3D camera

A camera and 3D technology, applied in the camera field, can solve problems such as high-altitude operation danger, cumbersome operation, and easy accumulation of dust in the 3D camera area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

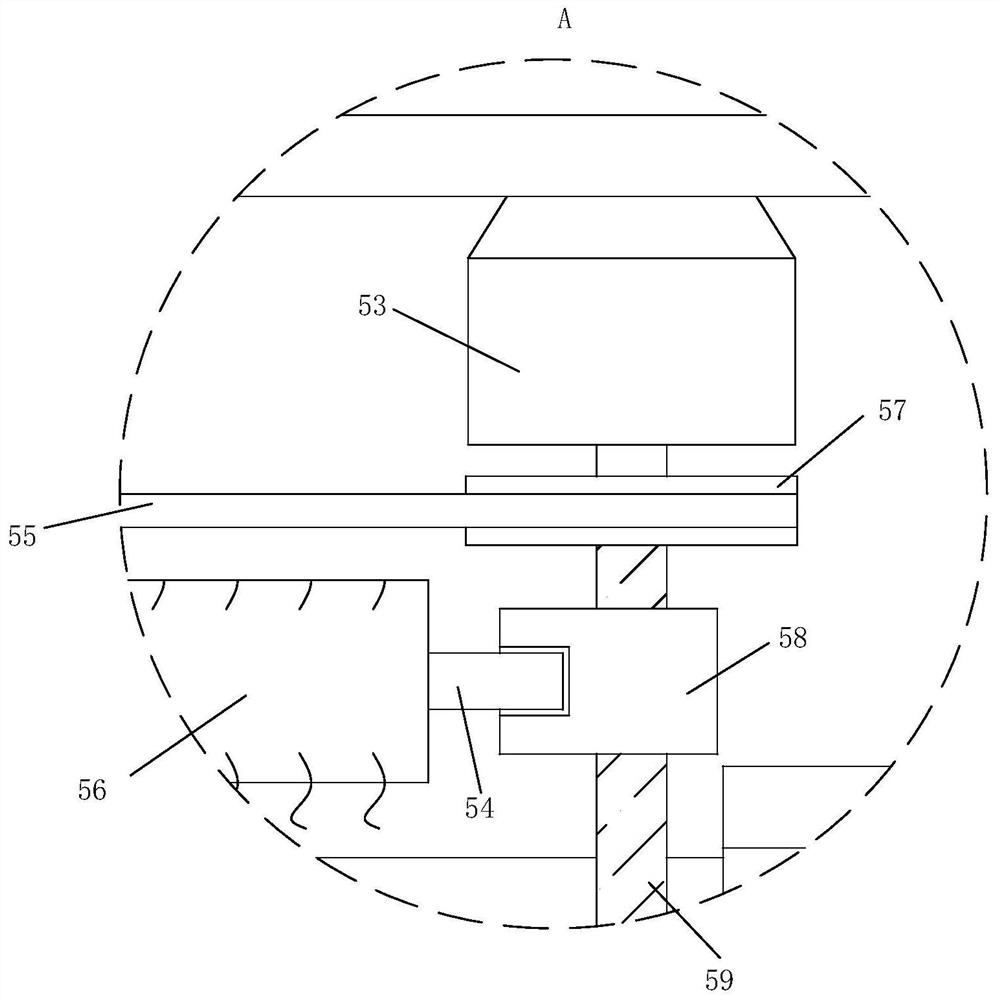

[0018] Please refer to figure 1 , figure 2 and image 3 , a 3D camera, comprising a rectangular housing 1, a camera lens 2, an adjustment structure 3, a glass sheet blowing structure 4 and a wiping structure 5, one side of the rectangular housing 1 is open, and the rectangular housing 1 Camera lens 2 is installed close to the inside of the opening, and the glass sheet blowing structure 4 is connected to the rectangular housing 1. The glass sheet blowing structure 4 includes a ventilation pipe 41, an induced fan 42, a T-shaped air guide pipe 43 and a glass sheet 44, The glass sheet 44 is installed in the inside of the rectangular housing 1 close to the open area. The two sides of the rectangular housing 1 are respectively equipped with induced draft fans 42. The lateral side walls of the air guide pipe 43 are respectively connected to several ventila...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com