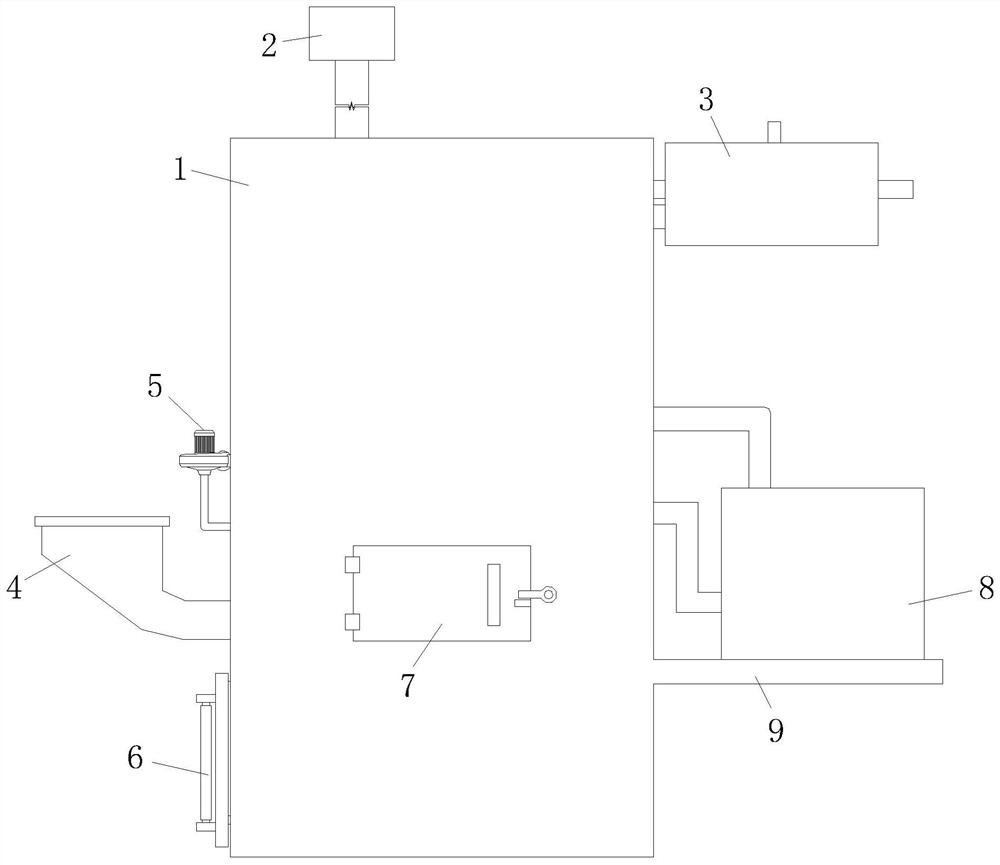

Municipal solid waste incineration power generation system

A municipal solid waste, incineration power generation technology, applied in the direction of incinerators, combustion methods, combustion types, etc., can solve the problems of inconvenient material cleaning, insufficient garbage combustion, harmful smoke and dust emissions, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

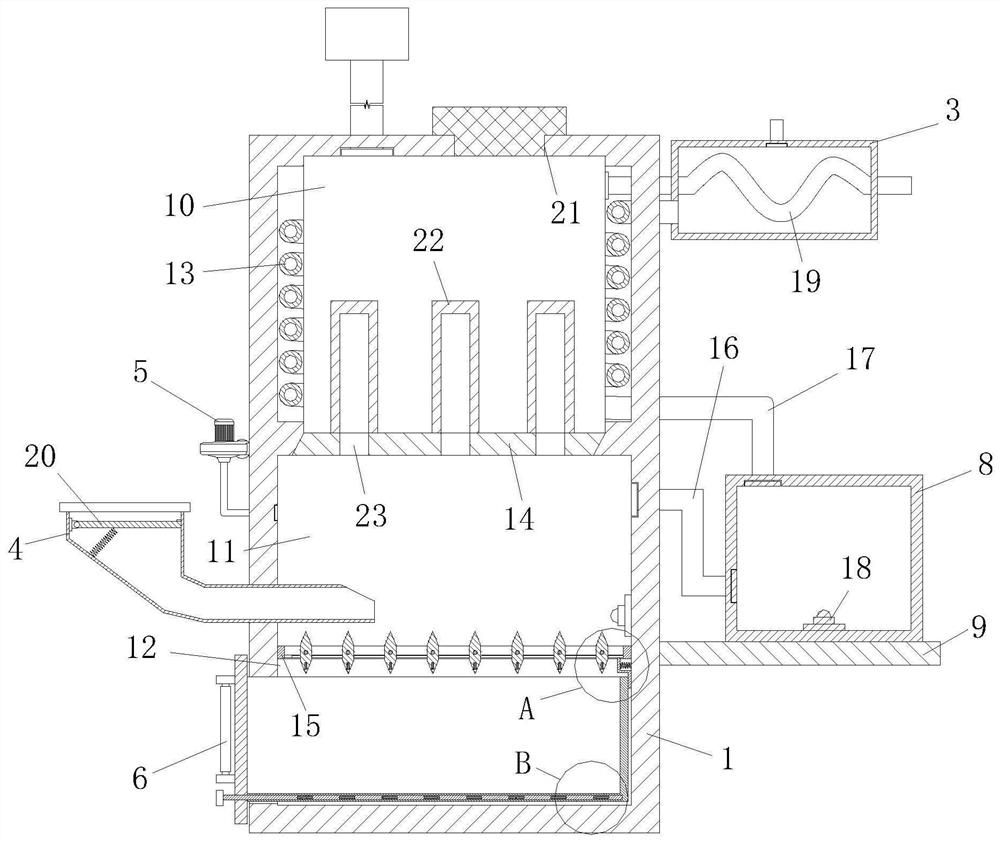

[0025] As an embodiment of the present invention, an opening is provided on the left side of the housing 1, and the opening communicates with the collection chamber 12, and the waste residue collection box 6 is slidably connected to the opening; the waste residue collection box 6 is located in the collection chamber 12; during operation, The material produced by the domestic waste after burning falls in the waste residue collection box 6 through the grid plate 15, and the waste residue collection box 6 can be conveniently collected through the opening to collect the waste residue collection box 6. The accumulation of burned substances affects the combustion of domestic garbage, and it is more convenient to clean the collection cavity 12 through the waste residue collection box 6 .

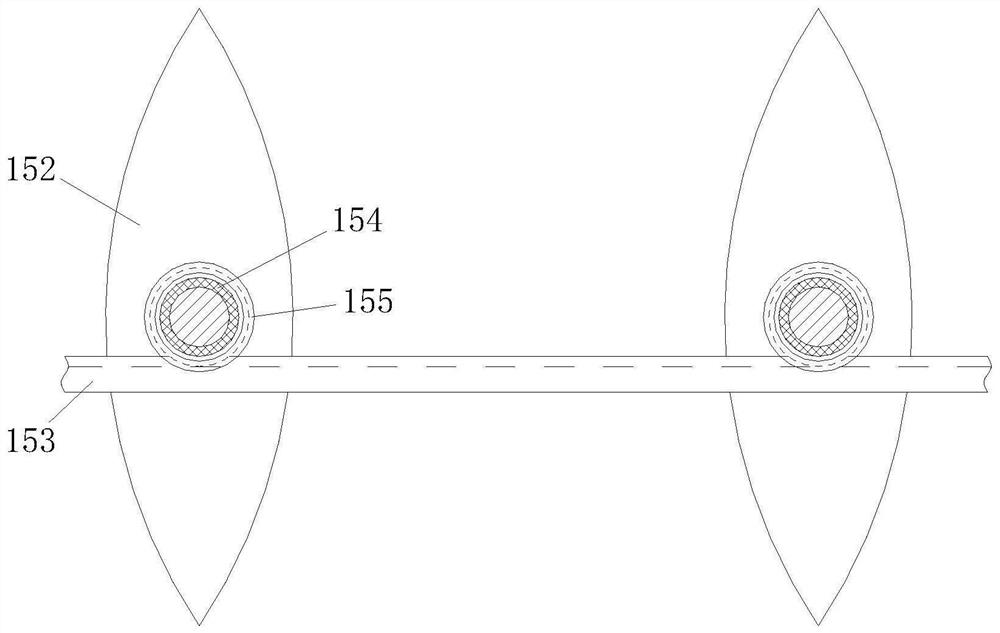

[0026] As an embodiment of the present invention, the grid plate 15 includes a frame 151 and uniformly arranged rotating plates 152; the frame 151 is fixedly connected to the inner wall of the housi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com