Double-heat-supply type tea leaf fixation and carding machine

A greening machine and tea technology, which is applied in tea treatment before extraction, air heater, fluid heater, etc., can solve the problems of reducing heat utilization rate and difficult temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

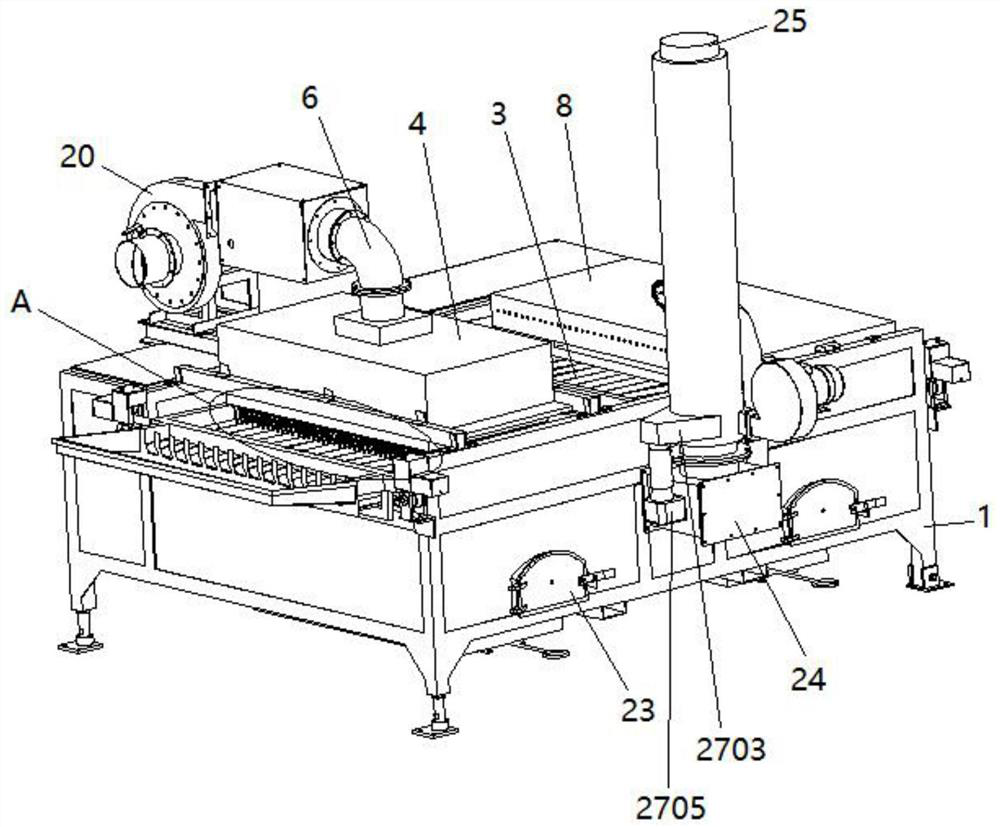

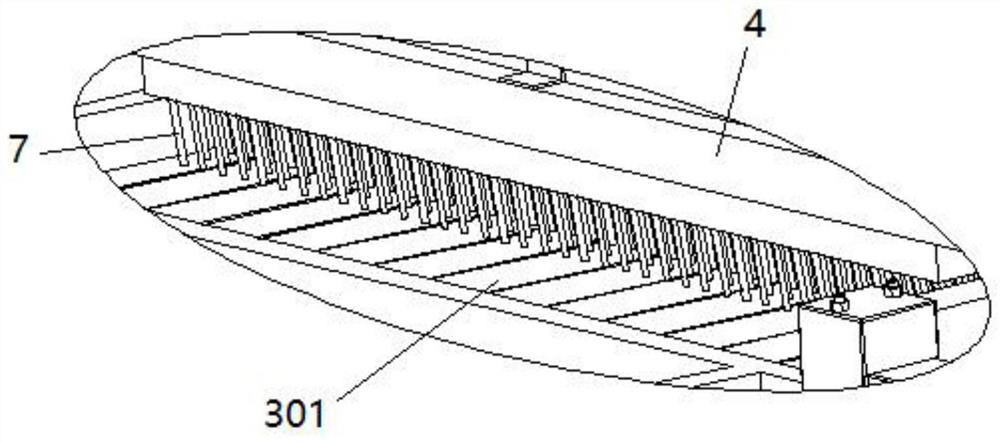

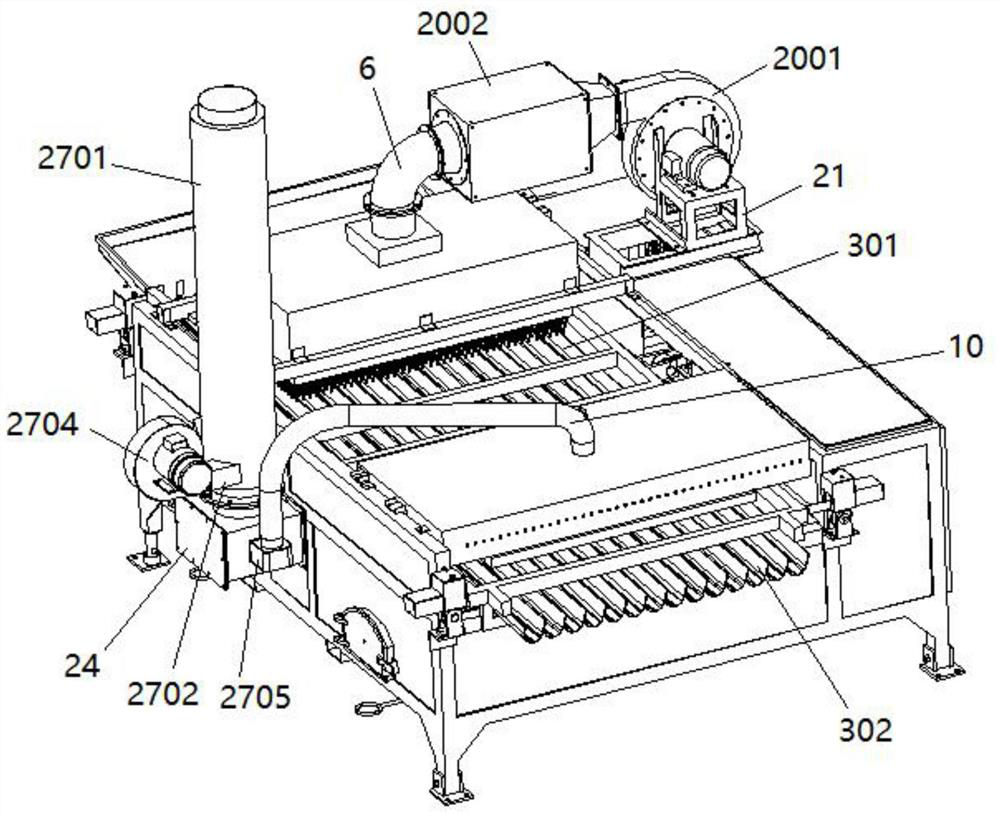

[0040] see Figure 1-11 , a double-heating type tea finishing machine, including a frame 1, a pot frame 2 that can reciprocate along the width direction of the frame 1, and a U-shaped groove pot group 3 on it, and the front of the pot frame 2 , the rear end is respectively fixedly connected with the baffle plate 201 under the U-shaped tank group 3, the front section of the U-shaped tank group 3 is the finishing section 301, and the rear section is the finishing section 302, and the frame 1 is fixed at the finishing section 301. The hot air box 4 and the first combustion chamber 5 are correspondingly fixed above and below, the hot air box 4 is connected with the first heating pipeline 6, and the bottom of the hot air box 4 is respectively connected with a U-shaped tank connected to its interior, inclined and facing the U-shaped tank. Several air nozzles 7 of group 3;

[0041] On the frame 1, a hot air cover 8 and a second combustion chamber 9 are correspondingly fixed above an...

Embodiment 2

[0069] see Figure 12 The difference between this embodiment and the first embodiment is that the hot blast generator in the first embodiment is replaced by a hot blast stove 33, and the hot blast stove 33 is used to heat the hot blast box 4, and the first heat supply pipeline 6 passes through the pipe The road 34 is connected to the hot blast stove 33, and other parts, corresponding structures, and implementation processes are the same as those in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com