Pulse type supercritical fluid printing and dyeing process and device

A technology of supercritical fluid and printing and dyeing process, applied in the field of printing and dyeing, can solve the problems such as the failure to recycle the dye liquor, the lack of thermal insulation measures in the dyeing kettle, and the uniformity of product dyeing.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

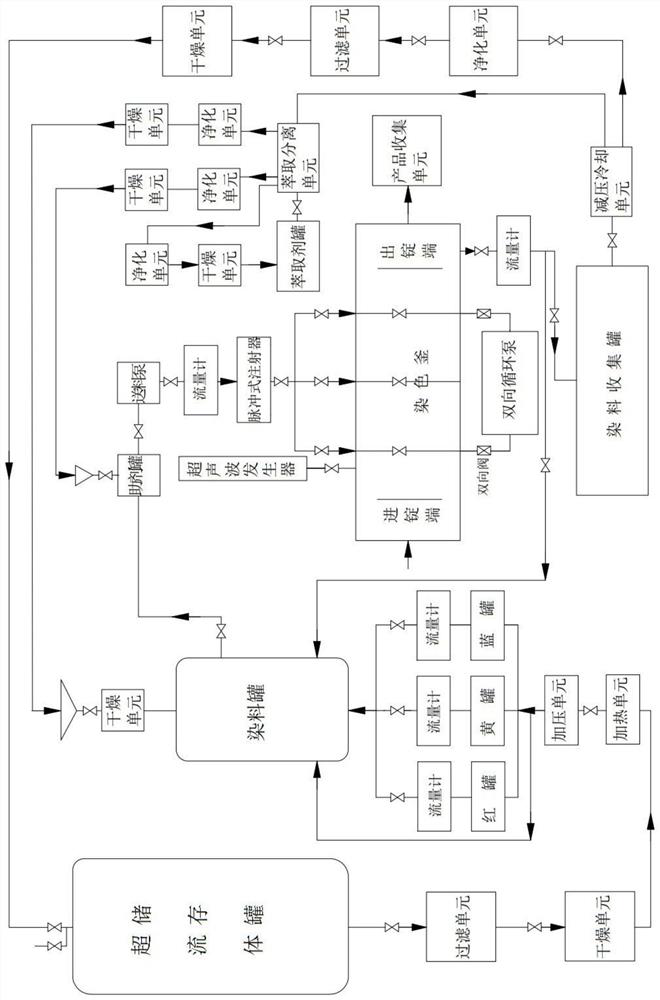

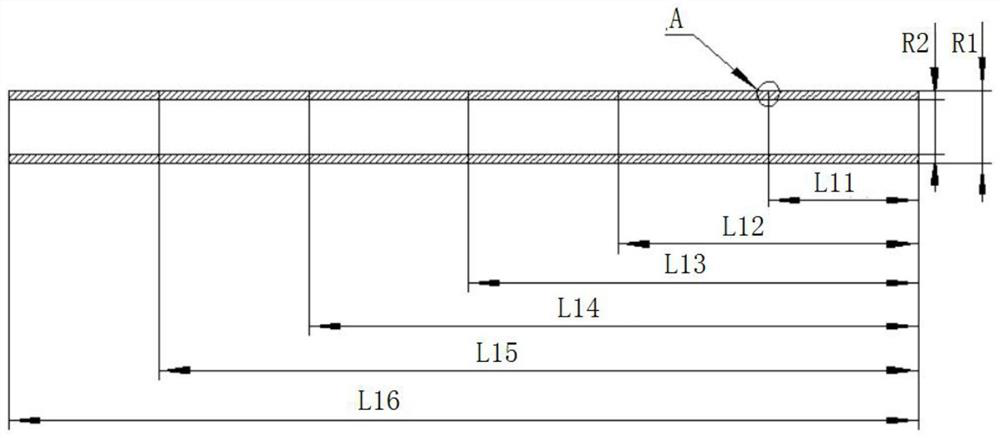

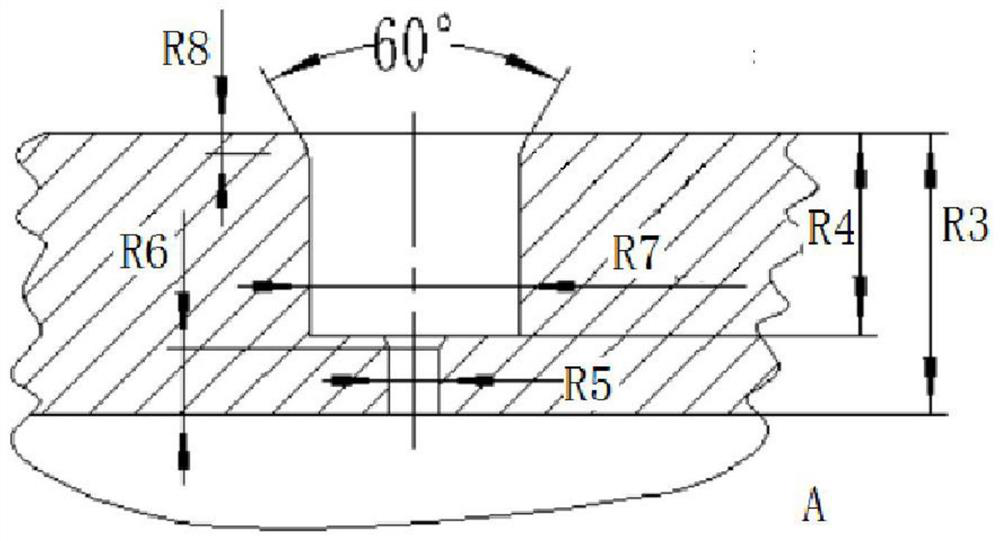

[0046] see figure 1 As shown, this embodiment provides a pulsed supercritical fluid printing and dyeing device, including: a superfluid storage tank, a three primary color tank, a dye tank, a pulse generator, a dyeing tank, a dye collection tank, a decompression cooling unit and an extraction separation unit , the three primary color tanks are composed of red tanks, yellow tanks and blue tanks arranged in parallel, the red tanks, yellow tanks and blue tanks are respectively equipped with red, yellow and blue three primary color dyes, and the red, yellow and blue three primary color dyes are installed according to requirements. They are mixed with supercritical carbon dioxide to form a specific color dye solution. The dyeing kettle is composed of 24-25 meters of pipelines, covered with a thermal insulation layer; and divided into four sections along its length, each section of the dyeing kettle is equipped with the pulse injector, ultrasonic Generator and bi-directional circul...

Embodiment 2

[0064] see figure 1 As shown, based on the above pulsed supercritical fluid printing and dyeing device, this embodiment provides a pulsed supercritical fluid printing and dyeing process suitable for printing and dyeing for the first time or continuously printing and dyeing the same product, including the following steps: (1) Carbon dioxide or liquid nitrogen is converted into supercritical carbon dioxide or supercritical nitrogen from the superfluid storage tank through the filtration unit, drying unit, heating unit and pressurization unit in sequence, after pressurization and heat treatment; (2) the converted supercritical carbon dioxide Or supercritical nitrogen is passed into the red tank, yellow tank and blue tank of the three primary colors to mix with red, yellow and blue dyes, and then according to the spindle dyeing requirements, it is fed into the dye tanks in a certain proportion to form a dye solution; (3) using The pulse injector injects the dye solution into the d...

Embodiment 3

[0070] see figure 1 As shown, different from the above-mentioned embodiment 2, based on the above-mentioned pulsed supercritical fluid printing and dyeing device, this embodiment provides a pulsed supercritical fluid printing and dyeing process suitable for printing and dyeing products when production is stopped, including the following steps: (1) Convert liquid carbon dioxide or liquid nitrogen from the superfluid storage tank to supercritical carbon dioxide or supercritical nitrogen after sequentially passing through the filter unit, drying unit, heating unit and pressurizing unit after pressurization and heat treatment; (2) convert the converted supercritical Critical carbon dioxide or supercritical nitrogen are passed into the red tank, yellow tank and blue tank of the three primary colors respectively to mix with red, yellow and blue dyes, and then according to the dyeing requirements of the spindle, they are fed into the dye tanks in a certain proportion to form a dye sol...

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com