Reserved chamber simulating test piece manufacturing die assembly and method used for manufacturing test piece

A technology of mold assembly and test piece, which is applied in the field of simulated test piece mold assembly and its use in the preparation of simulated test pieces, can solve the problems of sample quality deterioration, sample damage, and difficulty in grasping the percussion force, etc. Achieve the effects of reducing impact and damage, easy demoulding process, and easy demoulding operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

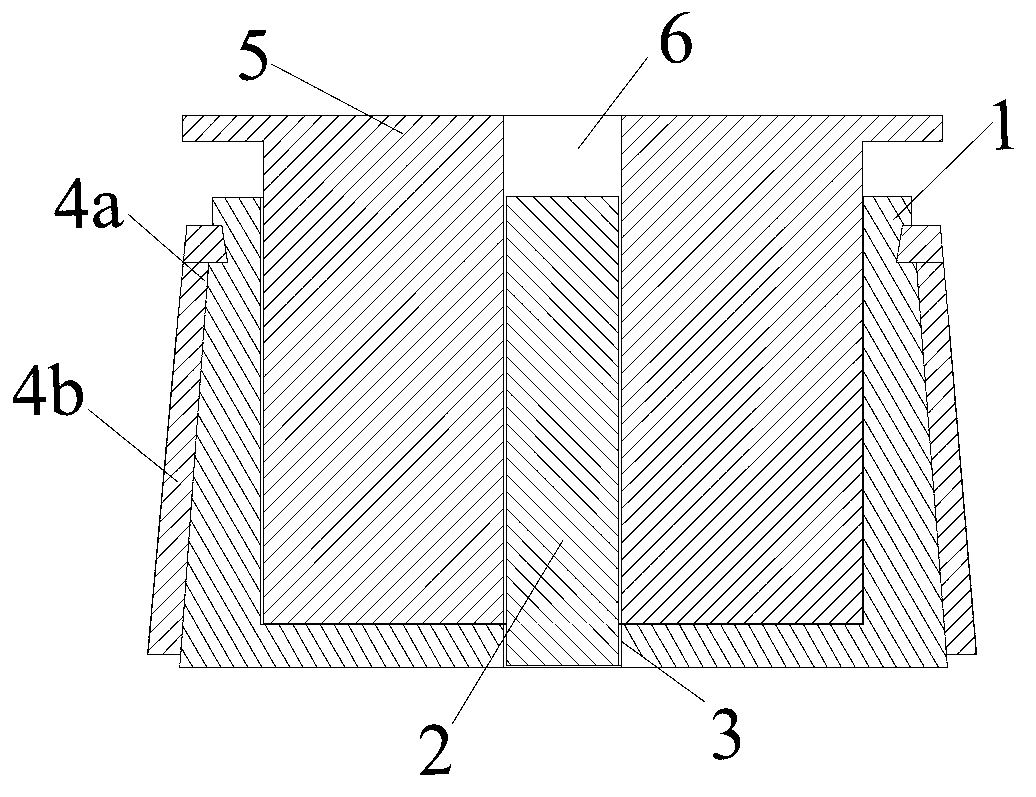

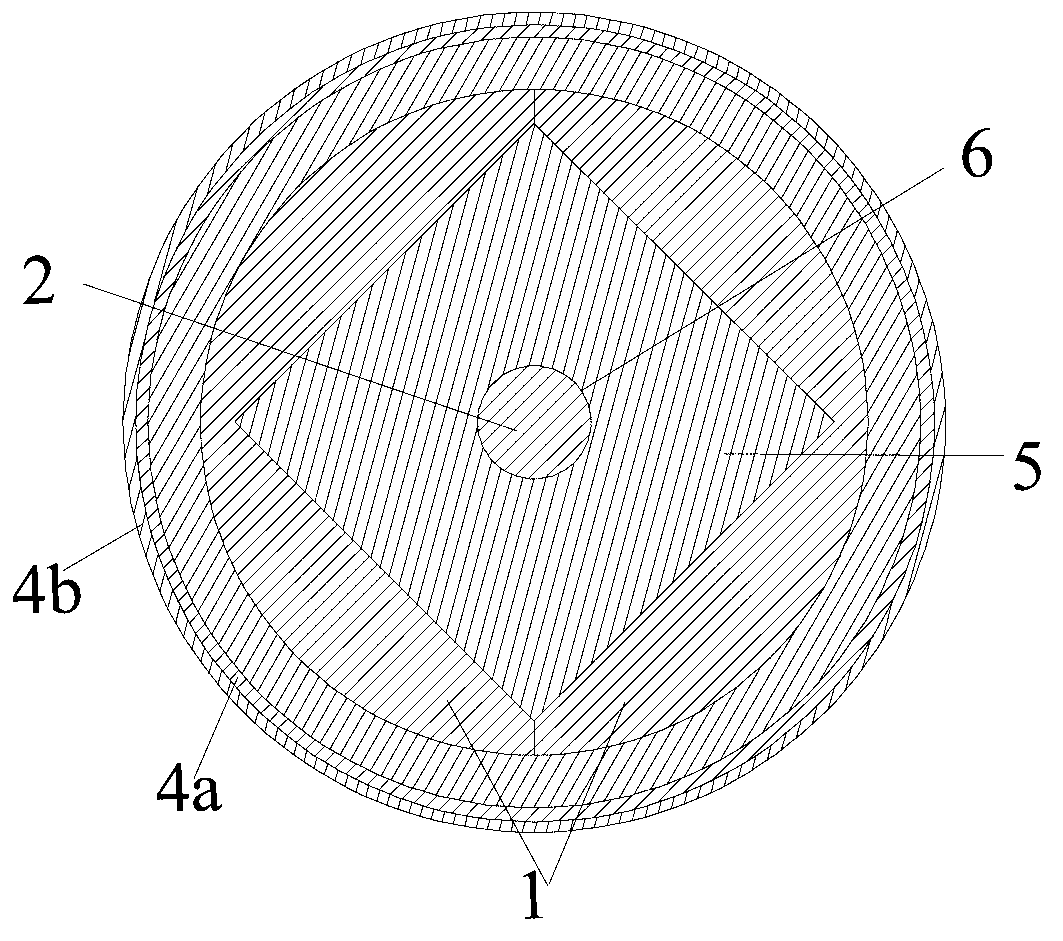

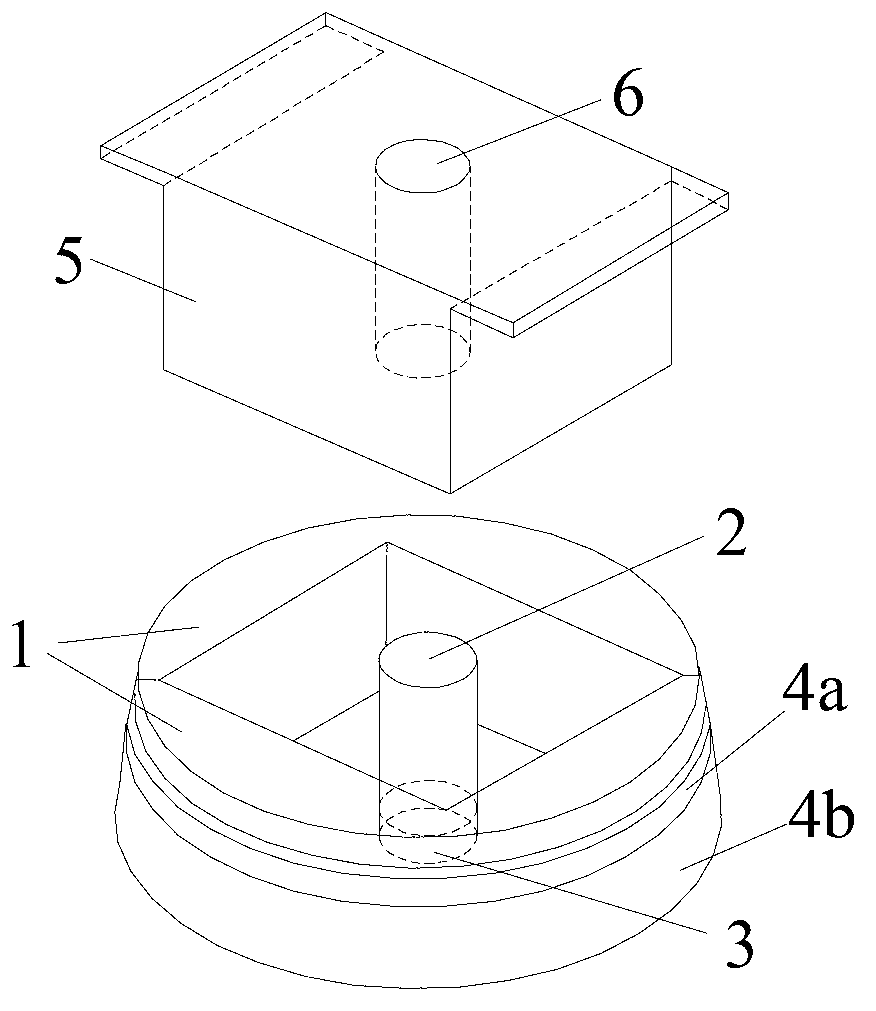

[0040] In conjunction with the accompanying drawings, the embodiment of the prepared mold assembly of the reserved chamber simulation test piece of the present invention is described in detail as follows:

[0041] Such as figure 1 As shown, the preparation mold assembly of the reserved chamber simulation test piece of the present invention includes a model shell 1 of a split structure composed of two symmetrical parts, a solid cylinder 2, a circular through hole 3, and a first clamp 4a , the second clamp 4b, the pressure bearing plate 5, and the cylindrical housing chamber 6. An annular groove is arranged on the outer peripheral surface of the upper part of the above-mentioned model shell 1, and the above-mentioned annular groove is in the shape of a rounded truncated cone as a whole, and the diameter of its cross section is from thick to thin from top to bottom; the above-mentioned clamp includes a first clamp 4a and The second clamp 4b, wherein the first clamp 4a is an open...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com