Relay protection test wire box

A relay protection and test line technology, applied in the measurement of electrical variables, components of electrical measuring instruments, measuring devices, etc., can solve the problems of time-consuming and laborious, easy confusion, and scattered storage of short-circuit wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The present invention will be further described below with reference to the accompanying drawings and specific embodiments.

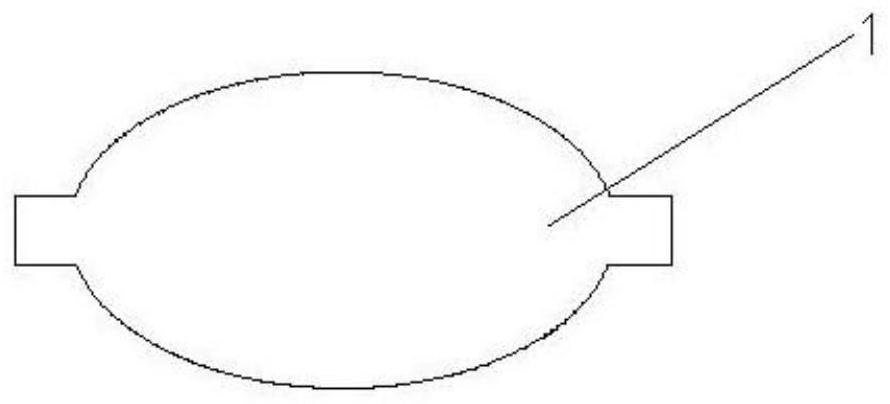

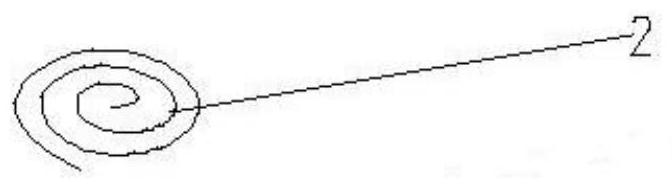

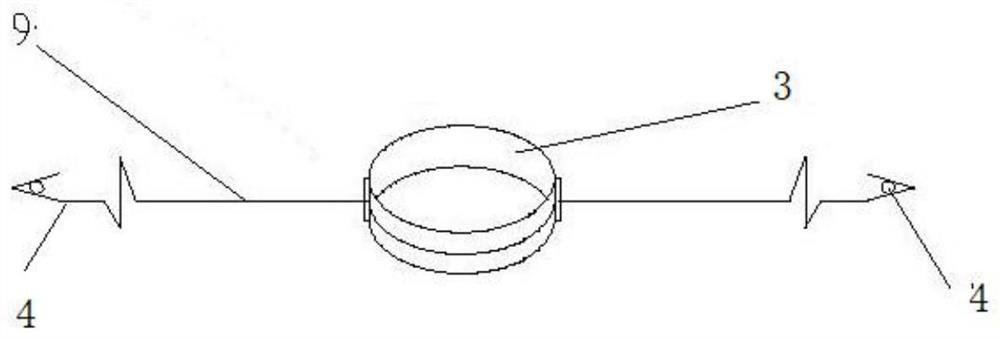

[0021] like Figure 1-4 As shown, the relay protection test wire box of the present invention includes a plurality of test wire automatic recovery boxes 16, and each test wire automatic recovery box 16 includes: upper covers 1, 2, wire pulleys 3, wire ends 4, wire outlet 5, A fixed column 6, a lower cover 7, a circular guide groove 8, and a wire 9, each end of the wire 9 is connected with a wire head 4, the inner sides of the upper cover 1 and the lower cover 7 are provided with a circular guide groove 8, and the lower cover is provided with a circular guide groove 8. The center of the circular guide groove 8 of 7 is provided with a fixed column 6 that is vertically and fixedly connected to the lower cover. And the circular guide groove 8 of the lower cover 7 only has the freedom of rotation, the mainspring 2 is arranged inside the wire wheel 3,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com