Calcium carbide cooling and heat dissipation device

A heat-dissipating device and calcium carbide technology, applied in the field of heat-dissipating devices and calcium carbide cooling and heat-dissipating devices, can solve the problems of poor cooling effect and the like

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

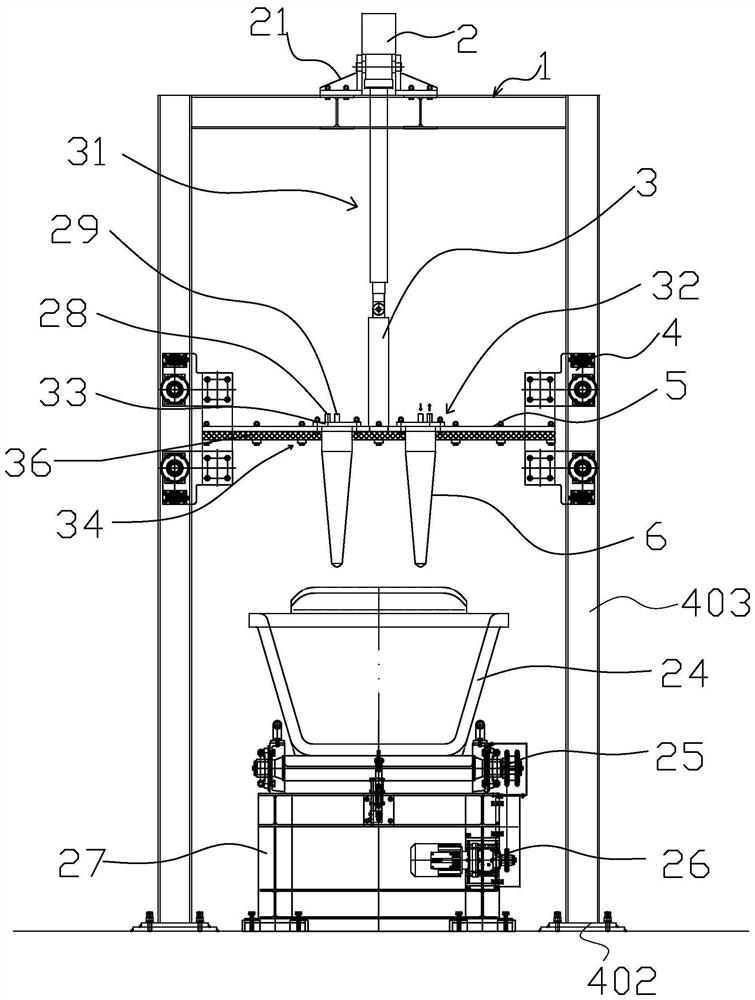

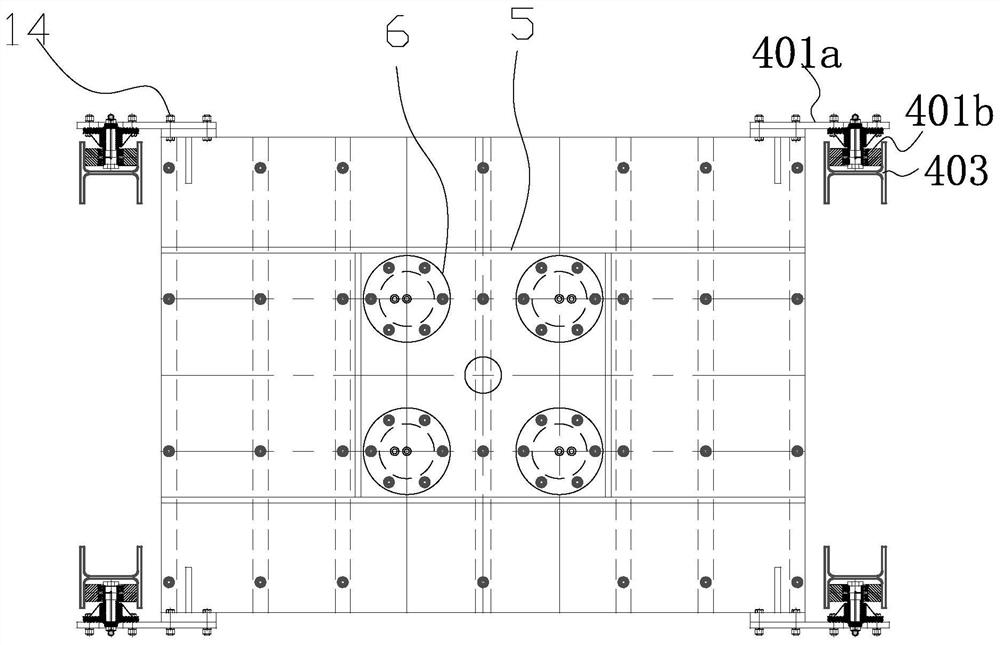

[0027] Such as Figure 1-4 As shown, the calcium carbide cooling and heat dissipation device includes a frame 1 and a support frame 5 arranged on the frame 1. A lifting mechanism capable of driving the support frame 5 up and down in the vertical direction is provided between the support frame 5 and the frame 1. 31. The support frame 5 is provided with at least one insert body 6, and the insert body 6 is provided with a heat dissipation component. The heat dissipation component includes a heat exchange cavity arranged in the insert body 6, and the insert body 6 is provided with a heat exchange cavity communicating with the heat exchange cavity. Gas / liquid inlet 29 and gas / liquid outlet 28. After the insertion body 6 is inserted into the calcium carbide, the gas or liquid absorbed in the heat exchange cavity enters the heat exchanger through the gas / liquid outlet 28 for heat exchange and cooling, and then flows back into the heat exchange cavity through the gas / liquid inlet 29.

...

Embodiment 2

[0050] Such as Figure 5 As shown, the structure, principle, and embodiment steps of this embodiment are similar to those of Embodiment 1, and the differences are:

[0051] The heat exchange cavity includes a heat exchange channel 35 arranged in a spiral shape in the insert 6. One end of the heat exchange channel 35 is connected with the gas / liquid inlet 29 and the other end is connected with the gas / liquid outlet 28.

[0052] The working principle is: when the motor 26 is started, the hopper 24 placed on the raceway 25 is driven to move. When the hopper 24 placed on the raceway 25 moves below the support frame 5, the motor 26 stops, and the telescopic cylinder 2 drives the support through the connecting rod 3. The plate 5 moves downwards so that the insert 6 at the lower end of the support plate 5 is inserted into the calcium carbide in the hopper 24, the gas or liquid that absorbs heat in the heat exchange cavity enters the heat exchanger through the gas / liquid outlet 28 for heat ...

Embodiment 3

[0054] Such as Image 6 , 7 As shown, the structure, principle, and embodiment steps of this embodiment are similar to those of embodiment 1, except that: the inner end of the gas / liquid inlet 29 is fixed with an inlet pipe 291 located in the cavity 7, and the lower end of the inlet pipe 291 extends To the bottom of the cavity 7, an arc-shaped guide tube 292 extending outward is provided at the lower end of the inlet tube 291, and the arc-shaped guide tube 292 gradually slopes upward from the inner end to the outer end. The arc-shaped guide tube 292 can form a vortex in the cavity 7.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com