Residual film pickup device

A residual film picking and chain rake technology, applied in the field of farmland residual film recycling devices, can solve the problems of easy tearing of mulch, easy winding, and increased overall power consumption.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

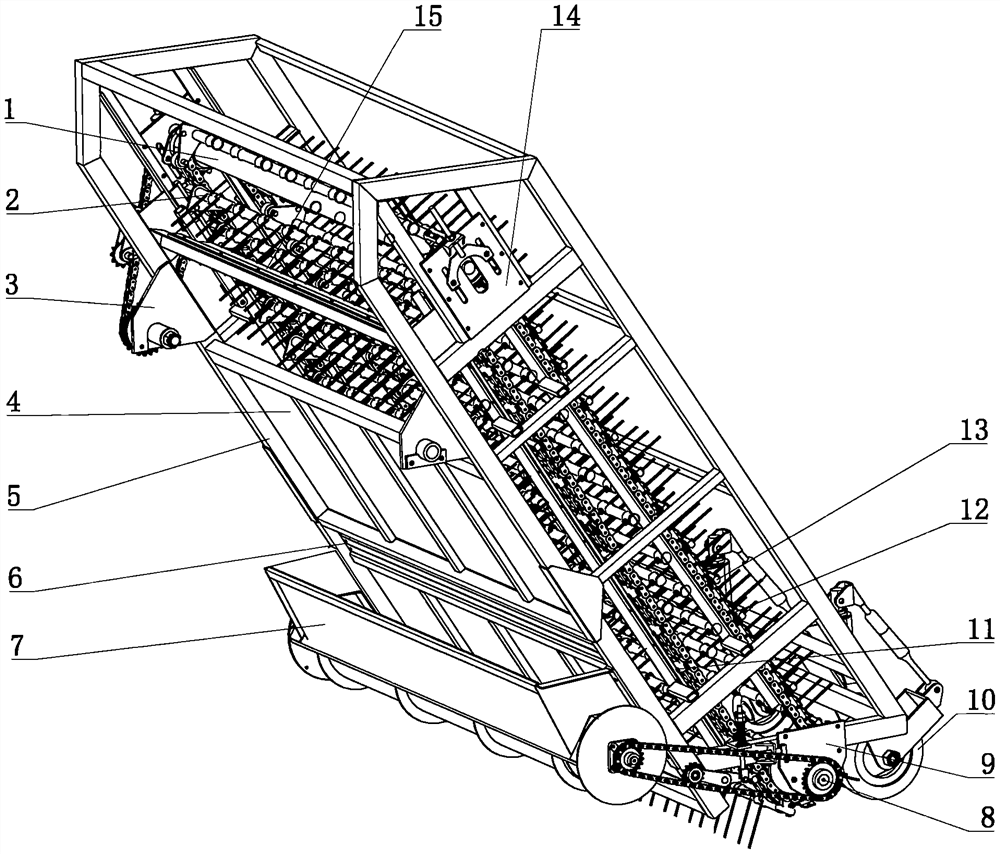

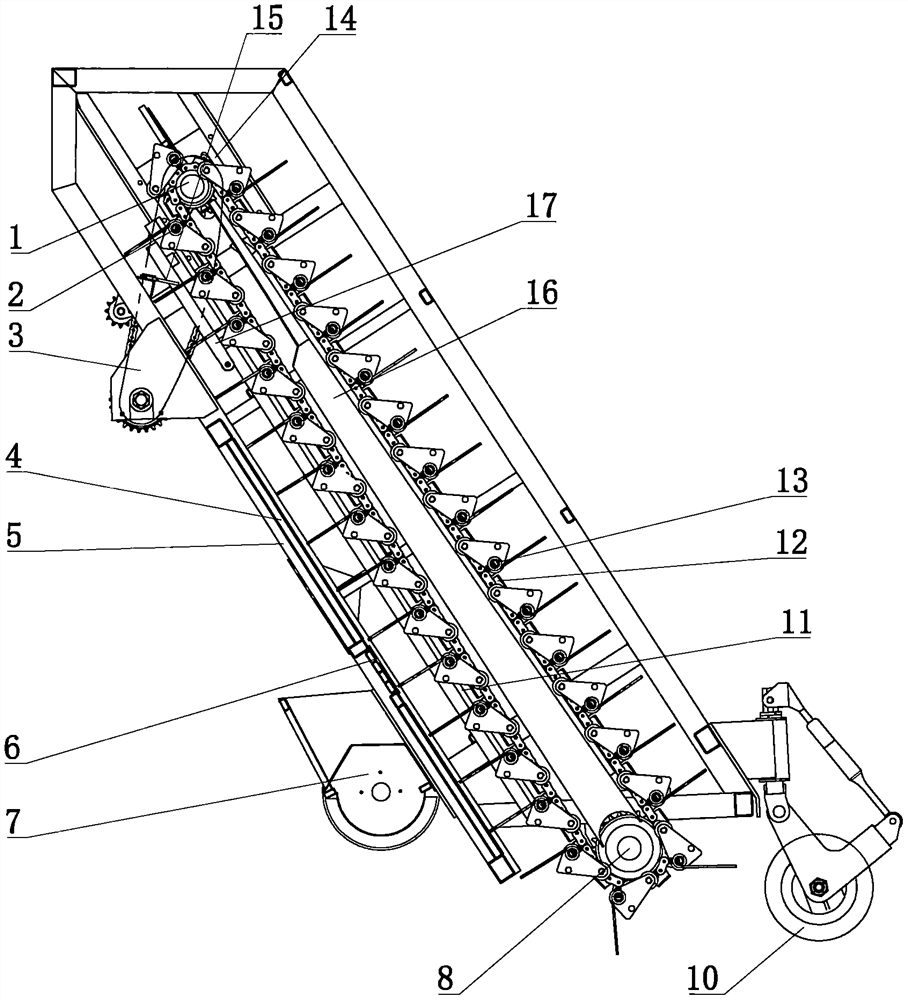

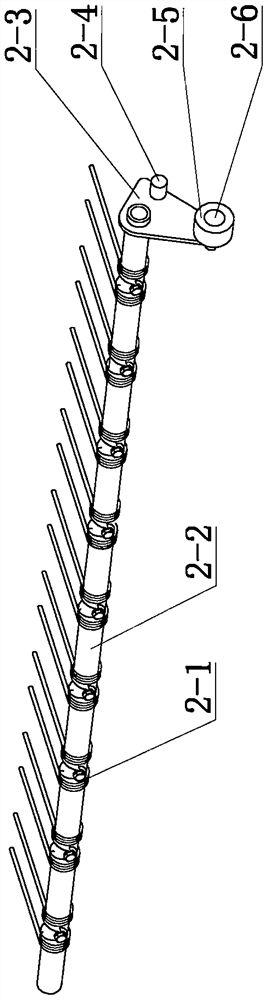

[0025] Embodiment: refer to attached Figure 1~6 , the present invention consists of a chain rake frame 5, a film pick-up mechanism, a miscellaneous discharge flap and a depth-limiting wheel 10. Under the upper part of the chain rake frame, the described miscellaneous removal device is arranged on the chain rake frame 5, and the described depth-gauge wheel 10 is arranged in front of the lower part of the chain rake frame 5; 2. Chain rake hanging plate 3, supporting plate 4, chain rake frame 5, miscellaneous discharge flap 6, chain rake lower shaft 8, chain rake lower shaft plate 9, nylon slide plate 11, bending conveyor chain 12, hinged short shaft 13 , a chain rake upper shaft plate 14, a limit block 16, and a direction-changing slideway 17; The rake hanging plate 3 and the supporting plate 4 are arranged on the chain rake frame 5, and the described debris removal flap 6 is arranged on the chain rake frame 5; the chain rake lower shaft plate 9, the chain rake upper shaft pla...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com