High-nickel cobalt-free quaternary positive electrode material and preparation method thereof

A positive electrode material, high nickel technology, applied in positive electrodes, electrical components, battery electrodes, etc., can solve the problems of decreased specific capacity and cycle performance, difficult to industrialize, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

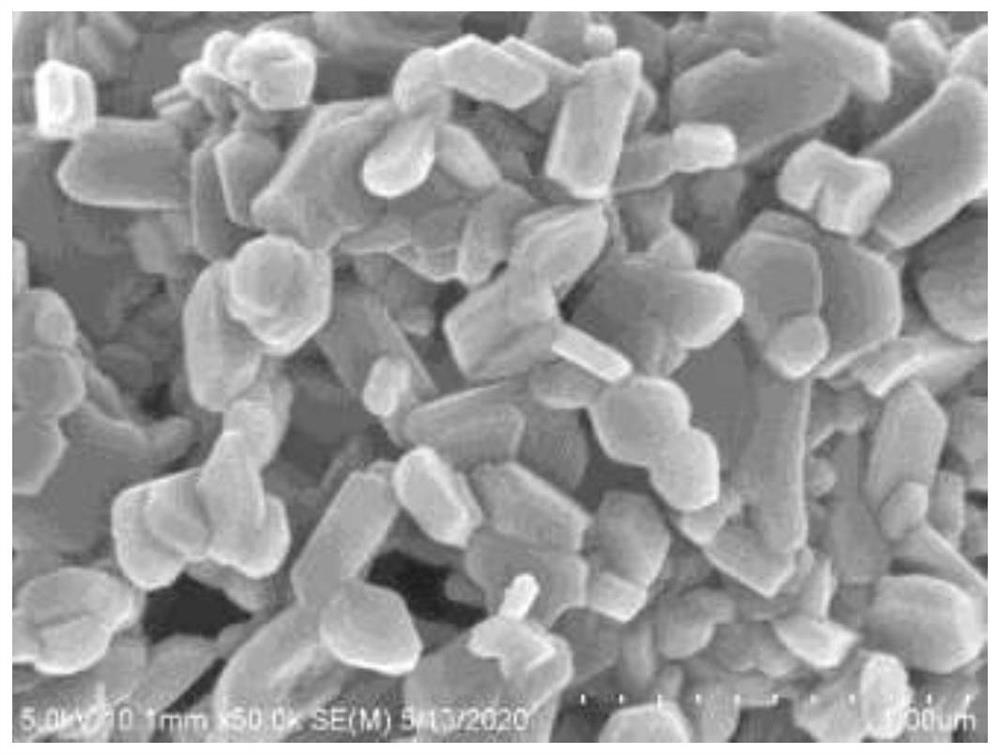

[0027] Add nickel sulfate and manganese sulfate into deionized water according to the metal ion molar ratio Ni:Mn=0.95:0.03 to obtain a mixed salt solution, in which the total concentration of metal ions is 2.0mol / L; configure 4.0mol / L NaOH solution. While stirring, the mixed salt solution is added to the reaction kettle filled with 30% bottom liquid, and the drop rate of the NaOH solution is adjusted so that the pH of the solution in the reaction kettle is stable at 11.3, and the reaction temperature is set at 50°C. Oxidation, the whole reaction process continuously feeds N into the solution 2 . After reacting for 20 h, the solution was centrifuged, and the precipitate was washed several times with deionized water, and Ni was obtained after drying. 0.95 mn 0.03 (OH) 1.96 Precursor. Weigh an appropriate amount of the precursor, Al(OH) 3 , Mg(OH) 2 and LiOH, wherein the molar ratio of metal elements is Ni:Mn:Al:Mg:Li=0.95:0.03:0.01:0.01:1.05, the four are uniformly mixed,...

Embodiment 2

[0029] Add nickel sulfate, manganese sulfate, and magnesium sulfate into deionized water according to the molar ratio of metal ions Ni:Mn:Mg=0.9:0.08:0.01 to obtain a mixed salt solution, in which the total concentration of metal ions is 5.0mol / L; configure 10.0mol / L of KOH solution. While stirring, add the mixed salt solution into the reaction kettle filled with 10% bottom liquid, adjust the drop rate of the KOH solution, so that the pH of the solution in the reaction kettle is stable at 12.0, and the reaction temperature is set at 40°C. Oxidation, throughout the reaction, continuously feed Ar into the solution. After reacting for 40 h, the solution was centrifuged, and the precipitate was washed several times with deionized water, and Ni was obtained after drying. 0.9 mn 0.08 Mg 0.01 (OH) 1.98 Precursor. Weigh an appropriate amount of the precursor, ZrO 2 and LiNO 3 , wherein the molar ratio of metal elements is Ni:Mn:Mg:Zr:Li=0.9:0.08:0.01:0.01:1.08, the three are e...

Embodiment 3

[0031]Add nickel sulfate and manganese sulfate into deionized water according to the metal ion molar ratio Ni:Mn=0.8:0.18 to obtain a mixed salt solution, in which the total concentration of metal ions is 1mol / L; configure 2.0mol / L NaOH solution. While stirring, the mixed salt solution is added to the reaction kettle filled with 20% bottom liquid, and the drop rate of the NaOH solution is adjusted so that the pH of the solution in the reaction kettle is stable at 11, and the reaction temperature is set at 60°C. Oxidation, the whole reaction process continuously feeds N into the solution 2 . After reacting for 10 h, the solution was centrifuged, and the precipitate was washed several times with deionized water, and Ni was obtained after drying. 0.8 mn 0.18 (OH) 1.96 Precursor. Weigh an appropriate amount of the precursor, TiO 2 、WO 3 and Li 2 CO 3 , wherein the molar ratio of metal elements is Ni:Mn:Ti:W:Li=0.8:0.18:0.01:0.01:1.1, the four are evenly mixed, placed in a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com