LSTM-based continuous real-time prediction method for moisture of environmental temperature and humidity in tobacco shred process

A technology for real-time forecasting of environmental temperature and humidity, which is applied in the fields of tobacco, tobacco preparation, and tobacco processing, can solve the problems that the potential influence of environmental temperature and humidity cannot be considered, the stability rate of tobacco moisture content decreases, and it is difficult to predict accurately in real time. Applicability and real-time performance, improving prediction accuracy and training speed, and good fitting effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

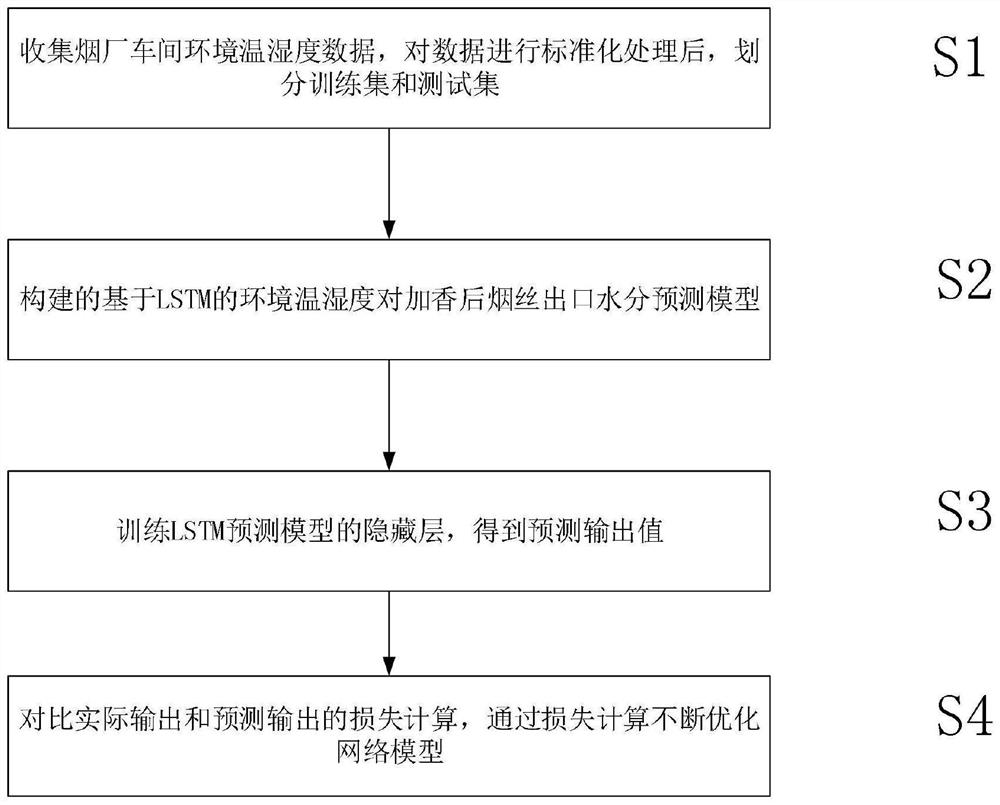

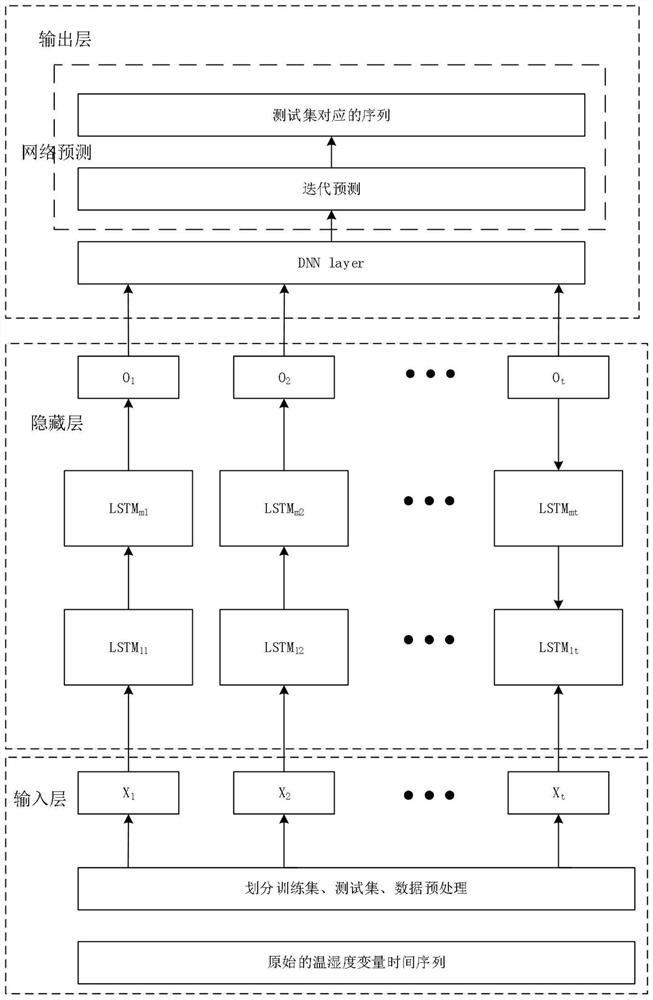

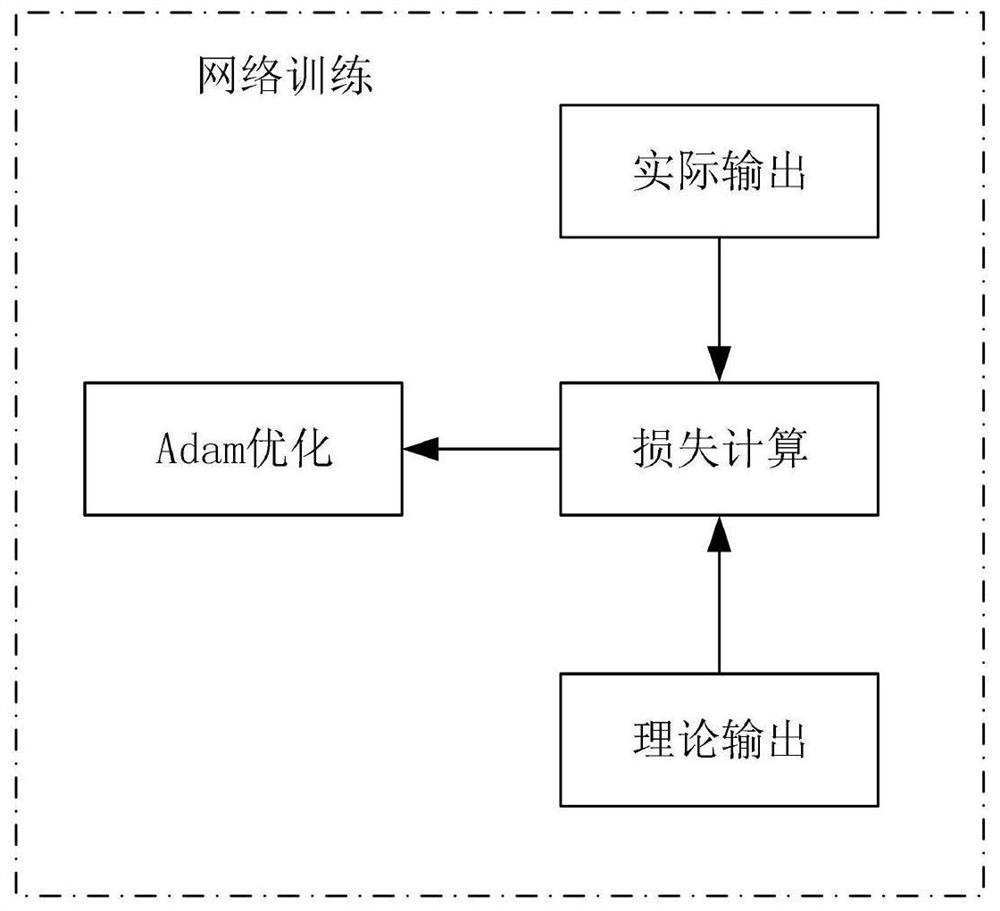

[0043] In this implementation, an LSTM-based method for continuous real-time prediction of ambient temperature and humidity in the shredded tobacco process is implemented. Deep learning iterative prediction method, analyzing the impact of environmental temperature and humidity in the process of moisture analysis and prediction on the moisture of cut tobacco outlet after flavoring, and establishing a real-time prediction model for moisture content of cut tobacco after flavoring; through the model solution, the predicted environment can be obtained The influence trend of temperature and humidity on the moisture yield of shredded tobacco after flavoring is finally tested by comparing the predicted value of the model with the measured value. Specifically, please refer to figure 1 As shown, it specifically includes the following steps:

[0044] S1: Collect the temperature and humidity data of the tobacco factory workshop environment. The collected data comes from the moisture content...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com