Necking die

A mold and mold hole technology, which is applied in the field of shrinking molds, can solve the problems of clearance fit, wear through the inner tube, and scrapping of the unit.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

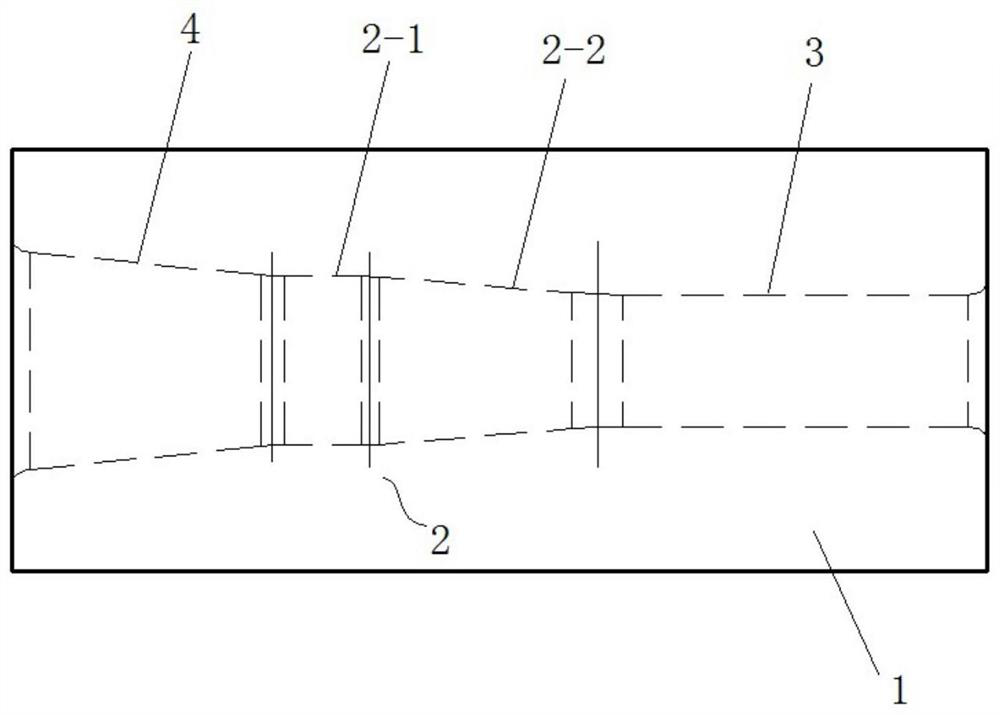

[0032] Such as Figure 1-3 As shown, the present embodiment provides a necking die, which includes,

[0033] The mold body 1 has a mold hole in the mold body 1; the mold hole includes a sizing portion 3 and a diameter-reducing portion 2, and the diameter-reducing portion 2 has an end with a larger diameter and an end with a smaller diameter;

[0034] The diameter reducing part 2 has a first diameter reducing section 2-1 and a second diameter reducing section 2-2, the first diameter reducing section 2-1 is located at the end with a larger diameter, and the first diameter reducing section The diameter of any part of the diameter portion 2-1 is not smaller than the maximum diameter of the second diameter-reducing section 2-2; at least one of the protrusions 2-3 is provided on the first diameter-reducing section 2-1;

[0035] The sizing portion 3 communicates with the diameter-reducing portion 2 and is arranged coaxially, and the sizing portion 3 matches the end of the diameter-r...

Embodiment 2

[0044] Such as Figure 2-3 As shown, the mold body 1 is assembled from four mold bases, which can be processed from Cr12 material, and the surface is heat-treated until the surface hardness reaches HRC55-62. The mold body 1 is assembled from four mold bases, which is selected in consideration of mold accuracy and ease of forming. It can also be assembled from several other mold bases.

[0045] Further, the protrusions 2-3 are arranged on one of the mold bodies. When processing the spinning and compression opening, since the protrusions are provided on one of the mold bodies, it can reduce the spinning resistance, and the inner tube can The outer wall easily forms a stable quasi-annular concave fixing groove to fix its inner liner. Of course, the protrusions 2-3 can also be arranged on a plurality of mold bodies, which can also realize the fixing of the inner liner.

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com