Molasses adding system and use method thereof

A molasses and heated technology, which is applied in the field of molasses addition systems, can solve the problems of reducing the amount of molasses added, poor fluidity of molasses, preventing molasses absorption, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] In this embodiment, a molasses adding system is proposed, which is used to add heated molasses to the heated feed pellets and tablet materials, so as to ensure the amount of molasses added, so that the finished feed formed after adding molasses The nutritional value is better. Among them, the tableting material is mixed into the feed granules, which can make the finished feed have various ingredients, better taste and higher nutritional value. In this embodiment, the tableting material is a mixture of corn flakes, wheat flakes and barley flakes.

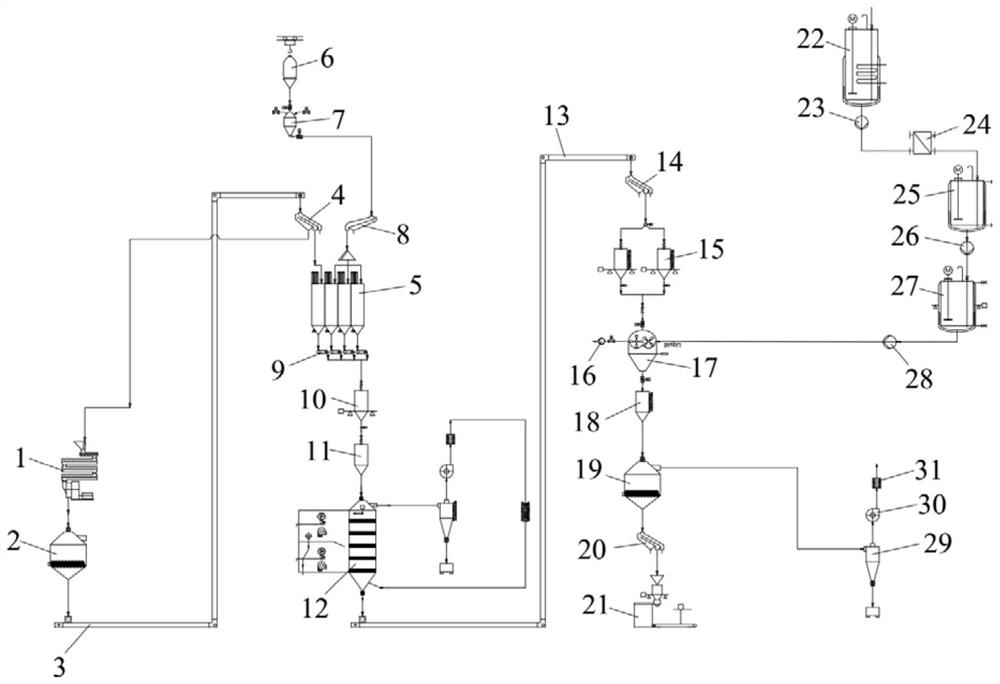

[0054] Specifically, such as figure 1As shown, the molasses adding system includes a batching equipment 9 for batching feed granules and tablet materials, a heater 12 for heating feed granules and tablet materials, a weighing piece 15, a heat exchanger 24 for heating molasses, A weighing tank 27 for weighing molasses, a daily tank 25 for storing heated molasses used every day, a first driving member 28, a vacuum sprayer 17 a...

Embodiment 2

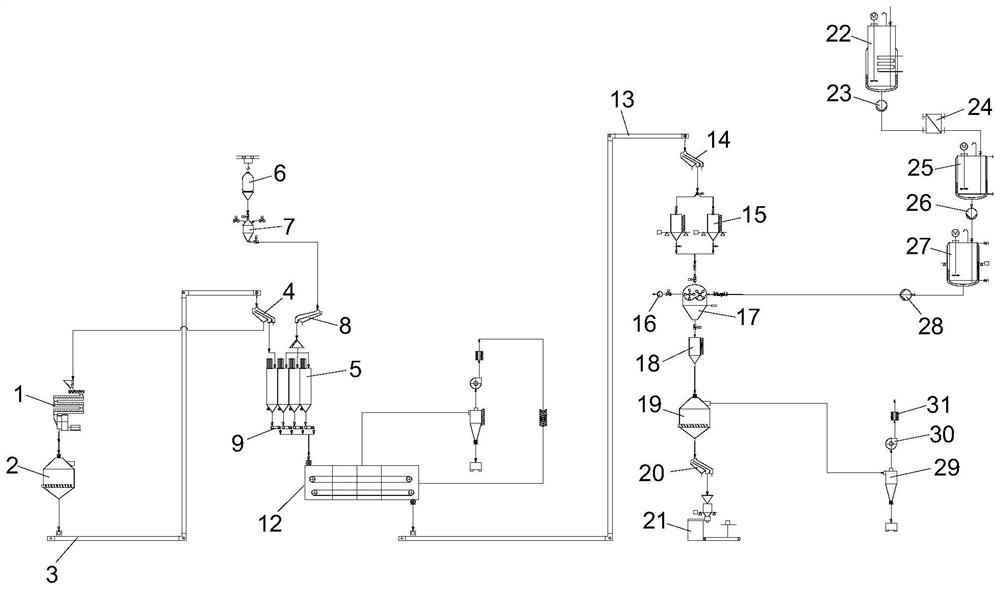

[0067] In this embodiment, a kind of molasses adding system is proposed, such as figure 2 As shown, the difference between the molasses adding system in the present embodiment and the first embodiment is that in the present embodiment, the heater 12 is a continuous heating system, and there is no device between the batching equipment 9 and the heater 12 for Weigh the batching scale 10 and the first buffer bucket 11 of the feed granules and tablet materials. Wherein, since the batching equipment 9 can not only be used for batching feed pellets and tabletting materials, but also can play the role of premixed feed pellets and tabletting materials, so that the feed pellets and tabletting materials directly entering the heater 12 by the batching equipment 9 The material is relatively uniform, so that it can be directly and continuously heated.

Embodiment 3

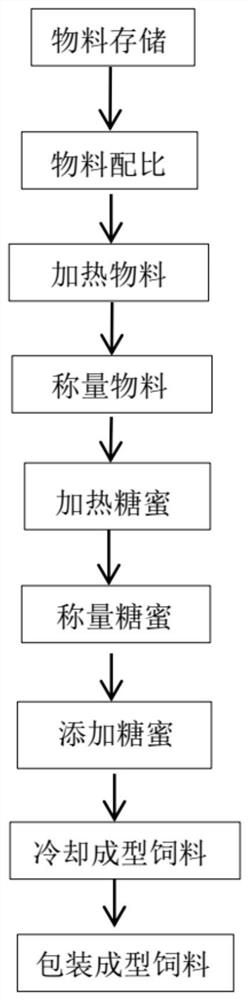

[0069] In this embodiment, a method for using the molasses adding system in Embodiment 1 is proposed, such as image 3 As shown, it includes the following steps: material storage: store feed granules and tabletting materials in the storage bin 5; material proportioning: carry out batch batching of feed granules and tabletting materials through batching equipment 9, and feed granules after batching and tableting materials go through the batching scale 10 and the first buffer bucket 11 to the heater 12; heating materials: use the heater 12 batches to heat the feed granules and tableting materials after batching; weighing materials: use weighing parts 15 Measure the weight G of the heated feed granules and tablet materials; heating molasses: heat the molasses through the heat exchanger 24; In the tank 27, according to the weight G, the weighing tank 27 weighs the weight g of the heated molasses matched with it; add molasses: make the first driver 28 move the molasses in the weigh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com