Multistage juice and peel separating device for passion fruits

A multi-stage separation and passion fruit technology, applied in juice extraction, food science, application, etc., can solve problems such as waste, high labor cost, and inability to realize passion fruit peel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

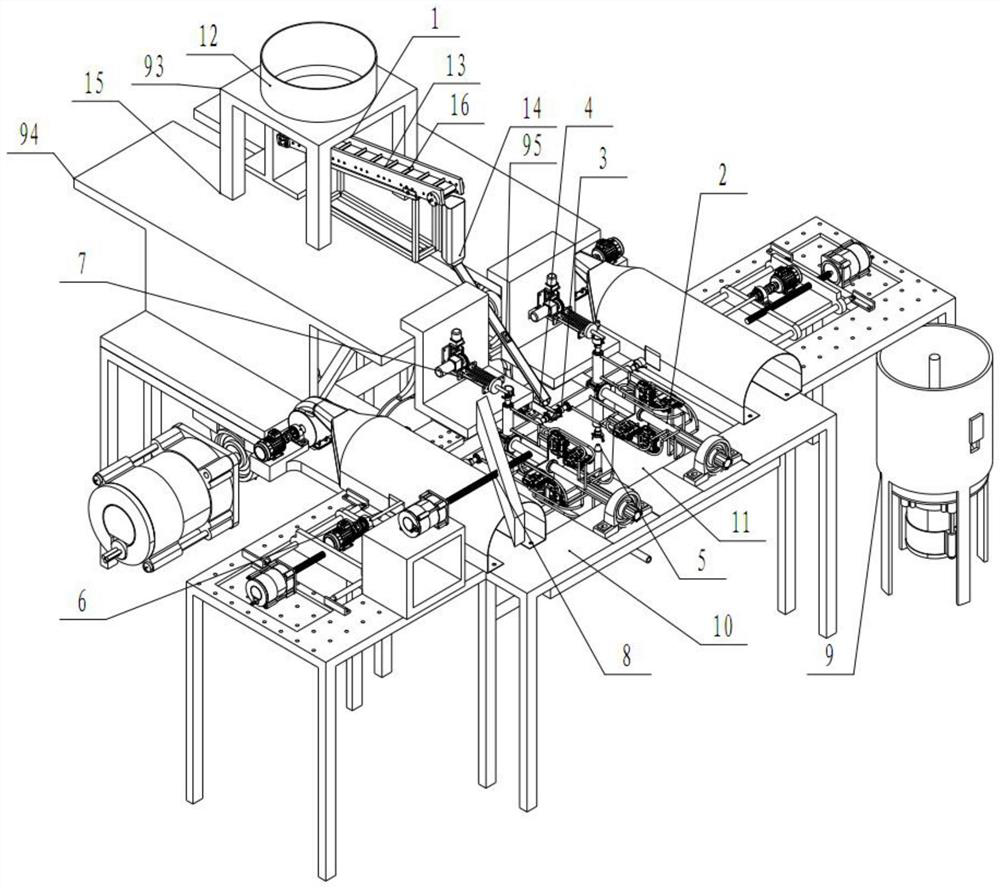

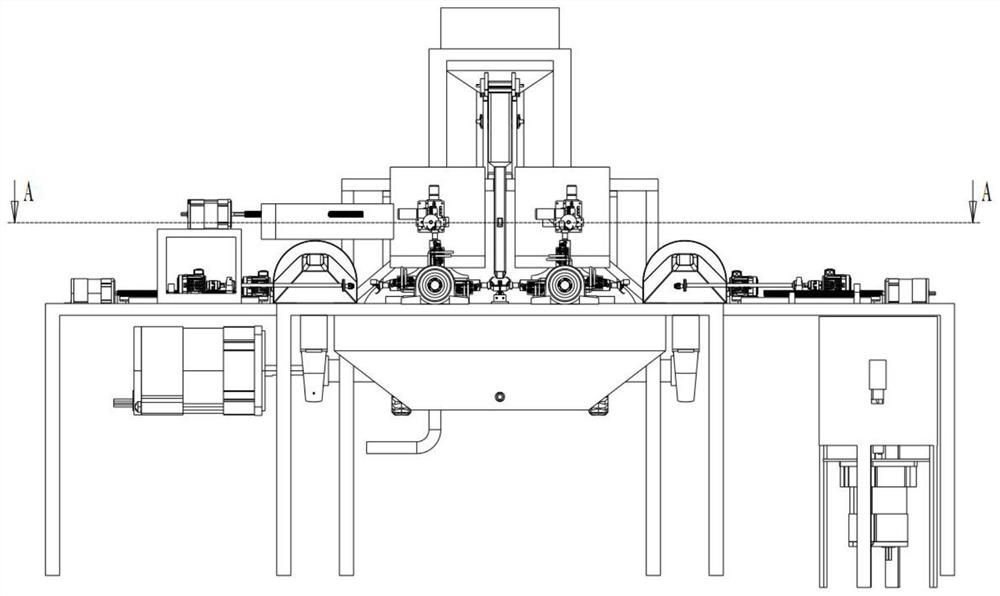

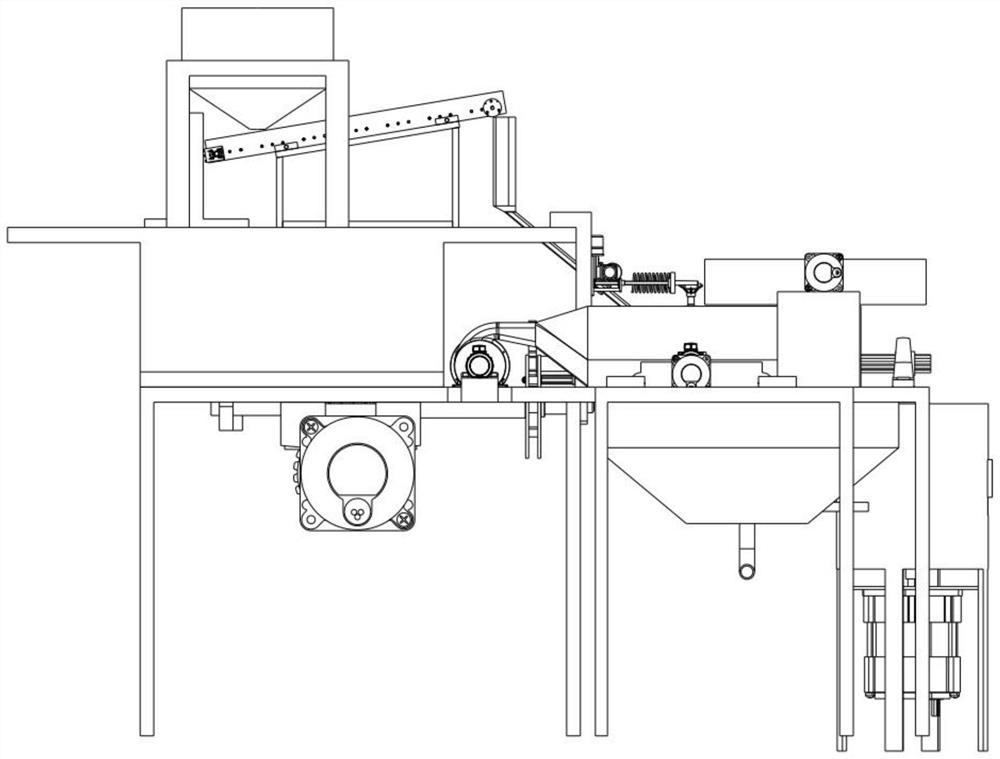

[0046] Embodiment 1: as Figure 1-20 As shown, a passion fruit juice peel multi-stage separation device, including a feeding mechanism 1, a main shaft power mechanism 2, a grab mechanism 3, a linear cutting mechanism 4, a juice separation mechanism 5, a sponge layer separation mechanism 6, an ejection mechanism 7, a Into the drum mechanism 8 and the peel separation mechanism 9, the feeding mechanism 1 is installed above the rear side of the support table 10, two main shaft power mechanisms 2 are used, and are symmetrically arranged on the left and right sides of the support table 10, and each main shaft power mechanism 2 is installed radially There are four grab mechanisms 3 uniformly distributed in the circumferential direction, openings 11 are set on the support platform 10 corresponding to the grab mechanism 3, and the linear cutting mechanism 4 is installed on the back side of the support platform 10, and can extend into the inner sides of the two spindle power mechanisms 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com