Low-temperature electrode plate, preparation method thereof and low-temperature lithium battery

A low-temperature electrode and negative electrode technology, applied in the direction of electrode carrier/current collector, battery electrode, secondary battery, etc., can solve the problems of short warranty period, easy oxidation, and increased production cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0046] This embodiment provides a method for preparing a low-temperature electrode sheet and a low-temperature battery.

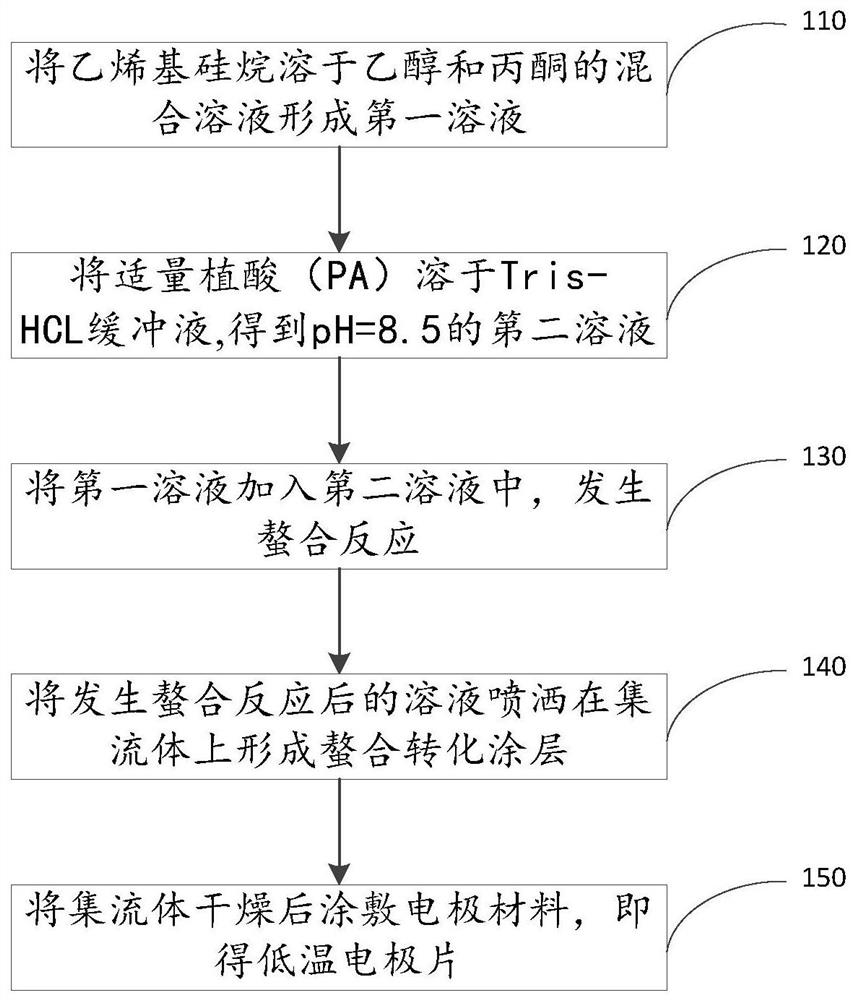

[0047] Preparation methods include:

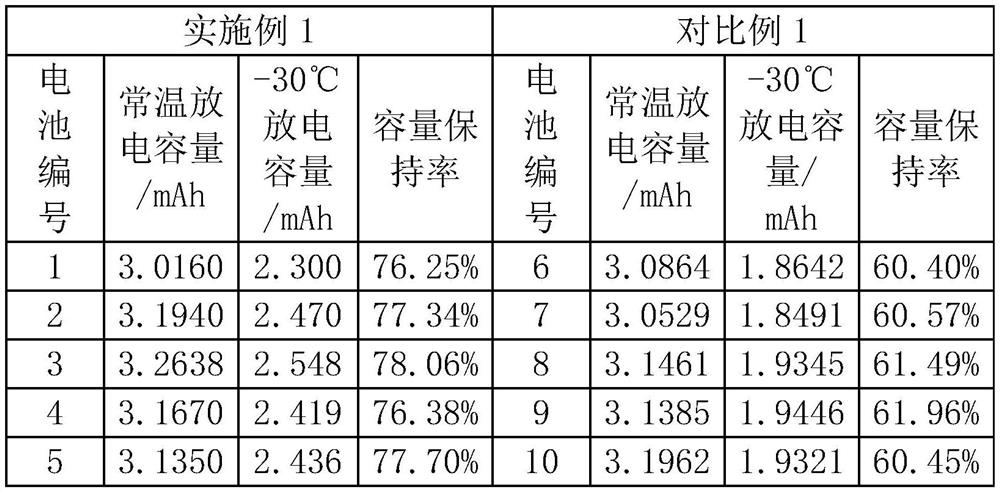

[0048] Dissolve vinyl silane in a mixed solution of ethanol and acetone with a mass ratio of 10:1 to form a first solution with a concentration of 0.004g / ml; dissolve phytic acid in Tris-HCL buffer to form a second solution with pH=8.5 ; Wherein, the mass ratio of the phytic acid added in the second solution to the vinyl silane added in the first solution is 1:2. The first solution is added to the second solution, and a chelation reaction occurs; the solution after the chelation reaction is sprayed on the foamed aluminum and the foamed copper to form a chelation conversion coating; the positive electrode active material is manganese-nickel-cobalt composite oxide 1. Coating the electrode material without binder on the dried aluminum foam to prepare the positive electrode sheet; coating the electrode material with carbon...

Embodiment 2

[0051] This embodiment provides a method for preparing a low-temperature electrode sheet and a low-temperature battery.

[0052] Preparation methods include:

[0053] Dissolve vinylsilane in a mixed solution of ethanol and acetone at a mass ratio of 5:1 to form a first solution with a concentration of 0.012g / ml; dissolve phytic acid in Tris-HCL buffer to form a second solution with pH=8.5 ; Wherein, the mass ratio of the phytic acid added in the second solution to the vinyl silane added in the first solution is 1:2. The first solution is added to the second solution to cause a chelation reaction; the solution after the chelation reaction is sprayed on the foamed aluminum and the foamed copper to form a chelation conversion coating; the positive electrode active material is an aluminum-cobalt-nickel composite oxide 1. Coating the electrode material without binder on the dried aluminum foil to prepare positive electrode sheet; coating the electrode material with carbon material...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com