 35 milliliters of methanol and 15 milliliters of water, stir well, carry out rotary evaporation and drying, fully grind, and place the mixture powder in a tube In the furnace, argon is used as an inert protective atmosphere for high-temperature annealing treatment. First, the temperature is raised to 600°C at a rate of 1°C per minute and kept for 1 hour, and then the temperature is raised to 800°C at a rate of 2°C for 6 hours, and then the temperature is naturally lowered. A carbon nanosheet carrier with high nitrogen content can be obtained;

[0071] (22) Disperse 50 mg of carbon nanosheet carrier with high nitrogen content in 25 ml of deionized water, stir for 1 hour, and ultrasonically treat for 1 hour to obtain a carbon nanosheet carrier solutio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com