Hot water storage tank capable of improving output rate of hot water

A technology of hot water storage tank and output rate, which is applied in the parts of solar collectors, the fluid circuit connection of solar collectors, solar thermal energy, etc., which can solve the problem of accelerating the cooling speed of hot water and increasing the heat loss of hot water , reduce hot water output rate and other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

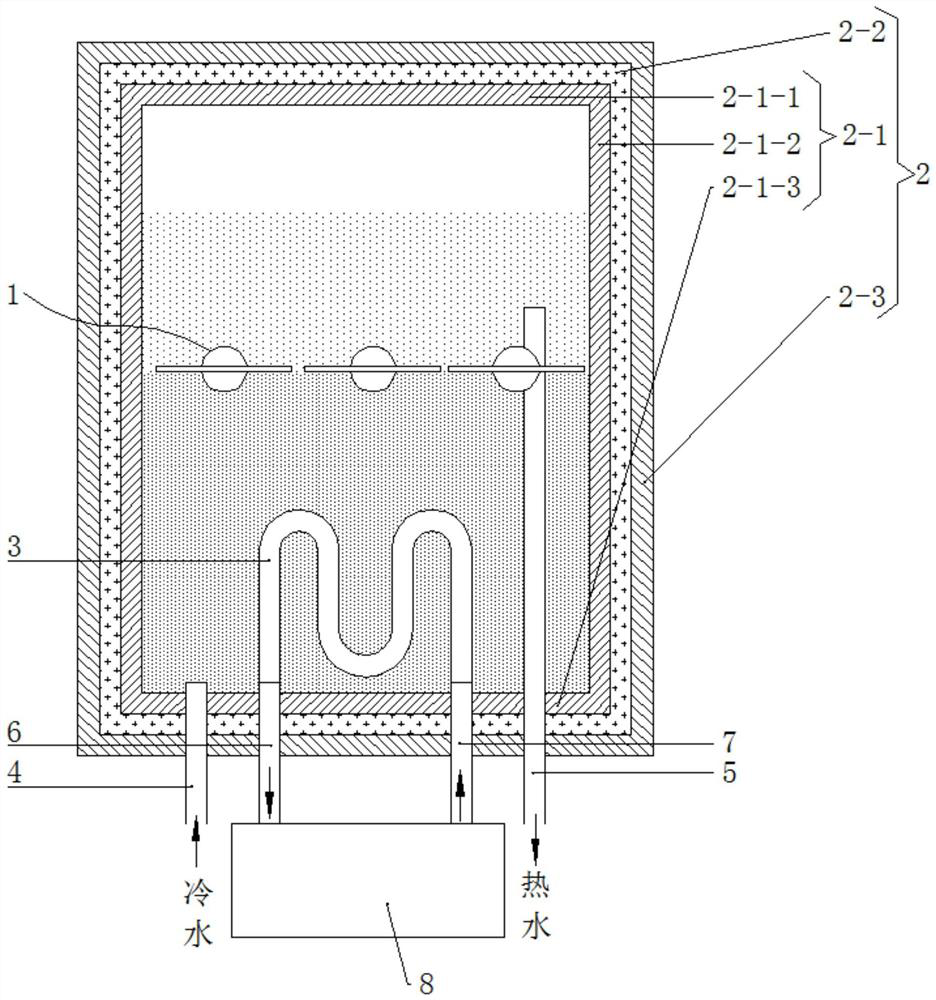

[0045] A hot water storage tank for increasing the output rate of hot water, comprising a tank body 2, in which a floating plate 1 for separating cold water and hot water is installed, and the density of the hot water, the density of the floating plate 1, and the density of cold water increase sequentially Big.

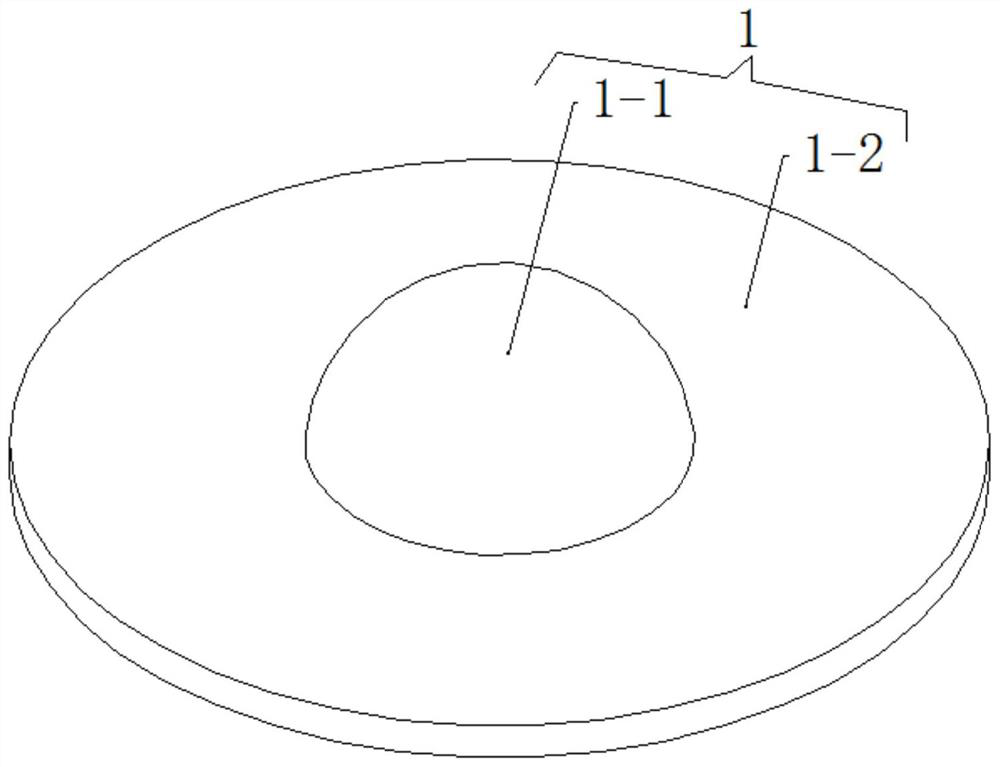

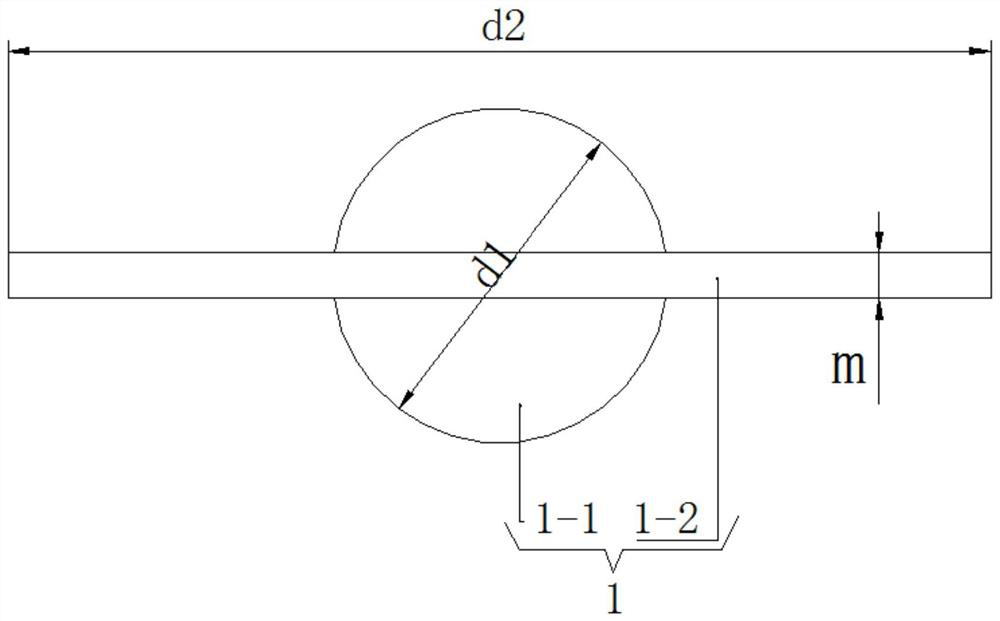

[0046] Such as figure 1 and figure 2 As shown, the floating disc 1 is made of silica gel. The floating disk 1 includes a sphere 1-1 and an annular disk 1-2 arranged on the edge of the sphere 1-1, and the sphere 1-1 and the annular disk 1-2 are integrally formed. The ball diameter d1 of the sphere 1-1 is 20 mm, the outer diameter d2 of the annular disc 1-2 is 60 mm, and the thickness m of the annular disc 1-2 is 2 mm. The weight of the floating disc 1 is 9.083g (the density of the floating disc 1, that is, the weight-to-volume ratio is 0.985g / cm 3 ).

[0047] Such as image 3 As shown, the box body 2 includes an inner tank 2-1, an insulating layer 2-2, and an oute...

Embodiment 2

[0057] The floating disc 1 can not only be solid, but also hollow. Specifically, on the basis of embodiment 1, this embodiment 2 makes the following improvements: as Figure 4 As shown, the sphere 1-1 of the floating disk 1 is provided with a spherical cavity, the ball diameter d3 of the spherical cavity is 6.478mm, the density of silica gel is 1.03, the weight of the floating disk 1 is 4.168g, and the weight-to-volume ratio of the floating disk 1 is 0.995g / cm 3 .

Embodiment 3

[0059] In embodiment 1 or embodiment 2, the floating disk 1 will age after being used for a long time. On the one hand, cracks or deformations will appear in the aging floating plate 1, thereby reducing the area of the floating plate 1 separating the hot water layer and the cold water layer, making the agitation of the hot water and cold water increase again, and increasing the pressure of the hot water. The heat is lost, the cooling speed of hot water is accelerated, and the output rate of hot water is reduced. On the other hand, the aging floating disk 1 made of silica gel will emit harmful substances, thereby reducing safety.

[0060] In this regard, a new floating disk 1 needs to be replaced. But, in embodiment 1 or embodiment 2, do not offer the opening that can pick and place floating disk 1 on the liner 2-1, so floating disk 1 cannot be replaced.

[0061] In this regard, on the basis of embodiment 1 or embodiment 2, the present embodiment 3 makes the following impro...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Outer diameter | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com