Method special for transporting heavy prefabricated arch bridge assembled box girder

A technology of prefabricated arch bridges and assembled boxes, which is applied in the direction of transportation and packaging, transportation of passenger cars, trucks, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] The technical solutions of the present invention will be further specifically described below through the embodiments and in conjunction with the accompanying drawings.

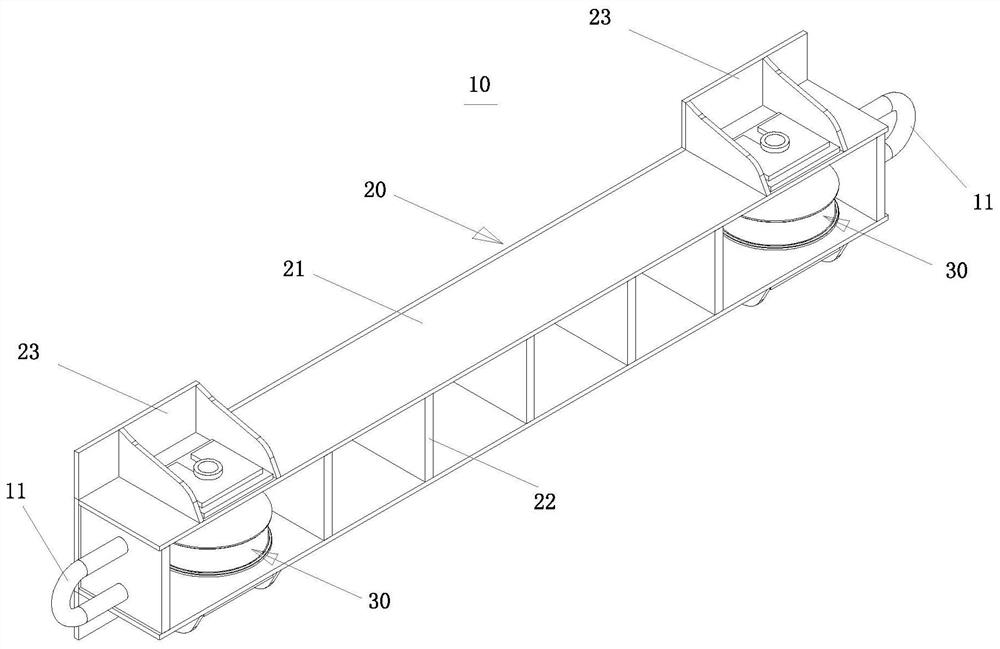

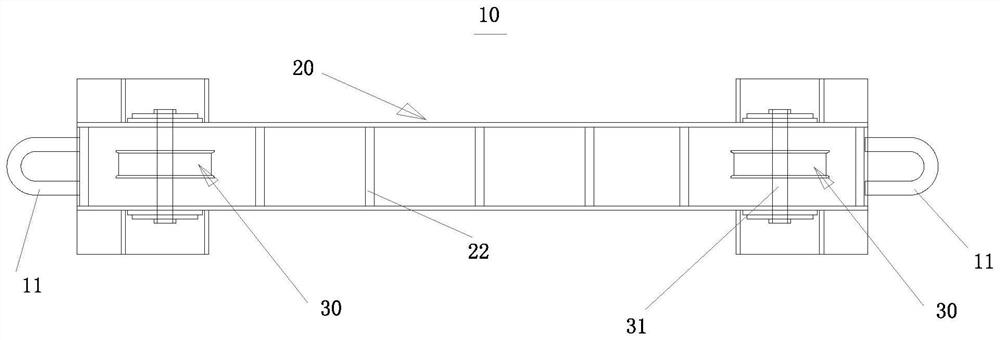

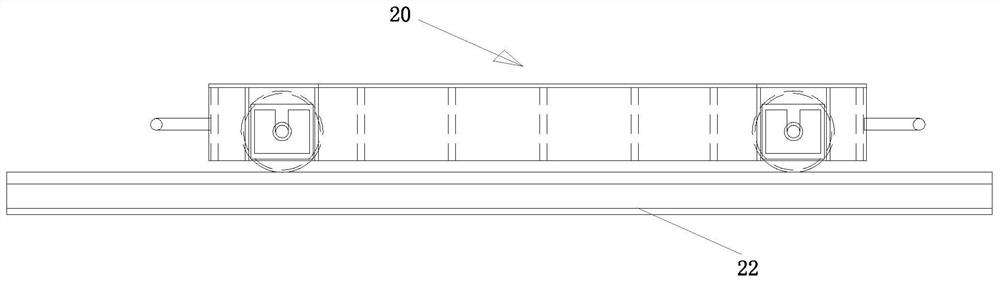

[0057] Such as Figure 1-7 As shown, one of the purposes of the present invention is to provide a transport vehicle 10 with a low center of gravity, which is specially used for transporting assembled box girders of heavy prefabricated arch bridges. The low-center-of-gravity transport vehicle 10 includes a frame 20 made of steel plates and two U-shaped rollers 30 . The two U-shaped rollers 30 are respectively installed to the two ends of the vehicle frame 20 through the shaft 40 and the bearing 50 (not referring to that the two U-shaped rollers 30 are respectively installed on the outermost sides of the two ends of the vehicle frame 20, but referring to the On the whole, the two U-shaped rollers 30 are respectively installed near the two ends of the vehicle frame 20). The distance between the top of t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com