Preparation method of tungsten disulfide/indium sulfide composite nano material

A technology of composite nanomaterials and tungsten disulfide, applied in chemical instruments and methods, chemical/physical processes, water treatment of special compounds, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Weigh 3mmol of tungsten hexachloride in 30mL of absolute ethanol, disperse it ultrasonically, and continue stirring for 30min until the solid is completely dissolved to form solution A;

[0035] Weigh 3mmol indium nitrate and dissolve it in 30mL absolute ethanol, stir for 30min to form solution B;

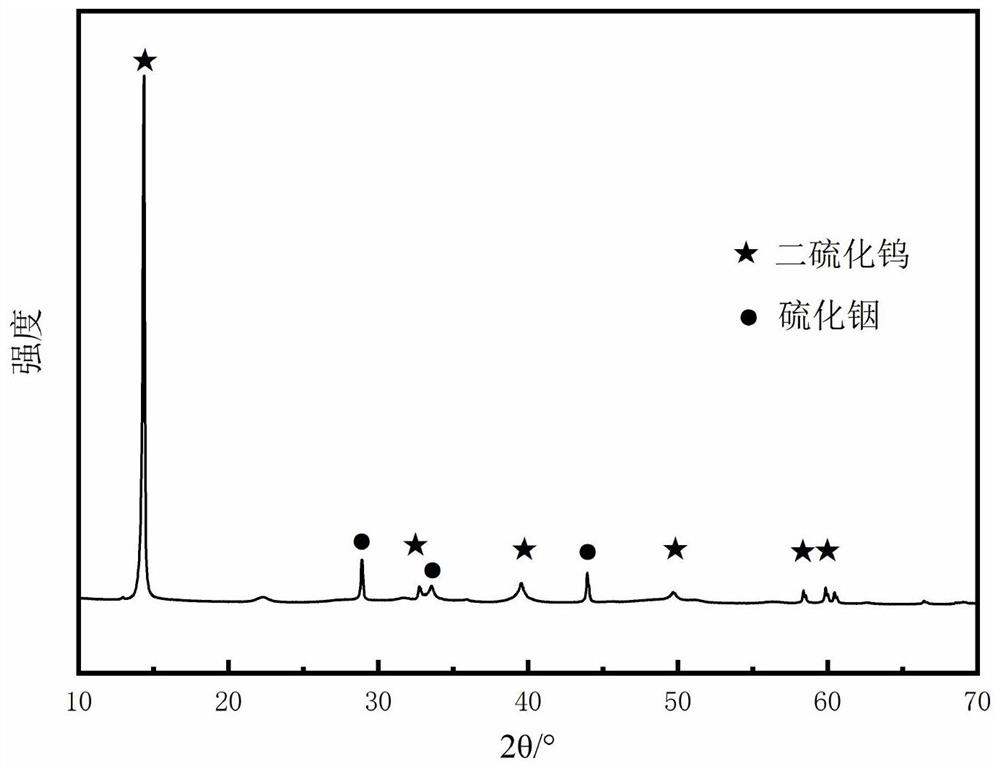

[0036] Slowly add solution B dropwise to solution A, stir for 30min, add 15.75mmol thioacetamide and 1g diallylmethyl dodecyl ammonium bromide, stir for 2h and then transfer to a Teflon-lined In the reaction kettle, add absolute ethanol to about 80% of the liquid level of the reaction kettle, place it in an oven at 180°C for solvothermal reaction for 24 hours, and the obtained product is centrifuged, washed with deionized water and absolute ethanol three times respectively, and the 60 ℃ vacuum drying to obtain a tungsten disulfide / indium sulfide composite nanomaterial with a tungsten-indium molar ratio of 1:1. The XRD pattern of this tungsten disulfide / indium sulfide compos...

Embodiment 2

[0038] Weigh 3mmol of tungsten hexachloride in 30mL of absolute ethanol, disperse it ultrasonically, and continue stirring for 30min until the solid is completely dissolved to form solution A;

[0039] Weigh 6mmol of indium nitrate and dissolve it in 30mL of absolute ethanol, stir for 30min to form solution B;

[0040] Slowly add solution B dropwise to solution A, stir for 30min, add 22.5mmol thioacetamide and 1g of diallylmethyl dodecyl ammonium bromide, stir for 2h and transfer to a polytetrafluoroethylene-lined In the reaction kettle, add absolute ethanol to about 80% of the liquid level of the reaction kettle, place it in an oven at 180°C for solvothermal reaction for 24 hours, and the obtained product is centrifuged, washed with deionized water and absolute ethanol three times respectively, and the 60 °C vacuum drying to obtain a tungsten-indium molar ratio of 1:2 tungsten disulfide / indium sulfide composite nanomaterials.

Embodiment 3

[0042] Weigh 1.5mmol of tungsten hexachloride in 30mL of absolute ethanol, ultrasonically disperse, and continue to stir for 30min until the solid is completely dissolved to form solution A;

[0043] Weigh 60mmol indium nitrate and dissolve it in 300mL absolute ethanol, stir for 30min to form solution B;

[0044] Slowly add solution B to solution A dropwise, stir for 30min, add 15.75mmol thioacetamide and 0.5g diallylmethyl dodecyl ammonium bromide, stir for 2h and then transfer to a polytetrafluoroethylene liner Add absolute ethanol to about 80% of the liquid level of the reactor, place it in an oven at 120°C for solvothermal reaction for 48 hours, and centrifuge the obtained product, wash with deionized water and absolute ethanol three times respectively, Vacuum drying at 60°C yielded a tungsten-indium molar ratio of 0.025:1 tungsten disulfide / indium sulfide composite nanomaterial.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com