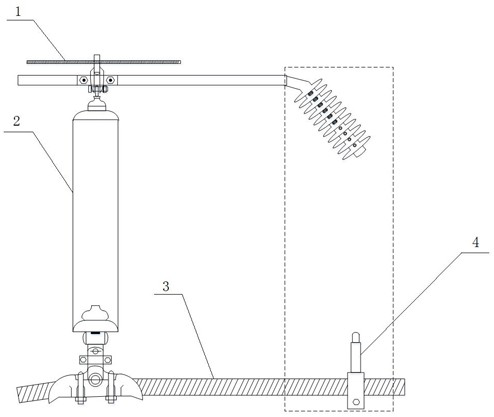

Multistage horn-shaped backflushing compression arc extinguishing lightning protection device

A lightning protection device and trumpet-type technology, which is applied to overvoltage arresters, electrical components, spark gaps, etc. that apply spark gaps, and can solve problems such as failure of parallel protection gap insulation coordination, difficult arc blowout, and line safety accidents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

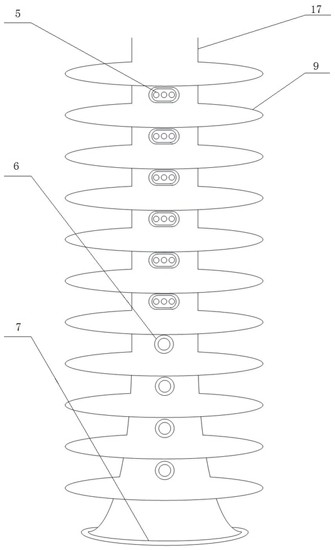

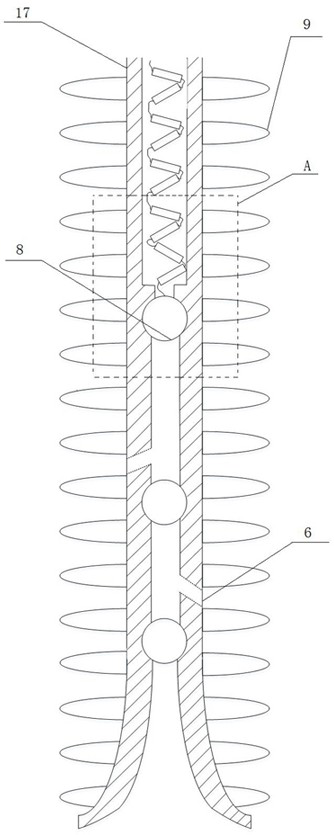

[0054] A multi-stage trumpet type recoil compression arc extinguishing lightning protection device, including a device main body 17; the outer surface of the device main body 17 is provided with several skirts 9; the interior of the device main body 17 is hollow, and the device main body 17 Both the inner diameter and the outer diameter gradually increase from top to bottom, so that the main body 17 of the device is trumpet-shaped, and an arc extinguishing path composed of several sections of arc extinguishing pipes 10 arranged obliquely from top to bottom is provided in the upper half space, and in the lower half space From top to bottom in the space, there are several arc guide balls I8 that are in close contact with the inner wall of the main body of the device; arc guide balls III11 are provided in the arc extinguishing pipe 10; between two adjacent ends of arc extinguishing pipes Connected by conductive connectors, the end of the last section of the arc extinguishing pipe ...

Embodiment 2

[0062] The difference between this embodiment and Embodiment 1 is that a metal ring 15 and a small platform 16 are also installed inside the device main body 17; the small platform 16 is arranged above the recoil injection port; the metal ring 15 is trumpet-shaped, and the metal ring 15 is installed on the small platform 16, and the outer surface of the metal ring 15 is close to the inner wall surface of the device main body 17.

[0063] The recoil injection port includes the recoil injection channel 6 and the bottom recoil injection port 7 at the bottom opening of the device main body 17; the outer diameter of the metal ring 15 is close to the inner diameter of the device main body 17, and its position is fixed by a small platform 16 to avoid the recoil process The middle metal ring 15 is shifted; similarly, a plurality of metal rings 15 can also be added in the side-stage recoil pipe, wherein a metal ring 15 is arranged above the recoil injection channel 6, and recoils at the...

Embodiment 3

[0065] The difference between this embodiment and Embodiment 1 is that the conductive connector is a three-way pipe. The tee pipe 13 is provided with two arc balls II 14 inside; an air gap is provided between the two arc balls II, and the length of the air gap is exactly the diameter of the radial pipe of the tee pipe 13 . The radial nozzle of the three-way pipe 13 is close to the inner wall surface of the main body of the device, and a corresponding compressed air injection channel is provided on the side wall of the main body of the device.

[0066] The arc ball II 14 is a spherical structure. When the arc enters the tee pipe 13, the jet airflow formed at the middle injection port of the tee pipe 13 acts on the arc to realize horizontal blowing. Since the device includes the arc extinguishing pipe 10 and the tee pipe 13, it can realize Horizontal and vertical blowing of the arc.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com