Measuring device based on machine vision

A measuring device and machine vision technology, applied in the direction of measuring devices, measuring instrument components, instruments, etc., can solve the problems of fixed measuring area and not suitable for measuring products of different sizes.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

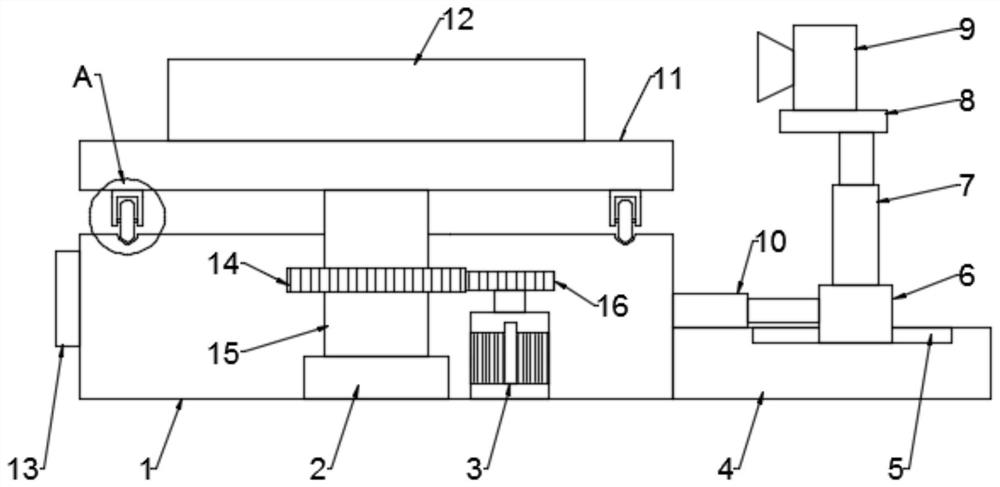

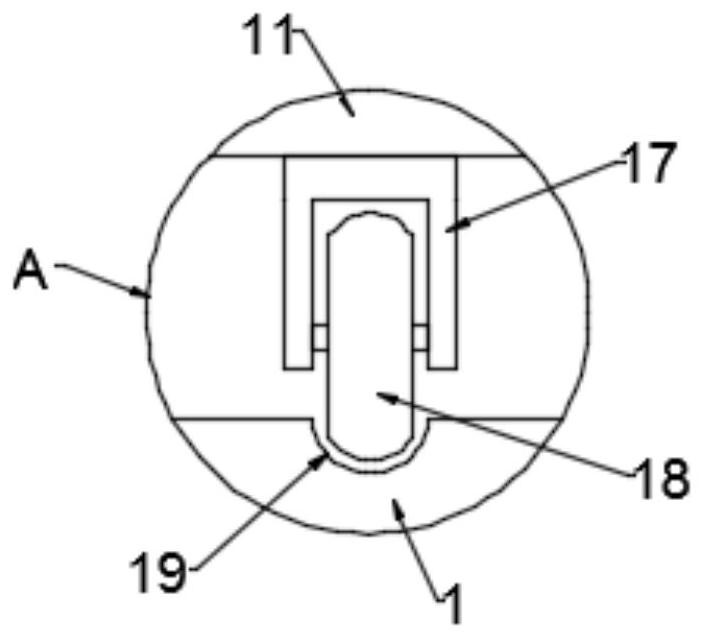

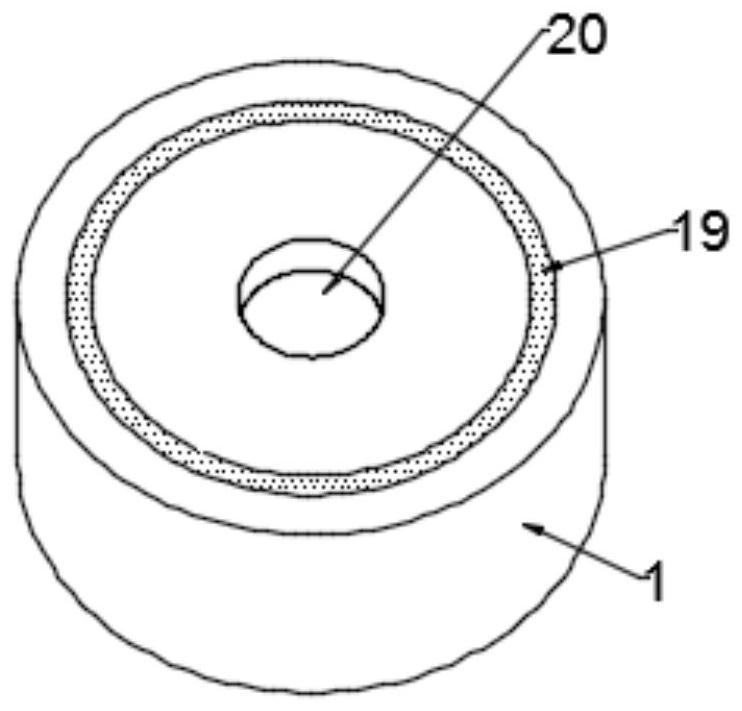

[0038] see Figure 1-3 , in the embodiment of the present invention, a measuring device based on machine vision includes a first base 1 and a second base 4, and the upper sides of the first base 1 and the second base 4 are respectively provided with a support base 11 and an industrial camera 9;

[0039] The measuring device based on machine vision also includes a control mechanism for changing the measuring area.

[0040] Further, the regulating mechanism includes a rotating mechanism for driving the support base 11 to rotate and an adjusting mechanism for adjusting the position of the industrial camera 9 .

[0041] Specifically, the rotating mechanism includes a driving assembly and an auxiliary assembly.

[0042] The drive assembly includes a motor 3, a rotating shaft 15 and a single-chip microcomputer 13;

[0043] The rotating shaft 15 is installed at the center of the bottom surface of the support seat 11, and the center of the top wall of the first base 1 is provided wi...

Embodiment 2

[0058] see Figure 4-5 , in the embodiment of the present invention, a measuring device based on machine vision is different from Embodiment 1 in that a slide bar 23 is provided inside the support seat 11, and a splint 22 is slidably connected to the slide bar 23, and the splint 22 is symmetrical set of two;

[0059] The top wall of the support base 11 is provided with a strip-shaped slideway 24 matched with the splint 22, and the top of the splint 22 passes through the strip-shaped slideway 24 and extends to the upper side of the support base 11;

[0060] A spring 21 is provided between the splint 22 and the side wall of the support seat 11, and the spring 21 is sleeved on the slide bar 23; through the cooperation of the spring 21, the splint 22 and the slide bar 23, the The product 12 to be measured avoids displacement of the product 12 to be measured during the measurement process, which affects the measurement result.

[0061] The working principle of the embodiment of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com