Bluetooth or WiFi controlled 3D printing material conveying system

A 3D printing and conveying system technology, applied in the direction of 3D object support structure, additive manufacturing, manufacturing tools, etc., can solve the problems of uneven material conveying, uneven cladding layer, reduced product processing quality and service life, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

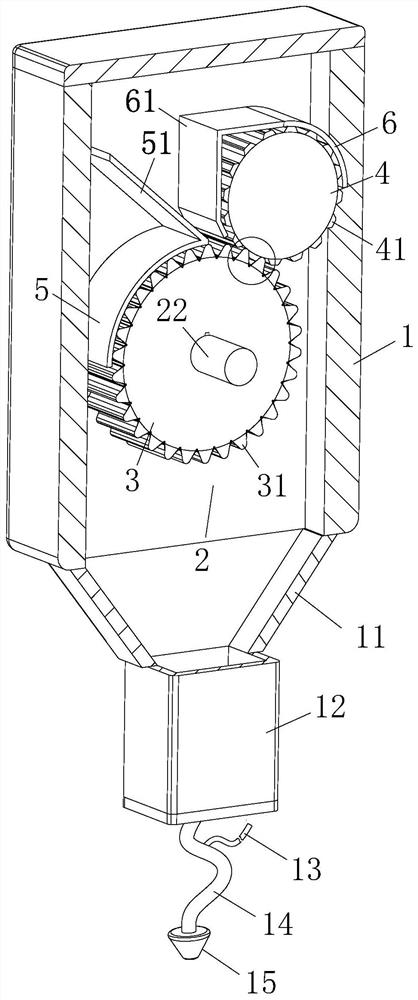

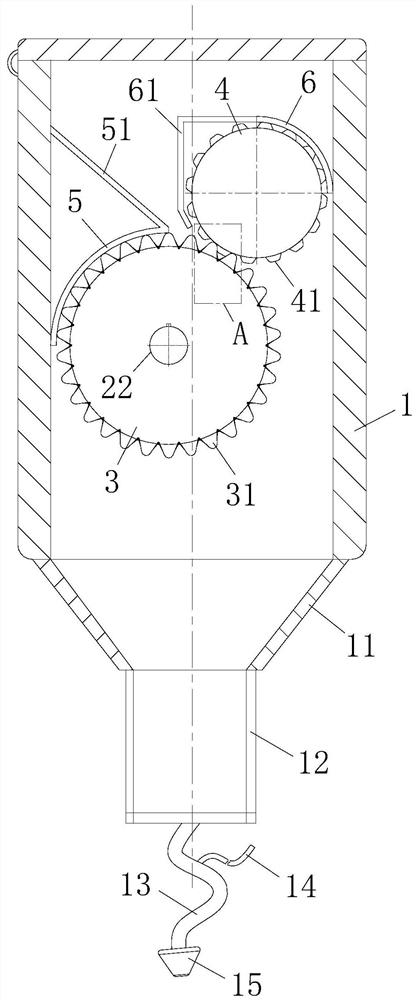

[0026] As an embodiment of the present invention, the top end of the No. 2 arc-shaped plate 6 is provided with a bent protective plate 61 , and the protective plate 61 can protect the side of the driven wheel 4 close to the driving wheel 3 , the top of the No. 1 arc-shaped plate 5 is provided with an inclined plate 51 that gradually moves away from the driven wheel 4; during operation, since the material at the side of the driven wheel 4 close to the driving wheel 3 is in direct contact with the No. 2 gear teeth 41 It is easy to cause the material to adhere to the outer surface of the No. 2 gear teeth 41 or between the adjacent two No. 2 gear teeth 41, thereby affecting the cooperation between the No. 2 gear teeth 41, the No. 1 gear teeth 31 and the conveying groove 32. The top of the No. 2 arc-shaped plate 6 is provided with a bent protective plate 61, so that the protective plate 61 can protect the side of the driven wheel 4 close to the driving wheel 3, so as to reduce the c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com