Gas relay for realizing intelligent tripping of transformer and gas protection method

A relay and transformer technology, applied in the field of transformer protection devices, can solve the problems of prolonging the decision-making cycle and low intelligence level

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

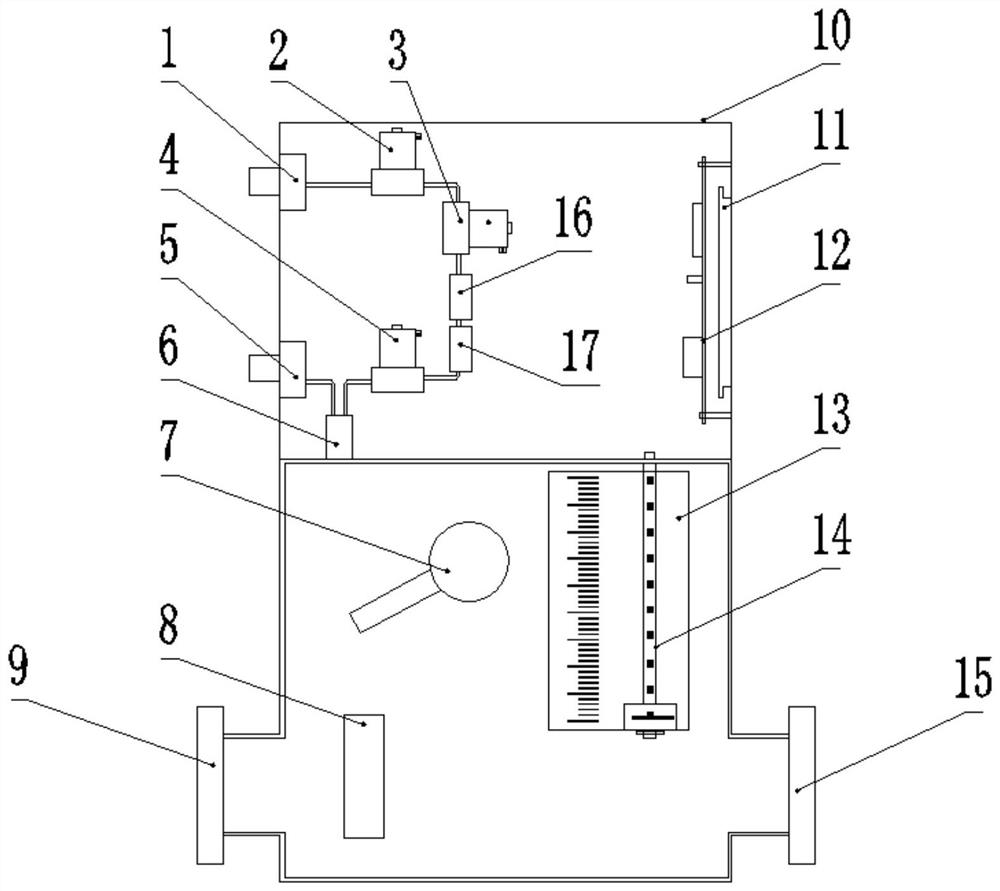

[0066] Embodiment 1: A gas relay

[0067] Such as figure 1 As shown, the present invention provides a gas relay, including: a main cavity and a measurement and control cavity, the main cavity is connected to the transformer body through the first flange interface 9, connected to the oil conservator through the second flange interface 15, and the measurement and control cavity A cavity is provided above the body cavity and is formed by a protective cover 10 for protecting components inside it.

[0068] The main chamber includes: a light gas level float switch 7, a float sensor 14 and a flow valve 8; the measurement and control chamber includes: a control module 12 and a combustible gas content detection module.

[0069] The light gas liquid level float switch 7 is respectively connected to the background system and the control module 12. If the gas volume of the gas relay reaches the light gas alarm threshold, the light gas liquid level float switch 7 sends a light gas alarm t...

Embodiment 2

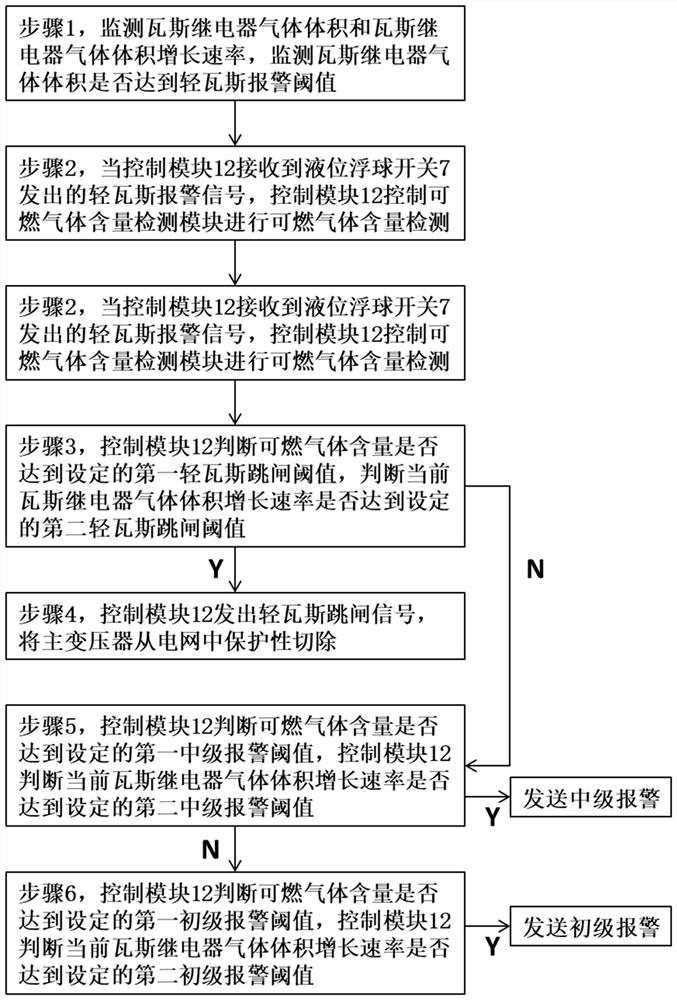

[0080] Embodiment 2: a kind of gas protection method

[0081] Such as figure 2 As shown, the present invention also provides a gas protection method based on the gas relay described in Embodiment 1, comprising the following steps:

[0082] Step 1, the control module 12 is connected to the float sensor 14 to monitor the gas volume of the gas relay and the growth rate of the gas volume of the gas relay; the control module 12 is connected to the liquid level float switch 7 to monitor whether the gas volume of the gas relay reaches the light gas alarm The threshold value makes the liquid level float switch 7 send out a light gas alarm signal.

[0083] Those skilled in the art can arbitrarily set the light gas alarm threshold according to the actual situation of the transformer site. In order to clearly illustrate this embodiment, preferably but not limitatively, the light gas alarm threshold is set to 250mL.

[0084] Specifically, monitoring the gas volume growth rate of the Bu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com