Organic vegetable planting equipment and planting method

A technology of organic vegetables and equipment, applied in the field of agriculture, can solve the problems of lack of pepper root protection, damage, and affecting the growth of peppers, and achieve the effects of ingenious design, high plant growth rate, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

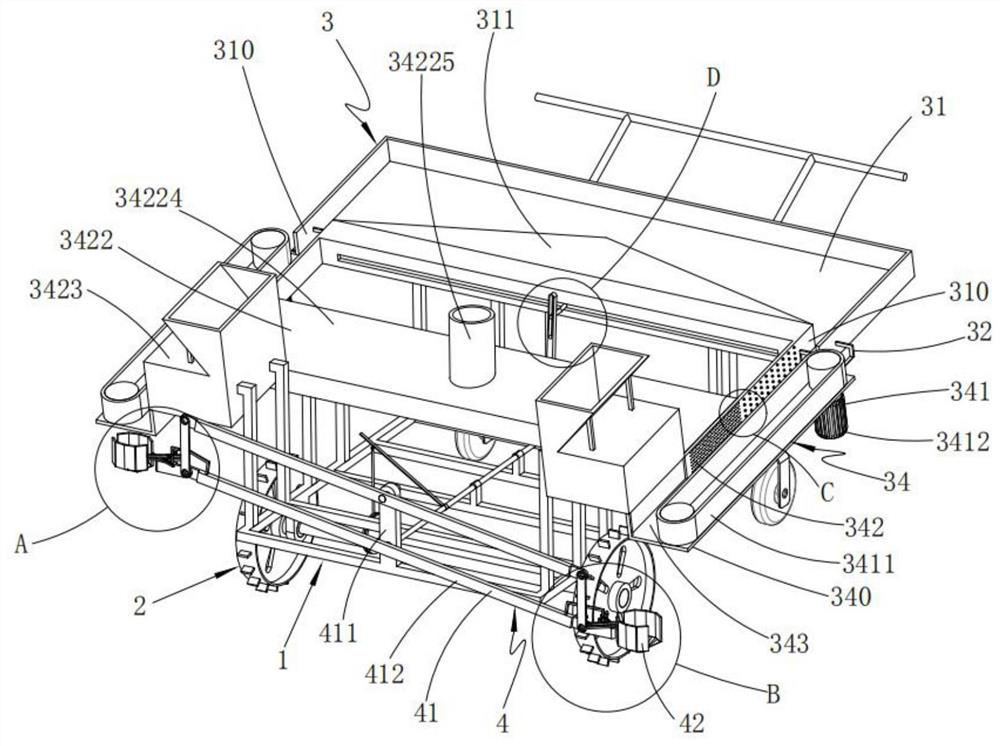

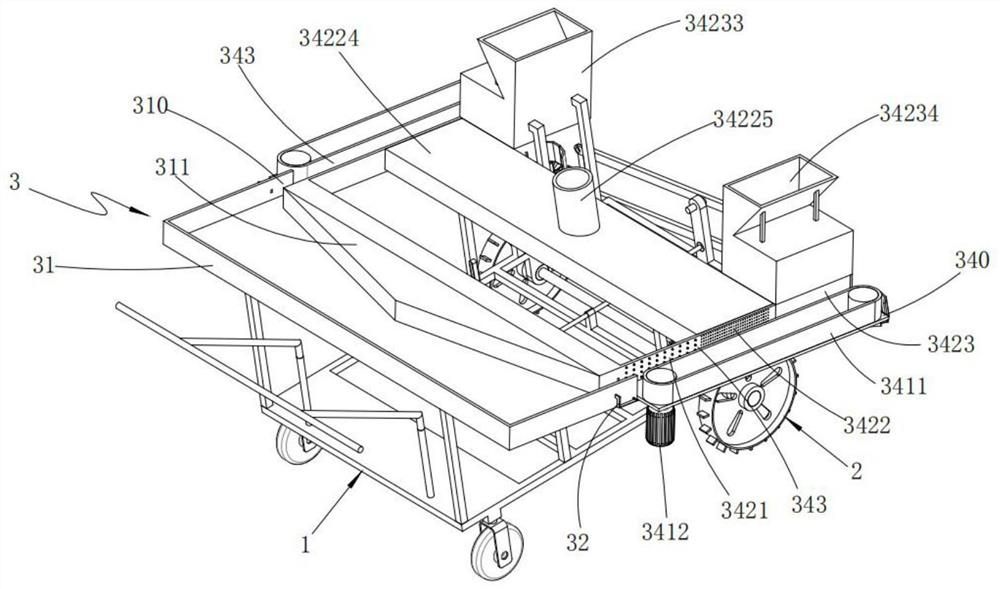

[0052] Such as figure 1 with figure 2 Shown, a kind of organic vegetable planting equipment comprises vehicle frame 1, the running mechanism 2 that is installed on vehicle frame 1 below and the planting equipment 10 that is installed on described vehicle frame 1 top, and described planting equipment 10 comprises:

[0053] The feeding device 3, the feeding device 3 includes a storage bin 31 installed at the tail of the vehicle frame 1 and symmetrically opened with two discharge ports 310, and two groups are arranged symmetrically on the left and right and correspondingly slidingly arranged on the discharge ports The limit assembly 32 in 310, the toggle assembly 33 that drives the two sets of limit assemblies 32 to move synchronously, and the two sets of output ports that are in one-to-one communication with the discharge port 310 and extend to the head of the vehicle frame 1 Material assembly 34; two groups of said conveying assembly 34 convey materials alternately;

[0054]...

Embodiment 2

[0081] Such as Figure 16 Shown, describe a kind of organic vegetable planting method of the embodiment of the present invention two with reference to embodiment one, comprise the following steps:

[0082] Step 1: Vegetable seedlings are discharged, the movement of the walking mechanism 2 drives the toggle assembly 33 to move through the transmission device 5, and then drives the limit assembly 32 to move laterally, and a vegetable seedling and earthwork enter the material delivery channel 343 on one side from the storage bin 31 Inside;

[0083] Step 2: Processing of vegetable seedlings. After step 1, the material distribution roller 34235 transports the straw in the material distribution box 34233 to the storage tank 34232, and then the power mechanism 341 drives the vegetable seedlings and the earthwork to rotate first, and the earthwork is carried out by the piercing unit 3421. Make holes, then rotate through the plastering unit 3422 to smear plant ash on the outside of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com