Activated carbon for air purification

An air purification and activated carbon technology, applied in the field of activated carbon, can solve the problems of poor adsorption capacity and poor sustainable capacity, and achieve the effects of strong sustained adsorption capacity, improved viscosity, and good air purification and adsorption capacity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

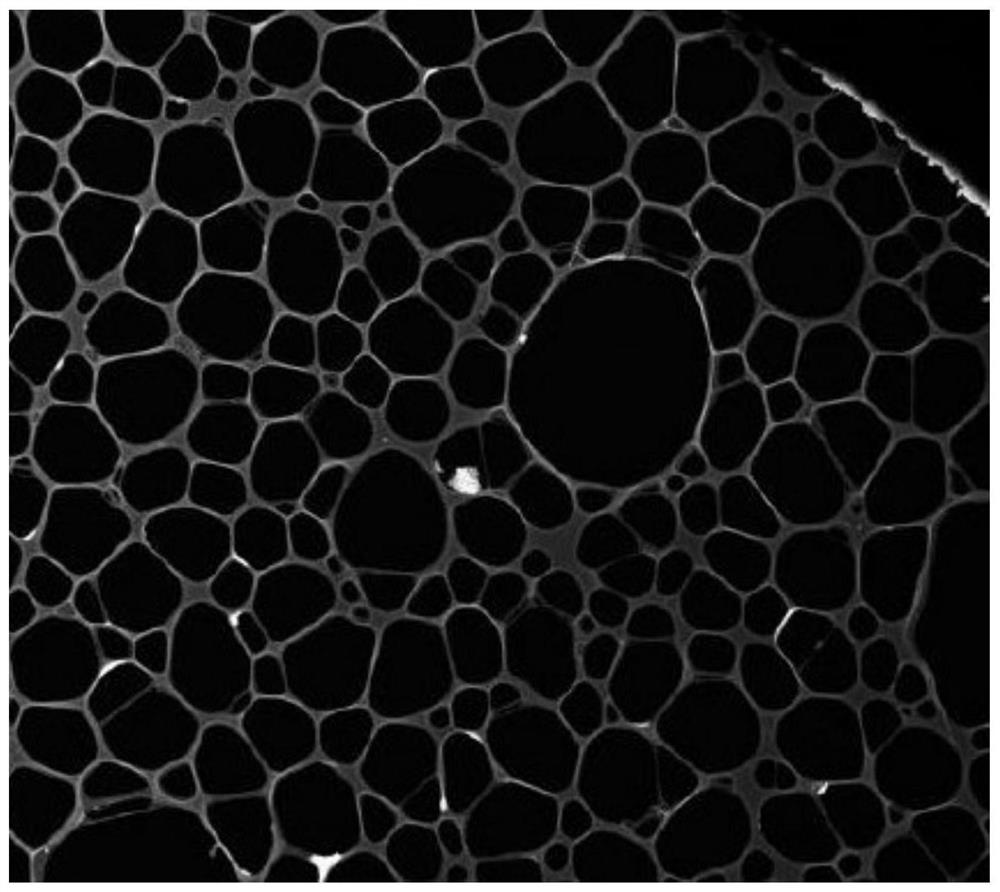

Image

Examples

preparation example Construction

[0020] Based on the activated carbon raw material, the preparation method of the activated carbon may further comprise the steps:

[0021] S1 raw material mixing; 50-77 parts of viscous bituminous coal and 23-50 parts of binder are mixed at one time, stirred evenly, and viscous bituminous coal formed by bonding is obtained;

[0022] Before mixing the S1 raw materials, crush and filter 50-77 parts of viscous bituminous coal;

[0023] Crushing makes the particles of raw coal uniform, which can not only improve the surface chemical cohesion between coal powder and binder, increase the strength of formed products, reduce the difficulty of forming, but also improve the air separation performance of activated carbon products. Reduce the particle size of coal particles as much as possible, the finer the crushing, the better the performance of the prepared activated carbon, and the crushing makes the particles of the raw coal uniform, which can not only improve the surface chemical co...

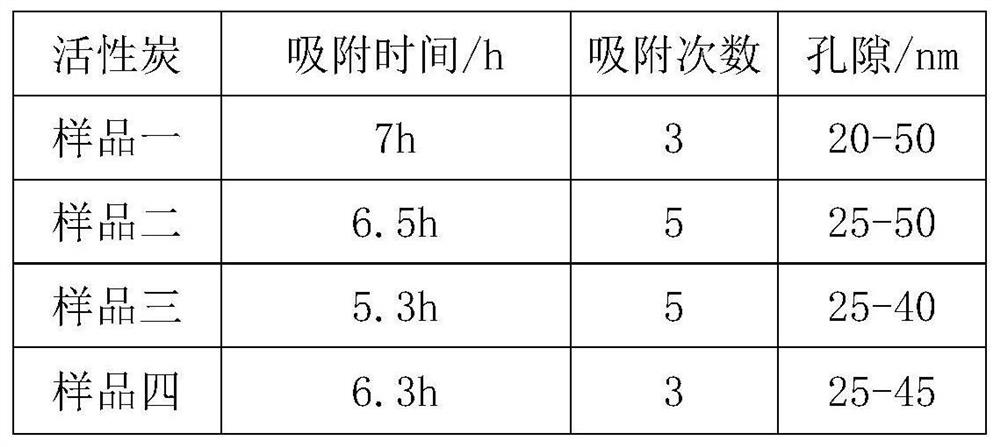

Embodiment 1

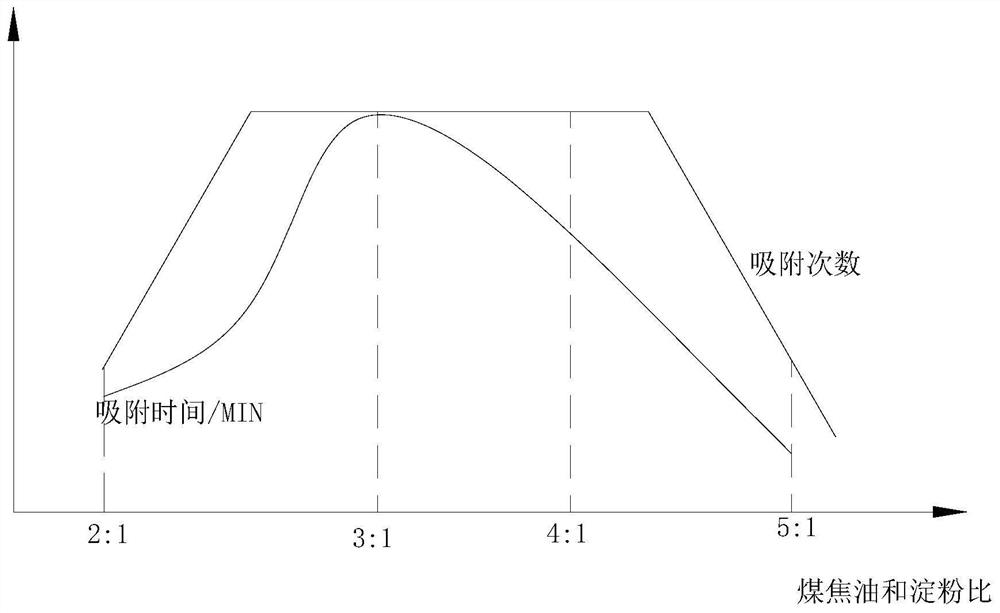

[0031] The raw material of activated carbon according to the present invention comprises: 50 parts of sticky bituminous coal, 50 parts of binder, wherein sticky bituminous coal is 1 / 3 coking coal, binder is the mixture of coal tar and starch, and coal tar The mass ratio to starch is 2:1.

[0032] Based on the activated carbon raw material, the preparation method of the activated carbon may further comprise the steps:

[0033] S1 raw material mixing; 50 parts of viscous bituminous coal and 50 parts of binder are mixed at one time, stirred evenly, and viscous bituminous coal formed by bonding is obtained;

[0034] S2 Coal Quality Modification: Heat and pre-oxidize the cohesive bituminous coal obtained in S1 to promote the expansion of bituminous coal, initially release gas, make the coal fluffy, and obtain molten bituminous coal with a loose structure;

[0035]Specifically, the cohesive bituminous coal obtained in S1 is placed in a carbonization furnace and heated at a temperat...

Embodiment 2

[0041] The raw material of activated carbon according to the present invention comprises: 50 parts of sticky bituminous coal, 50 parts of binder, wherein sticky bituminous coal is 1 / 3 coking coal, binder is the mixture of coal tar and starch, and coal tar The mass ratio to starch is 5:1.

[0042] Based on the activated carbon raw material, the preparation method of the activated carbon may further comprise the steps:

[0043] S1 raw material mixing; 50 parts of viscous bituminous coal and 50 parts of binder are mixed at one time, stirred evenly, and viscous bituminous coal formed by bonding is obtained;

[0044] S2 Coal Quality Modification: Heat and pre-oxidize the cohesive bituminous coal obtained in S1 to promote the expansion of bituminous coal, initially release gas, make the coal fluffy, and obtain molten bituminous coal with a loose structure;

[0045] Specifically, the cohesive bituminous coal obtained in S1 is placed in a carbonization furnace and heated at a tempera...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com