System and process adopting regenerative heating furnaces to heat acidic circulating gas

A technology for acid gas and circulating gas, which is used in the reduction of gas emissions, lighting and heating equipment, furnaces, etc., and can solve the problems of ineffective utilization, high requirements for acid gas heating systems, and inability to meet

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The specific embodiment of the present invention will be further described below in conjunction with accompanying drawing:

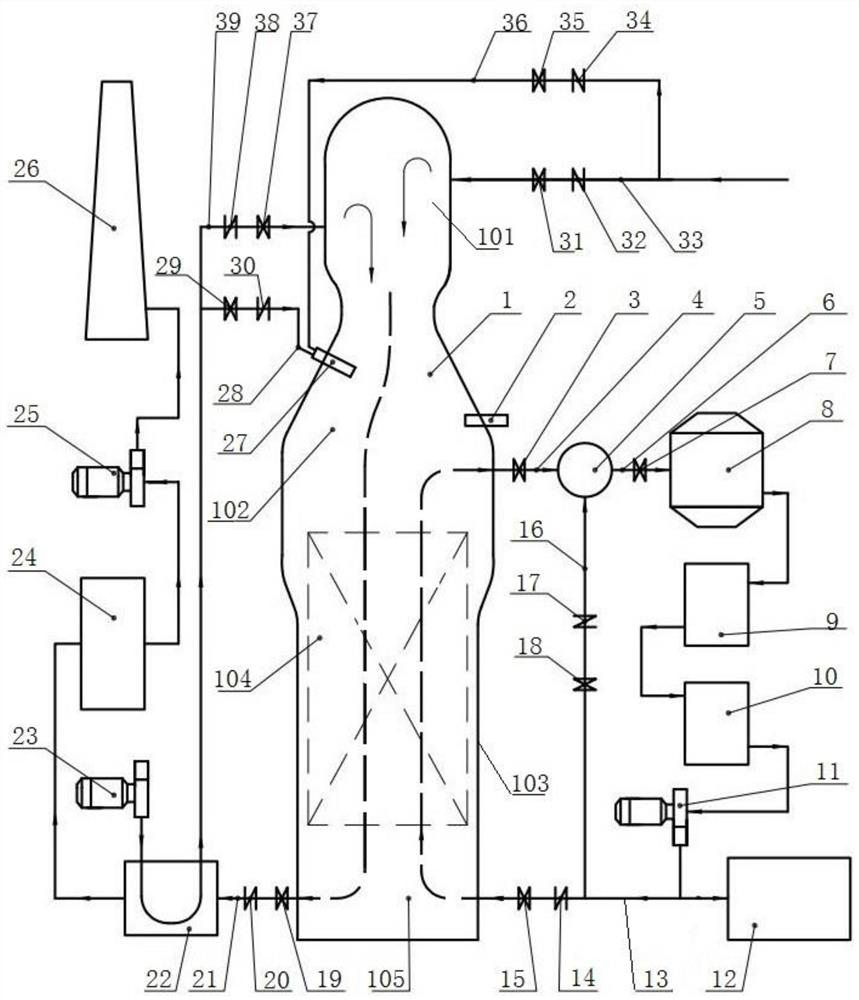

[0023] Such as figure 1 As shown, a system for heating acidic circulating gas using a regenerative heating furnace according to the present invention includes a regenerative heating furnace 1, a mixing chamber 5, a decomposition furnace 8, a settling chamber 9, a metal film powder collector 10, a Heater 22, deacidification device 24 and chimney 26; described regenerative heating furnace 1 is made up of ceramic burner 101, combustion chamber 102 and regenerator 103 arranged sequentially from top to bottom; ceramic burner 101 is provided with natural gas Inlet and combustion-supporting air inlet, the top side of the combustion chamber 102 is provided with an ignition igniter 27, and the lower part of the combustion chamber 102 is provided with a high-temperature acid gas outlet; The bottom is provided with a low-temperature acid gas inlet and a flu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com