Antibacterial admixture for high-strength and high-performance concrete and preparation method of antibacterial admixture

A high-performance concrete and admixture technology, applied in the field of concrete, can solve the problems of weak antibacterial effect and inability to use

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

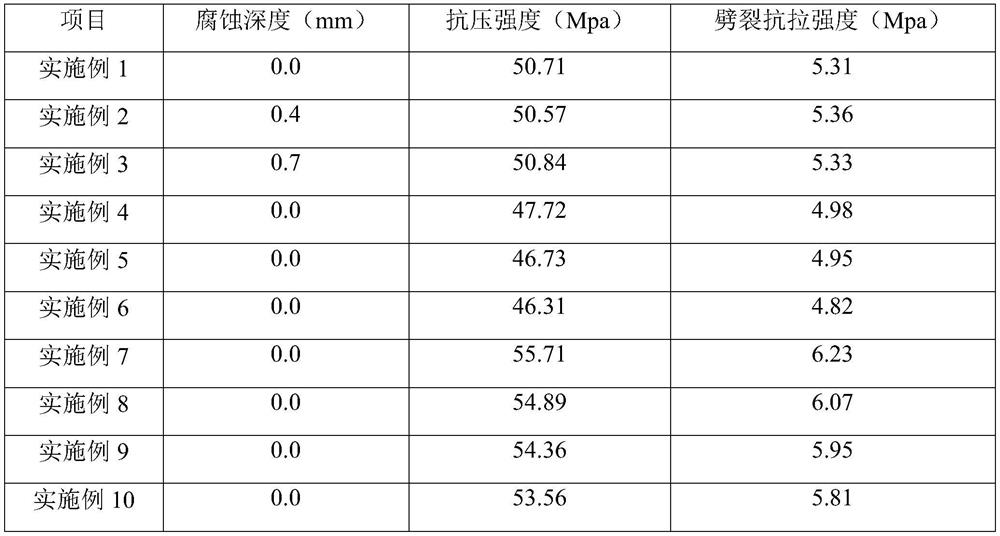

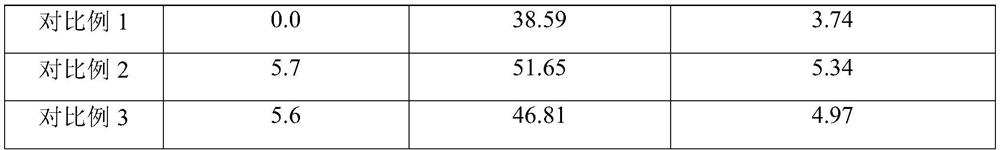

Examples

Embodiment 1

[0050] An antibacterial admixture for high-strength and high-performance concrete, obtained by mixing the following components by mass:

[0051] 25 parts of polycarboxylate water reducer;

[0052] 25 parts of chitosan-copper oxide composite antibacterial agent;

[0053] 15 parts of fly ash;

[0054] 2 parts of hydroxypropyl methylcellulose;

[0055] 1 part bentonite;

[0056] 1 part polyacrylamide.

[0057] The present embodiment fly ash selects Class I fly ash.

[0058] The polyacrylamine used in this embodiment is nonionic polyacrylamide.

[0059] The present embodiment bentonite selects organic bentonite.

[0060] The present embodiment hydroxypropyl methylcellulose selects instant hydroxypropyl methylcellulose for use.

[0061] In the chitosan-copper oxide composite antibacterial agent of this embodiment, the degree of deacetylation of chitosan is 95%, and the molecular weight is 70000.

[0062] The preparation method of present embodiment chitosan-copper oxide com...

Embodiment 2

[0071] The formula and preparation method of this example are basically the same as those of Example 1, except that in the chitosan-copper oxide composite antibacterial agent of this example, the degree of deacetylation of chitosan is 90%, and the molecular weight is 50,000.

Embodiment 3

[0073] The formula and preparation method of this example are basically the same as those of Example 1, except that in the chitosan-copper oxide composite antibacterial agent of this example, the degree of deacetylation of chitosan is 88%, and the molecular weight is 100,000.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com